High-temperature pressure sensor chip based on MEMS process

A pressure sensor and chip technology, applied in the measurement of the elastic deformation force of the measurement gauge, the measurement of the property force of the applied piezoelectric resistance material, etc., can solve the problems of piezoresistive element and metal layer connection failure, metal fracture, etc. Achieve good high temperature resistance and stability, not easy to oxidize, and avoid oxidation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can fully understand and realize the present invention.

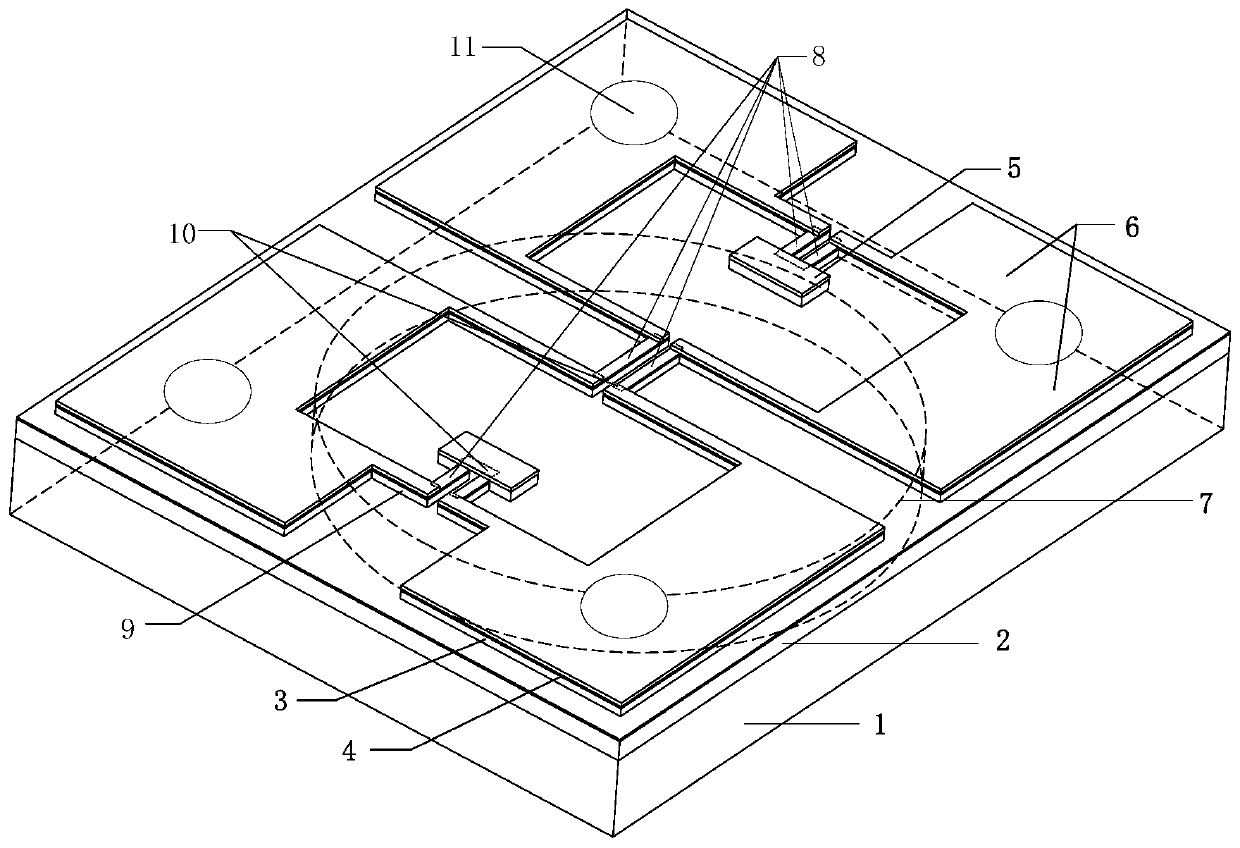

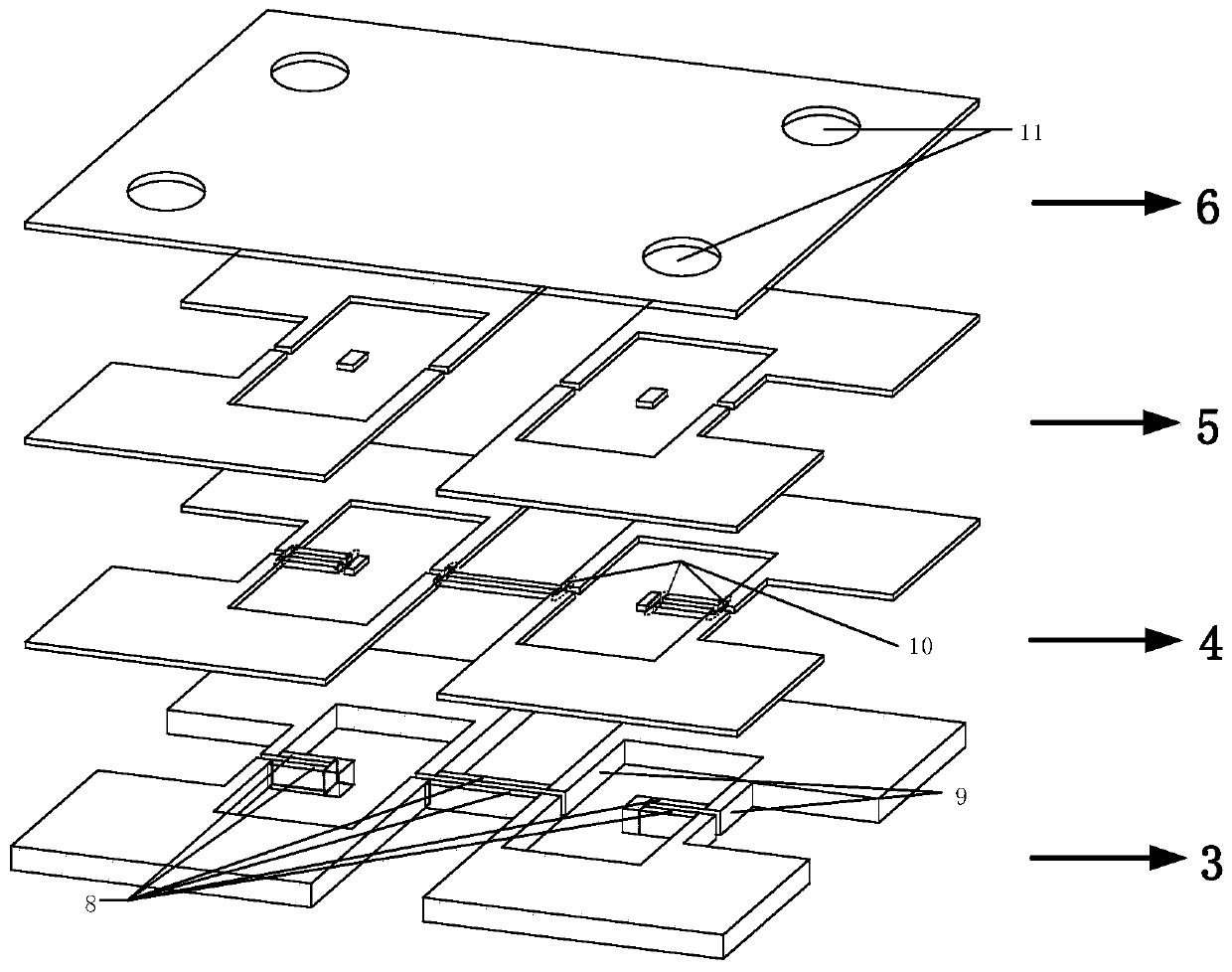

[0018] figure 1 It is a structural schematic diagram of a MEMS-based high-temperature pressure sensor chip involved in the present invention. The high-temperature pressure sensor chip includes a chip base 1, a P-type epitaxial layer 2, an N-type epitaxial layer 3, a piezoresistive element isolation layer 4, a metal layer 5, and a pressure-sensitive film 7; the N-type epitaxial layer 3 includes a piezoresistive The element 8 and the connecting bracket 9 have the same thickness; the piezoresistive element isolation layer 4 covers the piezoresistive element 8 and the connecting bracket 9, and the position corresponding to the piezoresistive element 8 is etched on the piezoresistive element isolation layer There is an ohmic contact window 10; the metal layer and the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com