Jacking transfer machine

It is a technology of lifting, transferring and jacking, which is applied in the direction of transportation, packaging, roller table, etc., and can solve the problems of unstable center of gravity of loaded items, wear of mechanical parts, and affecting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

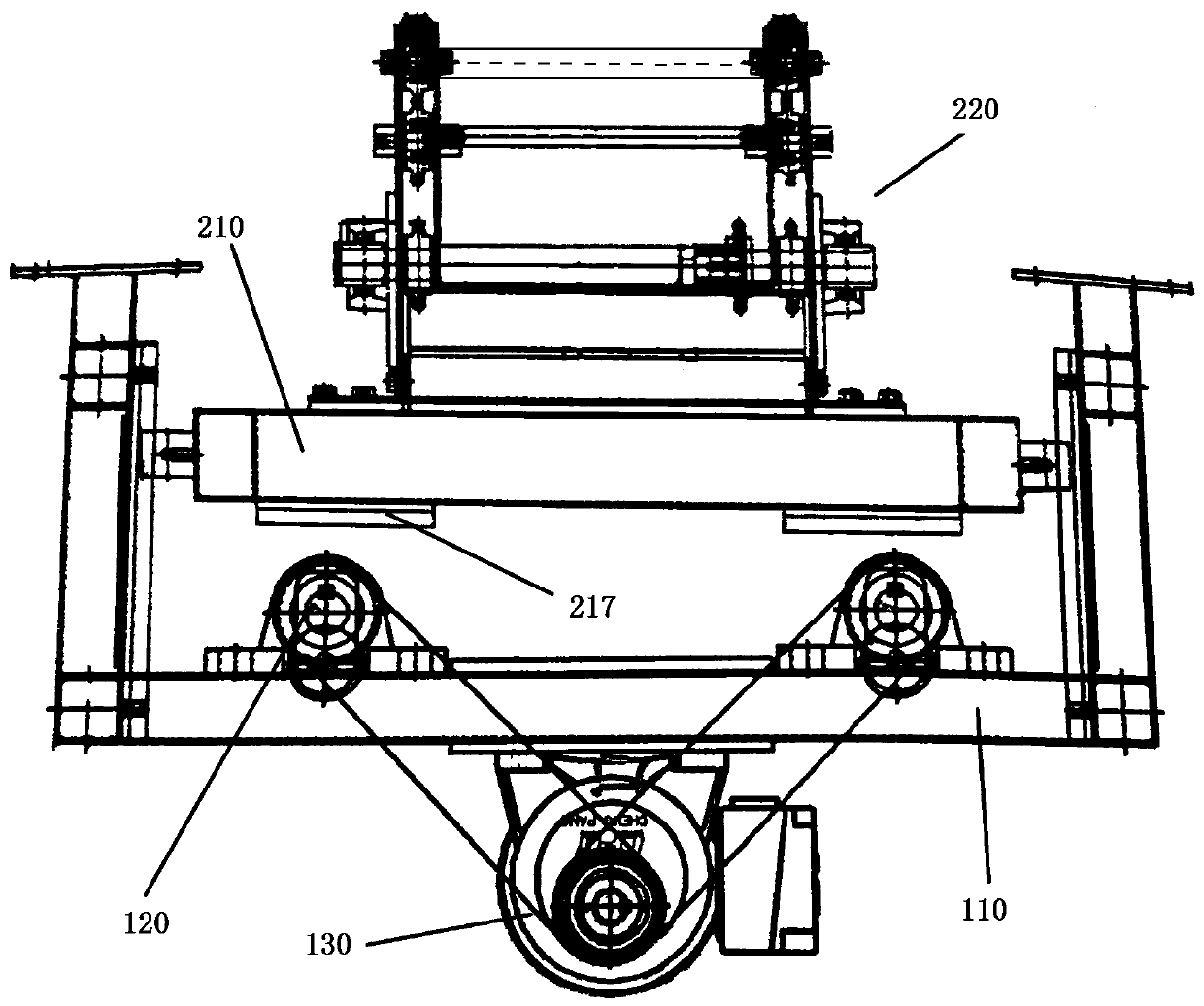

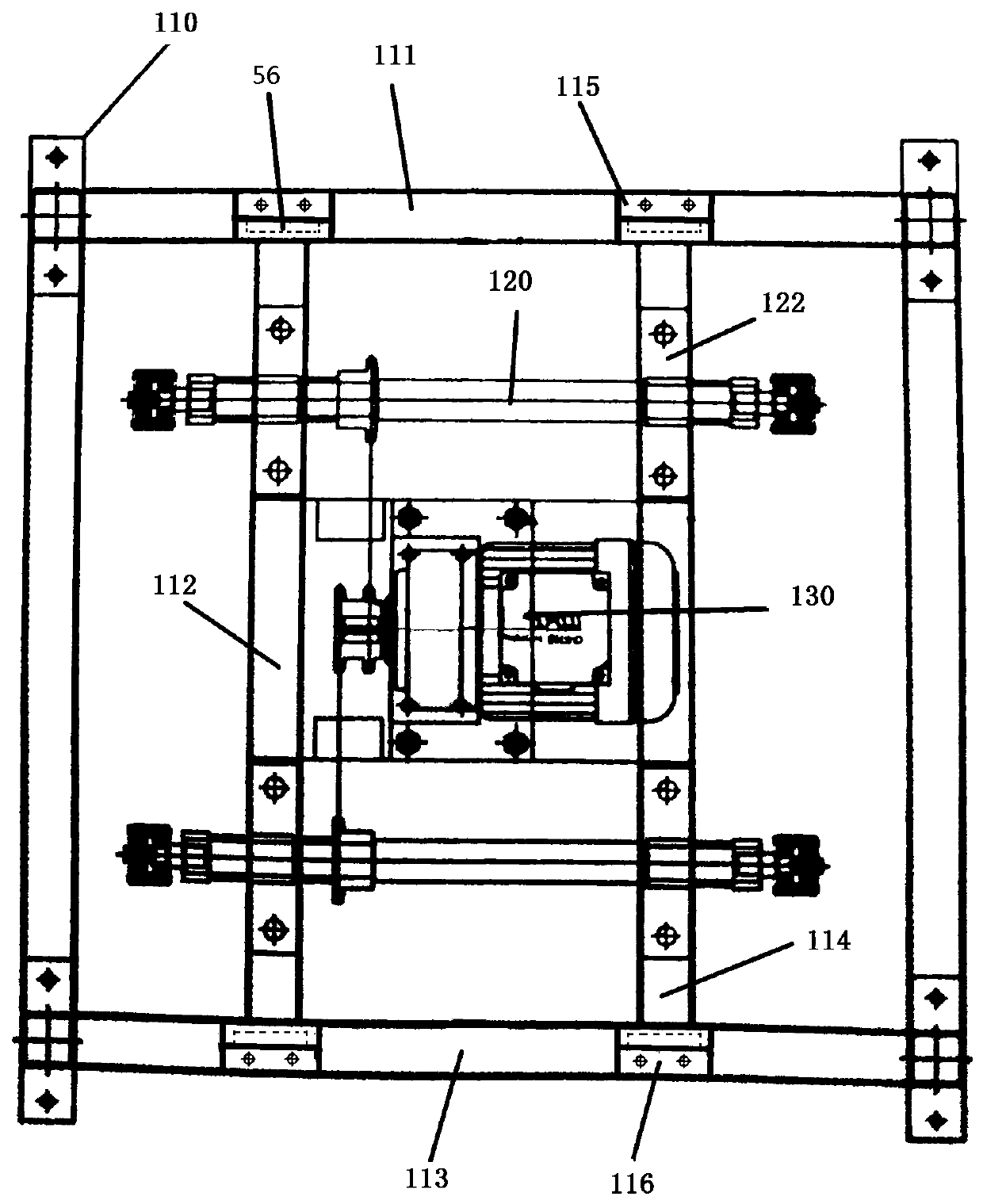

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, this embodiment provides a jacking and transferring machine, including: a jacking device and a transfer device arranged on the jacking device, the jacking device includes a bearing bottom frame 110, and is installed on the bearing The jacking drive assembly 120 on the upper surface of the bottom frame 110 and the jacking motor 130 installed on the lower surface of the bearing bottom frame 110, the jacking motor 130 is transmission connected with the jacking drive assembly 120 through a transmission chain;

[0036]The bottom frame 110 includes a first frame 111, a second frame 112, a third frame 113, and a fourth frame 114 connected end to end in sequence, the first frame 111 is parallel to the third frame 113, and the second frame 111 is parallel to the third frame 113. The frame 112 is parallel to the fourth frame 114, the upper surface of the first frame 111 is provided with a number of leading columns 1...

