Laser marking machine and positioning marking method

A laser marking machine and laser marking technology, applied in laser welding equipment, welding equipment, metal processing and other directions, can solve the problems of low recognition degree of CCD camera, completely coaxial camera center, and unsatisfactory marking effect, etc. It is easy to analyze the reasons and improve the positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

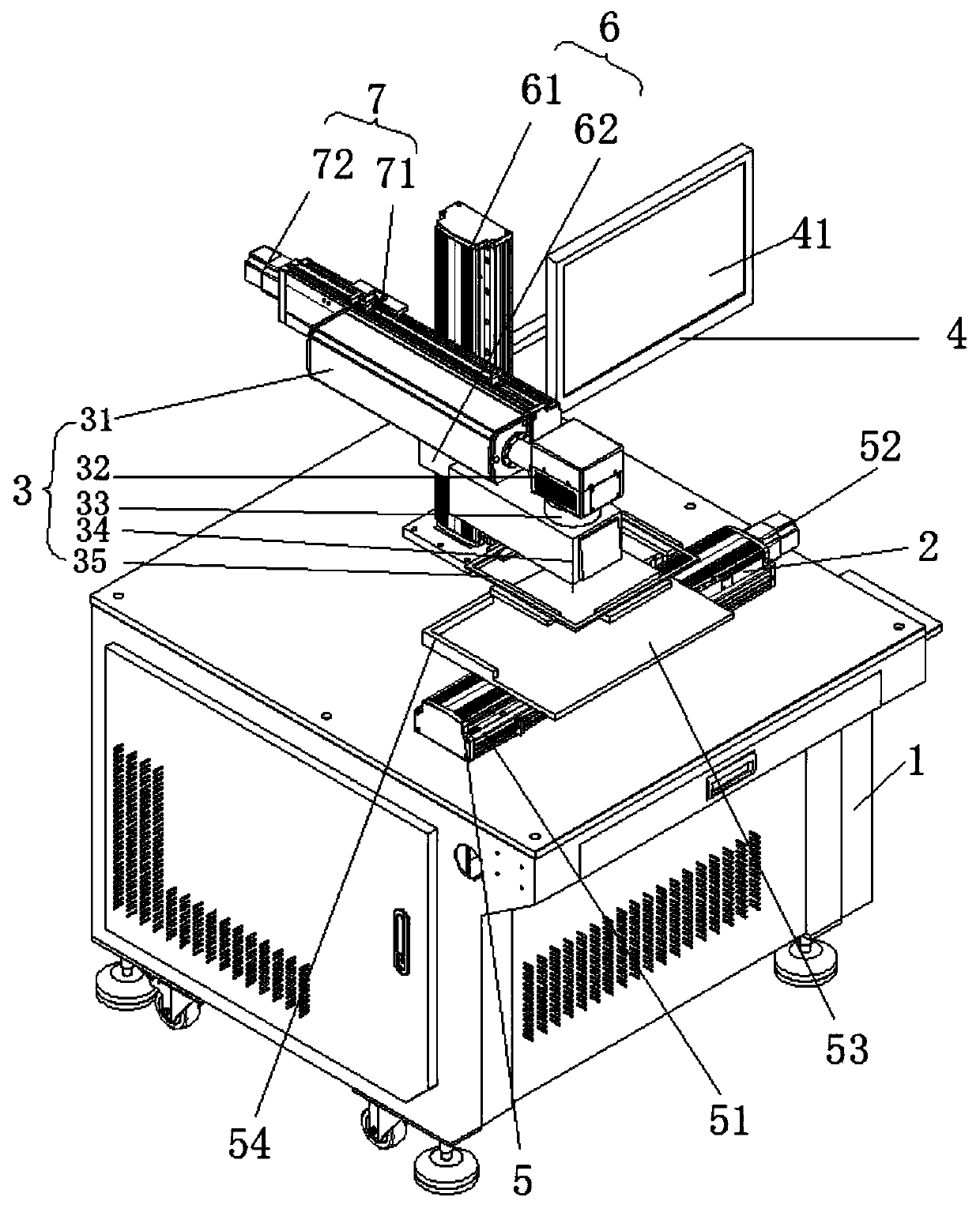

[0034] Such as figure 1 The shown laser marking machine includes a main frame 1, a three-axis motion assembly 2 arranged on the main frame 1, a laser marking assembly 3 fixed on the three-axis motion assembly 2, and a control assembly 4; The moving assembly 2 includes a first transmission assembly 5 arranged on the main frame 1, a lifting assembly 6 located on one side of the first transmission assembly 5, and a second transmission assembly 7 movably installed on the lifting assembly 6; the first transmission assembly 5 It is mainly used for the workpiece disk 53 to move in the left and right directions of the host computer 1 (in this embodiment, the X axis in the coordinate axis), and the second transmission assembly 7 is mainly used to control the movement of the laser marking assembly 3 in the front and rear directions of the host computer 1 ( In this embodiment, it is the Y axis in the coordinate axis); the lifting assembly 6 is mainly used to control the movement of the s...

