Large physical modeling experiment device for simulating hydraulic fracturing and casing damage under in-situ condition, and method

A technology of physical models and experimental devices, applied in teaching models, earthwork drilling, wellbore/well components, etc., can solve the problem of limited devices and methods, the inability to use larger-sized rocks, and no method for simulating in-situ conditions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

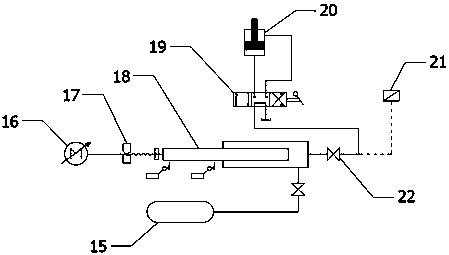

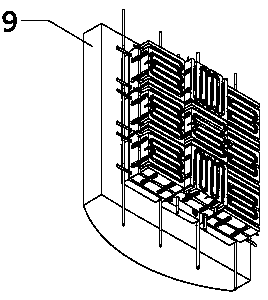

[0050] A large-scale physical model experimental device for simulating well layout and in-situ injection and production, including a physical model body unit, an axial pressure loading unit, a radial pressure loading unit, a high-pressure injection unit, a temperature loading unit, a monitoring unit and a data processing unit:

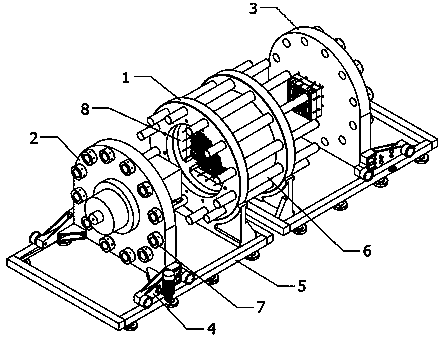

[0051] like figure 1 As shown, the object model body unit includes a base, a kettle body 1, a front cover plate 2, a rear cover plate 3, a cover plate bracket 4 and a guide rail 5, and the kettle body 1 is fixed in the middle of the base, and the kettle body 1 The inside is a cylindrical cavity, and the two sets of guide rails 5 are installed on the base along the axial direction of the kettle body 1 and parallel to each other, and the front cover 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com