Embodiment 2

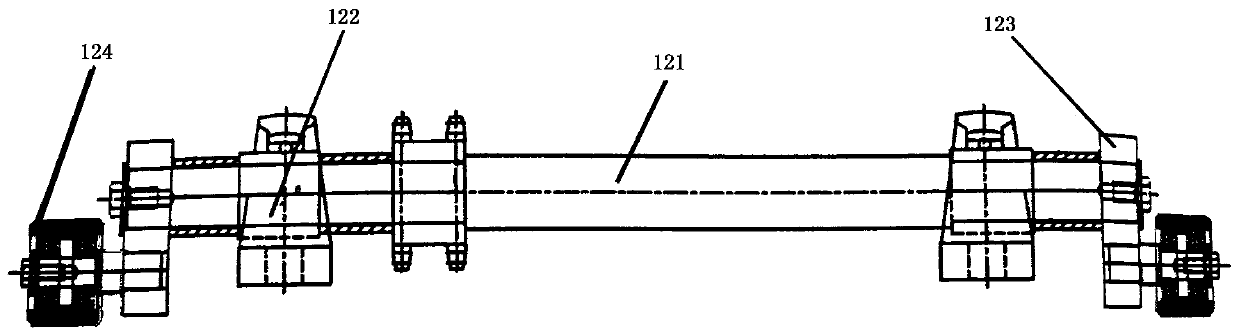

[0042] Such as Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the difference between this embodiment and the previous embodiments is that the limiting plate 217 abuts against the upper part and the outermost surface of the contact bearing 124 respectively. The upper part of the contact bearing 124 can realize the lifting of the transfer device, and the outermost surface of the contact bearing 124 can reduce the movement of the transfer device in the extending direction of the drive shaft 121 .

[0043] The limiting plate 217 is detachably connected to the limiting frame. Due to the formation of wired contact and surface contact, the limiting plate 217 is a consumable item, and being detachable is beneficial to the timely replacement of the limiting plate 217 and improves the jacking stability.

[0044] The accommodating groove 56 of the front guide post 115 and the accommodating groove 56 of the rear guide post 116 are arranged symmetrically, and the accommodating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com