Small kiln cooling device and cooling process thereof

A technology of cooling device and small kiln, applied in furnace cooling, furnace, lighting and heating equipment, etc., can solve the problems of heavy dust removal equipment load, low coke quality, uneven coke cooling, etc. The effect of coke quality and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

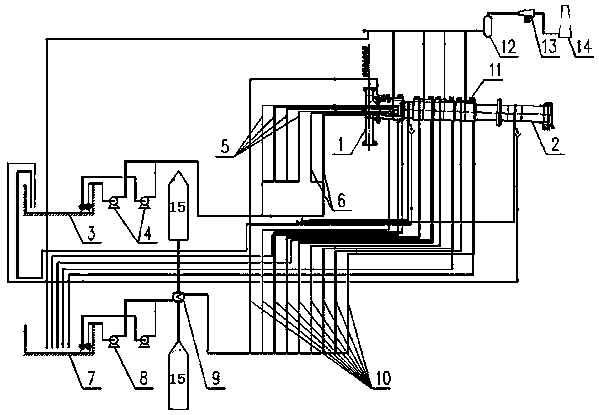

[0015] Such as figure 1 Shown: a cooling device for a small kiln, which includes a small kiln 2, an inner spray water pit 3, an inner water spray pump 4, branch water pipes, an outer water spray pit 7, an outer water spray pump 8, and a heat exchanger 9. Nine water pipes 10 connected to the small kiln shell, small kiln shell 11, mist catcher 12, fan 13 and chimney 14;

[0016] The internal spray water pit is connected to the internal water spray pump, and the internal water spray pump is connected to the tail of the small kiln through branch water pipes;

[0017] The external spraying water pit is connected with the pump for external spraying, and the heat exchanger is respectively connected with the pump for external spraying, the circulating water station 15 and the water pipe connected to the shell of the small kiln, and the shell of the small kiln is connected with the mist catcher, fan and chimney in turn .

[0018] The branch water pipes include four water pipes 5 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com