Heat exchange device based on vibration enhanced heat exchange and heat exchange device set

A heat exchange device and heat exchange enhancement technology, applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as pipeline fatigue damage, increase heat transfer coefficient, and enhance heat exchange effect , Improve the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

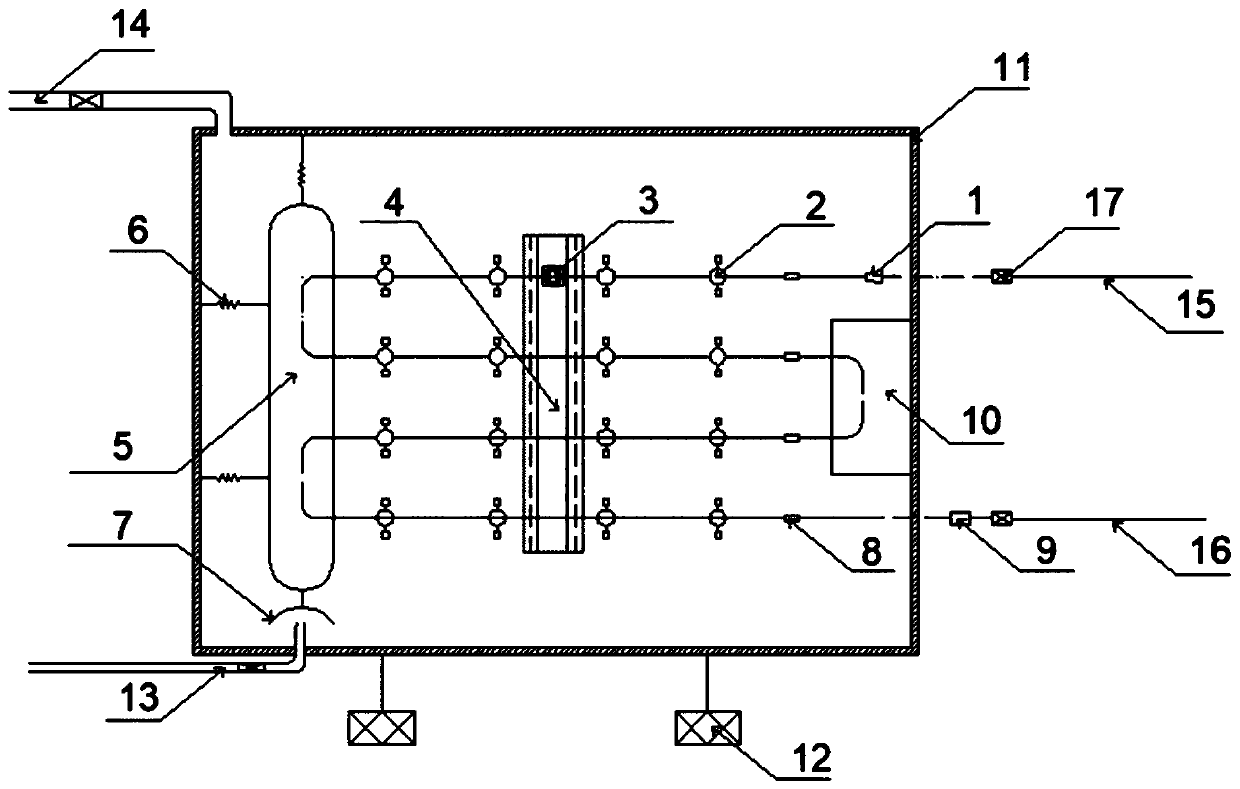

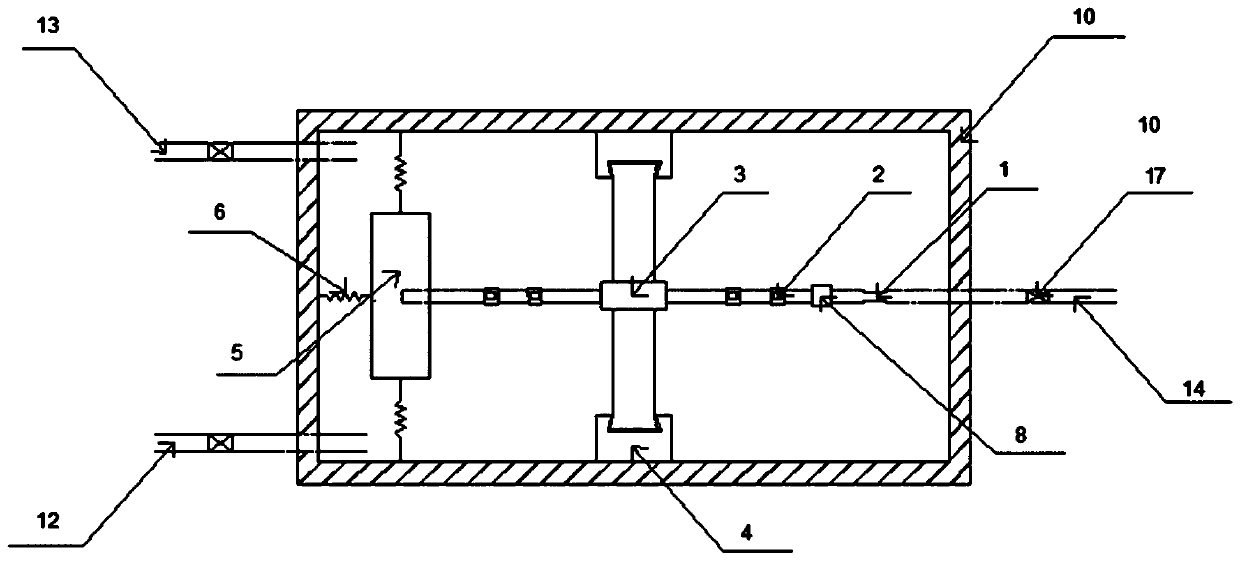

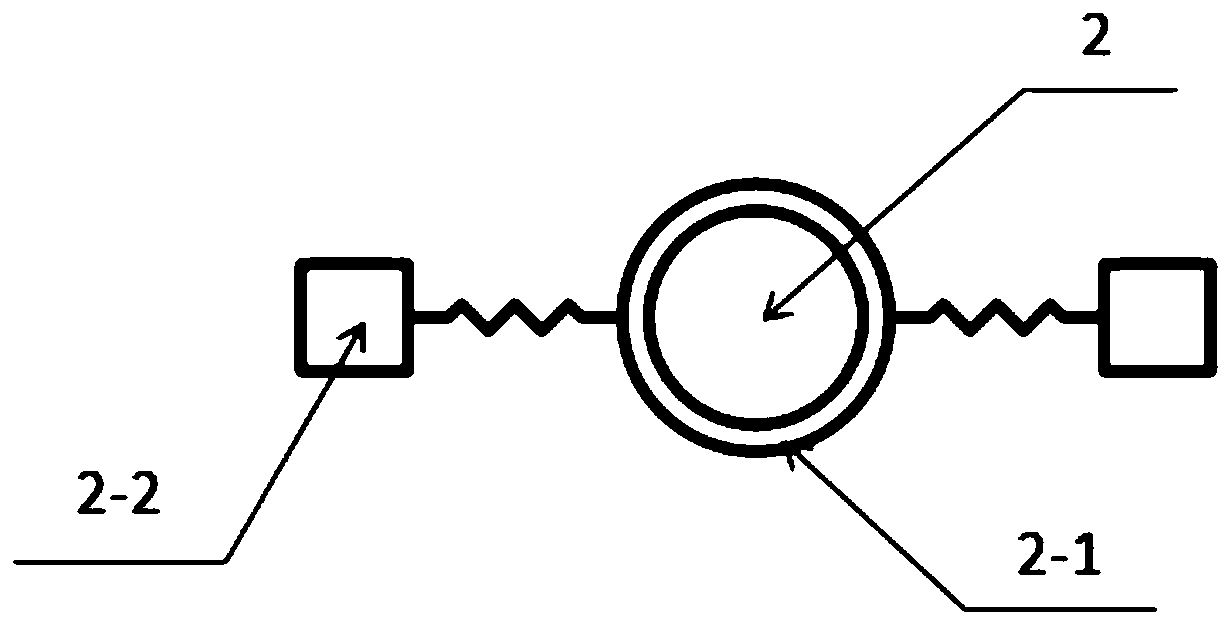

[0042] Such as Figure 1-7 As shown, it is a heat exchange device based on vibration-enhanced heat exchange according to an embodiment of the present invention, including a box body 11 and pipes, wherein the bottom of the box body 11 is provided with a cold water pipe inlet port 13, and the top is provided with a cold water pipe outlet port 14. The upper part of the right side wall of the box body 11 is provided with a hot water pipe inlet port 15, and the lower part of the right side wall is provided with a hot water pipe outlet port 16. The inner left wall of the box body 11 is connected with a floating mass 5 through a spring 6, and the inner right side wall is connected with a floating mass 5. A fixed block 10 is arranged in the center of the wall surface, and a slideway 4 with a dovetail-shaped groove is arranged symmetrically and vertically on the inner front and rear walls, and a displacement constraint block 3 matched with it is arranged in the slideway 4; The inlet en...

Embodiment 2

[0051] Such as Figure 8 As shown, it is a heat exchange device group based on vibration-enhanced heat exchange according to an embodiment of the present invention, which is composed of N+1 heat exchange devices described in any one of claims 1-8 in series, where N≥1, Respectively, the first-stage heat exchange device, the second-stage heat exchange device, ..., the Nth-stage heat exchange device, the outlet end 16 of the hot water pipe of the first-stage heat exchange device is connected to the second-stage heat exchange device through a pipeline The inlet end 15 of the hot water pipe, and so on, the inlet end 13 of the cold water pipe and the outlet end 14 of the cold water pipe of the heat exchange devices at all levels are respectively connected in parallel to ensure that the cooling medium in the heat exchanger has a lower temperature, which can realize heat transfer. The temperature of the hot water in the water pipeline is lowered several times until it meets the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com