Piston-type volumetric fluid metering device and metering method

A metering device and volumetric technology, applied in volume change compensation/correction devices, shrinkage/expansion chambers, etc., can solve problems such as large errors in manual chi-square measurement methods, large safety and environmental hazards, and large manpower and material resources. Avoid manpower and material resources, reduce maintenance costs, and have high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

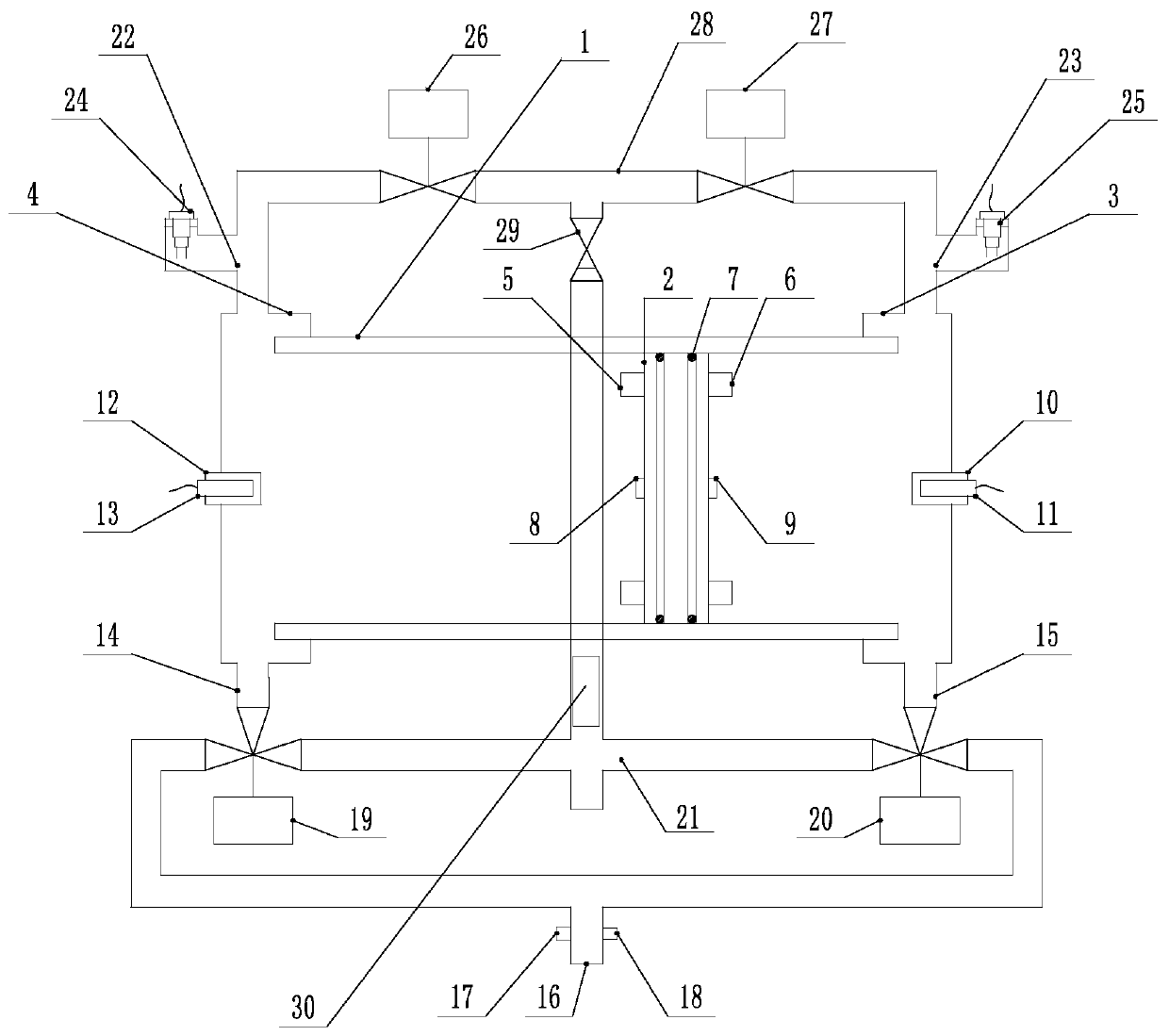

[0028] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a piston-type volumetric fluid metering device described in this embodiment includes a cylinder body 1, a piston 2, a No. 1 cylinder head 3, a No. 2 cylinder head 4, a No. Positioning part 6, seal 7, No. 1 triggering part 8, No. 2 triggering part 9, No. 1 in-position detection part 11, No. 2 in-position detection part 13, No. 1 infusion tube 14, No. 2 infusion tube 15, incoming liquid tube 16 , No. 1 three-way valve 19, No. 2 three-way valve 20, liquid outlet pipe 21, No. 1 air pipe 22, No. 2 air pipe 23, No. 1 liquid level sensor 24, No. 2 liquid level sensor 25, No. 1 two-way Valve 26, No. 2 two-way valve 27, exhaust pipe 28, one-way valve 29 and control center 30;

[0029] The two ends of the cylinder body 1 are respectively provided with a No. 1 cylinder head 3 and a No. 2 cylinder head 4. The center of the No. 1 cylinder head 3 is provided with a No. 1 in-position detection component...

specific Embodiment approach 2

[0033] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment is a further limitation of the metering device described in the first embodiment, a piston type volumetric fluid metering device described in this embodiment, the No. 2 in-position detection component 13 described The casing is covered with a No. 2 protective casing 12;

[0034] In this specific embodiment, the No. 2 in-position detection component 13 is used with a No. 2 protective case 12 on the outer shell, in order to protect the No. 2 in-position detection component 13 and has a waterproof function.

specific Embodiment approach 3

[0035] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is a further limitation on the metering device described in Embodiment 1. In this embodiment, a piston-type volumetric fluid metering device, the No. 1 in-position detection component 11 described There is a No. 1 protective case 10 on the casing;

[0036] In this specific embodiment, the No. 1 in-position detection component 11 is covered with a No. 1 protective case 10 , in order to protect the No. 1 in-position detection component 11 , and has a waterproof function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com