Embodiment 2

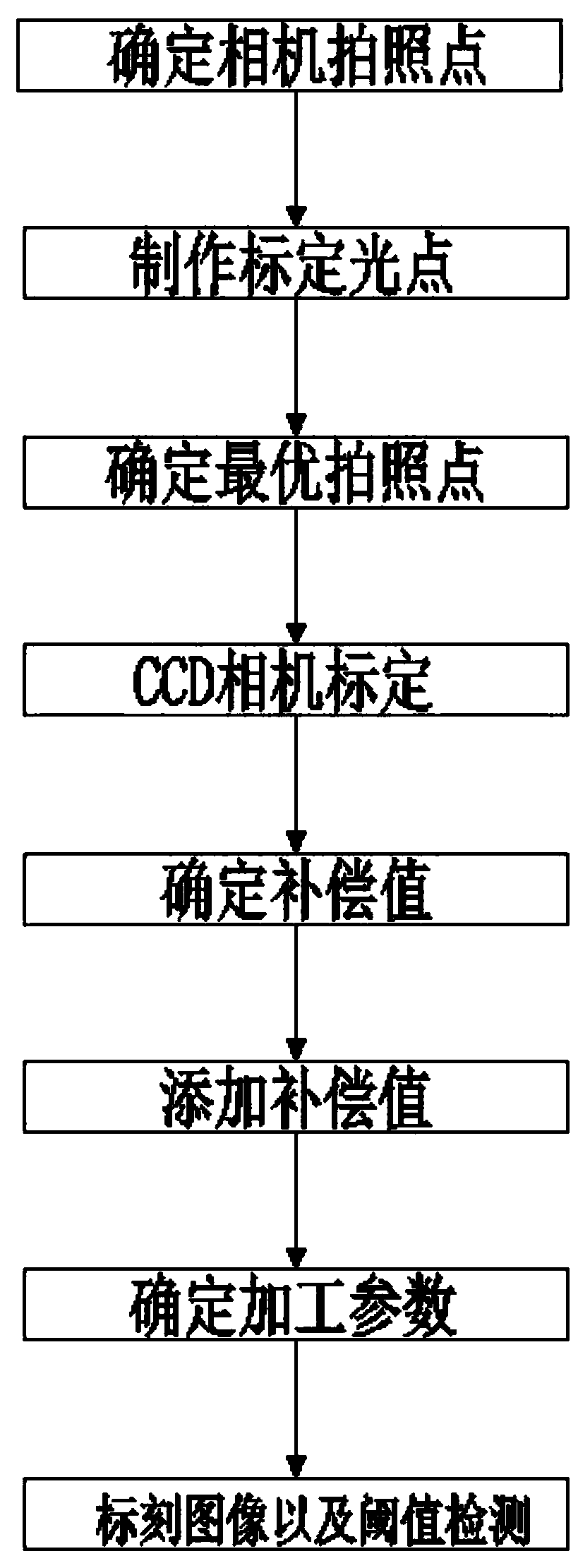

[0046] Such as figure 2 A laser positioning marking method shown includes the following steps:

[0047] Step 1: Determine the photographing point of the camera; turn on the square light source 35, place a blank marking paper on the workpiece tray 53 and align it with the two sides of the right-angle positioning block 54, control the first transmission assembly 5, and move the marking paper to the CCD camera Open the lower end of the industrial computer, open the camera lens, and observe the picture returned by the CCD camera on the touch screen. By adjusting the lifting assembly 6, the field of view of the CCD camera is the same as the size of the marking paper, and on the touch screen 41 Record the height coordinates of the current camera;

[0048] Step 2: Make calibration light spots; turn on the laser generator, and uniformly laser mark 16 groups of light spots on the marking paper by controlling the first transmission component and the second transmission component; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com