Garbage treating furnace capable of improving controllability of technological parameters

A technology of waste treatment and process parameters, applied in gasification process, coke oven, petroleum industry, etc., can solve the problems of land occupation, flue gas purification treatment and discharge burden, threat of groundwater resources, etc., achieve continuous feeding and improve treatment efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

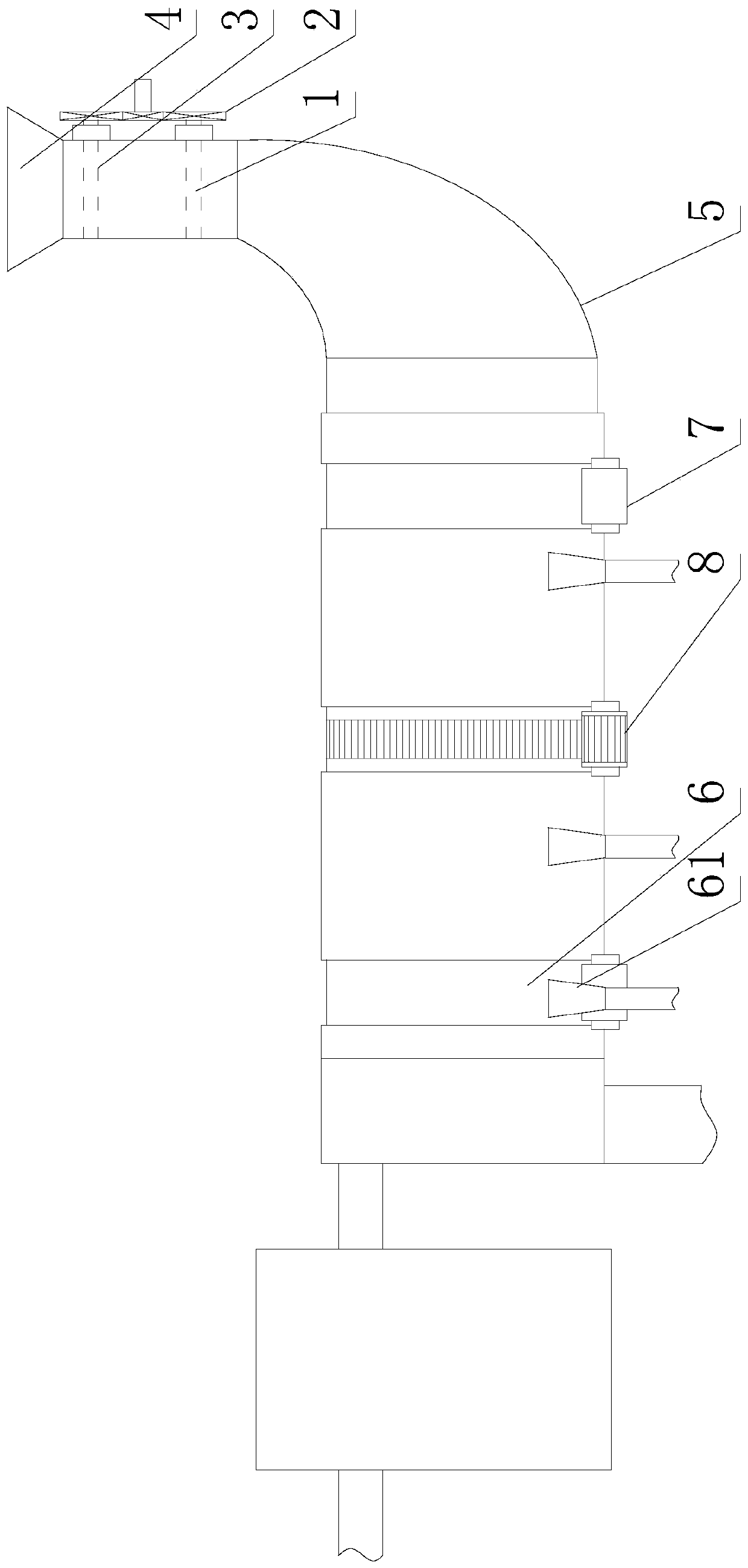

[0039] Such as figure 1 As shown, a garbage treatment furnace that can improve the controllability of process parameters is a pyrolysis furnace or a gasification furnace, and the treatment furnace includes a furnace body 6 for heating garbage, and the furnace body 6 It is in the shape of a cylinder with openings at both ends, and the opening at one end is used as the material feeding end, and the opening at the other end is used as the material discharging end;

[0040] The furnace body 6 is also provided with a material transfer mechanism, and the material transfer mechanism is used to realize the transfer of materials in the furnace body 6: from the feed end to the discharge end;

[0041] It also includes a heating assembly 61 for heating the furnace body 6. There are at least three groups of the heating assembly 61, the furnace body part at the feed end, the furnace body part at the discharge end, the furnace body part at the feed end and the discharge end. The furnace bod...

Embodiment 2

[0046] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, as a specific implementation of the material transfer mechanism, it is set as follows: the material transfer mechanism is a plurality of deflectors installed on the inner wall of the furnace body 6, and the deflectors are rotated by the furnace body 6 to push the material from the The feed end is transferred to the discharge end. With this solution, the furnace body 6 is used to drive the deflector to rotate. During the rotation of the deflector, a plurality of deflectors work together, and the deflectors cooperate to provide a thrust towards the discharge end of the material to realize the transmission. With this scheme, the deflector is a push plate welded on the inner wall of the furnace body 6 to achieve the corresponding purpose. This type of material transfer mechanism does not require additional power parts and transmission parts, so it not only has a simple structure an...

Embodiment 3

[0050] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, the feed end of the furnace body 6 is also connected with a feed pipe 5, and the furnace body 6 can rotate around its own axis independently of the feed pipe 5;

[0051] A first valve plate 1 and a second valve plate 3 are installed on the feed pipe 5, and both the first valve plate 1 and the second valve plate 3 are used to control the conduction state of the feed pipe 5;

[0052] In the extending direction of the feed pipe 5, the first valve plate 1 and the second valve plate 3 are installed in different positions;

[0053] It also includes a linkage device 2, which is used to link the first valve plate 1 and the second valve plate 3, so that during the movement of the first valve plate 1 and the second valve plate 3, either one is in the cut-off position. During the state of feeding pipe 5, the other is in the state of conducting feeding pipe 5. In this solution, it is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com