Cylindrical bearing of moving part of cabinet air conditioner

A technology for air-conditioning cabinets and moving parts, which is applied to rotating parts, bearings, ball bearings and other directions that resist centrifugal force, can solve problems such as bearing rust failure, enhance anti-rust ability, improve overall accuracy, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

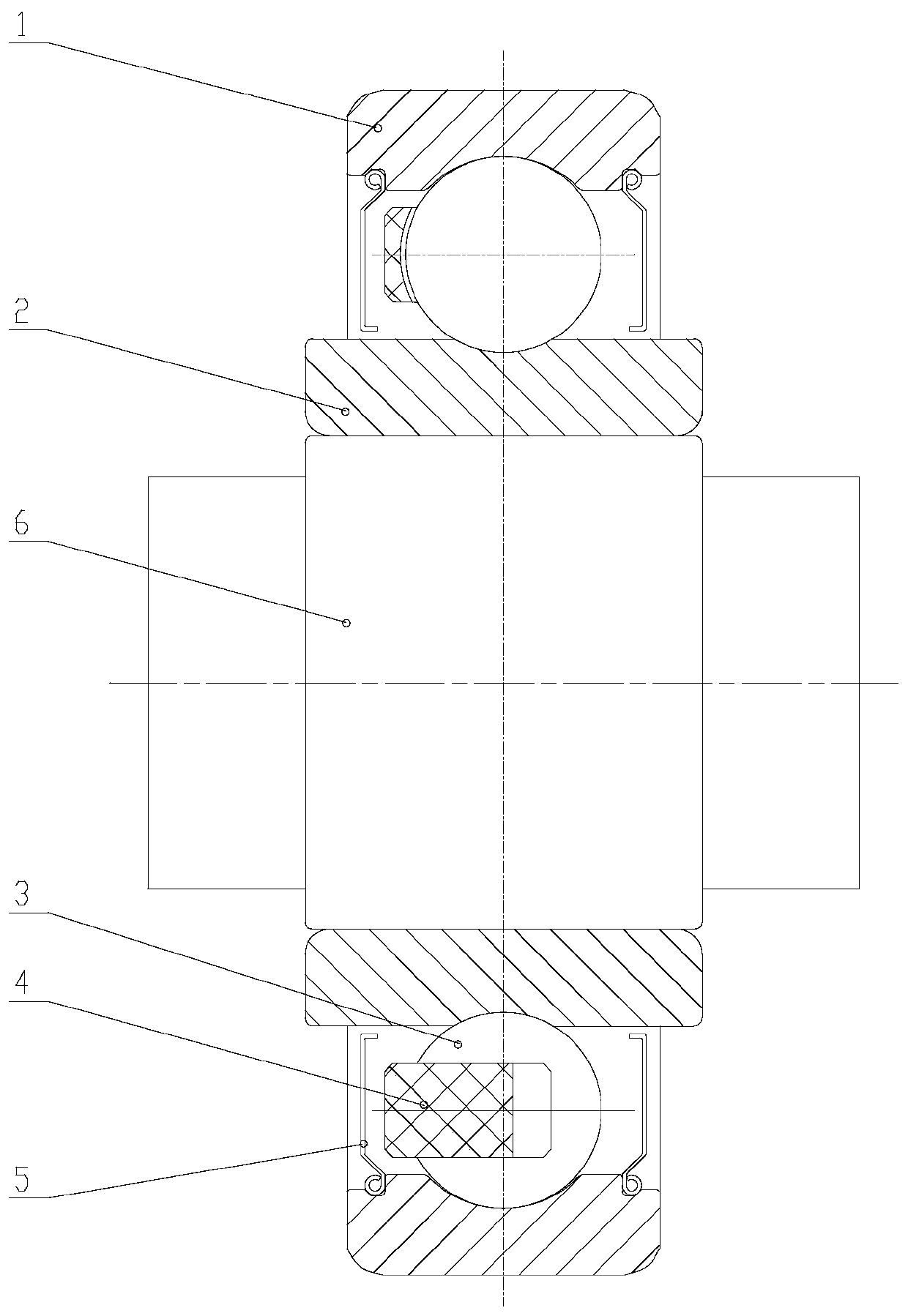

[0016] Such as figure 1 As shown, the present invention relates to a cylindrical air-conditioning cabinet machine moving part bearing, including an outer ring 1, an inner ring 2, rolling elements 3, a cage 4 and a dust cover 5; the cage 4 is evenly provided with rolling elements 3; The dust cover 5 is pressed into the dustproof grooves at both ends of the outer ring 1; the present invention also includes a mandrel 6, the width of the inner ring 2 is greater than the width of the outer ring 1, improving the positioning accuracy of the product; The inner ring 2 is press-fitted into the core shaft 6 to form a whole body, and the inner ring 2 is tightly connected with the core shaft 6, and the core shaft 6 is a stepped shaft. Pressing the mandrel 6 reduces the customer's assembly error, avoids assembly instability, and improves the overall accuracy of the product.

[0017] The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com