A cuprous oxide/cuprous thiocyanate heterojunction photoelectric thin film and its preparation method

A technology of cuprous thiocyanate and photoelectric thin film, which is applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problem of high recombination rate of photogenerated carriers, achieve low cost, easy regulation, and improve the effect of photoelectrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

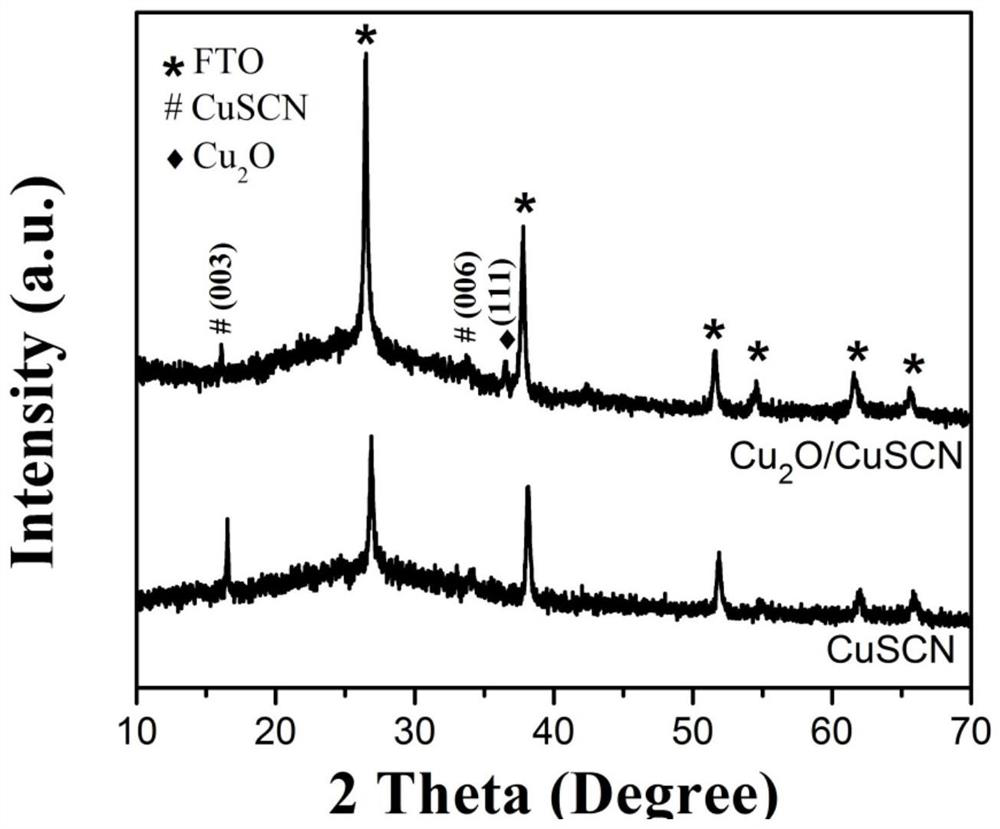

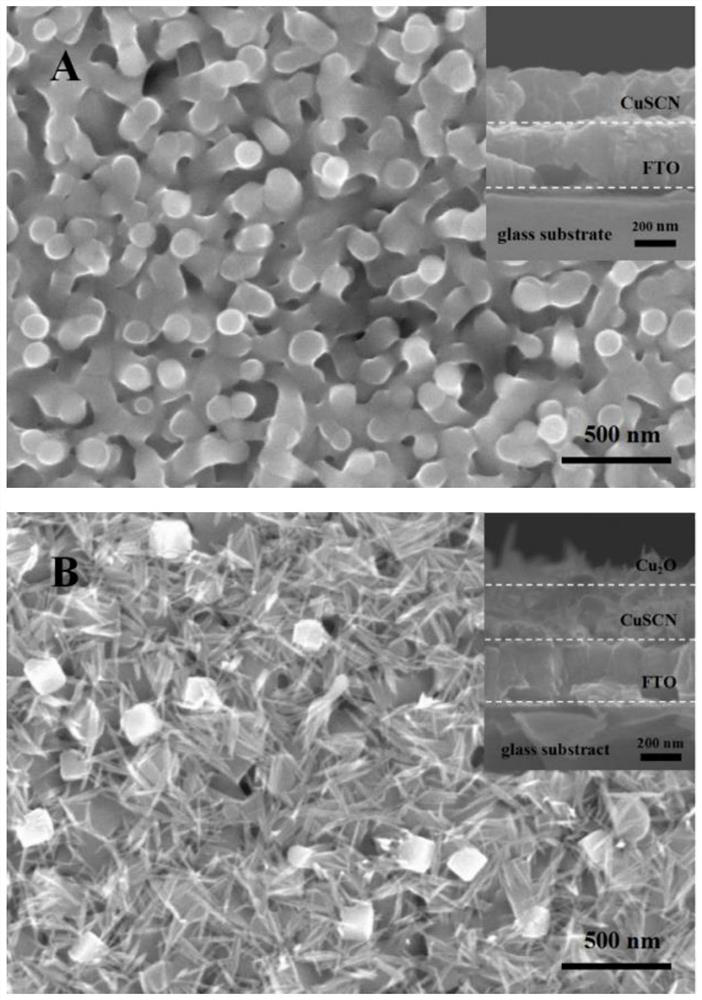

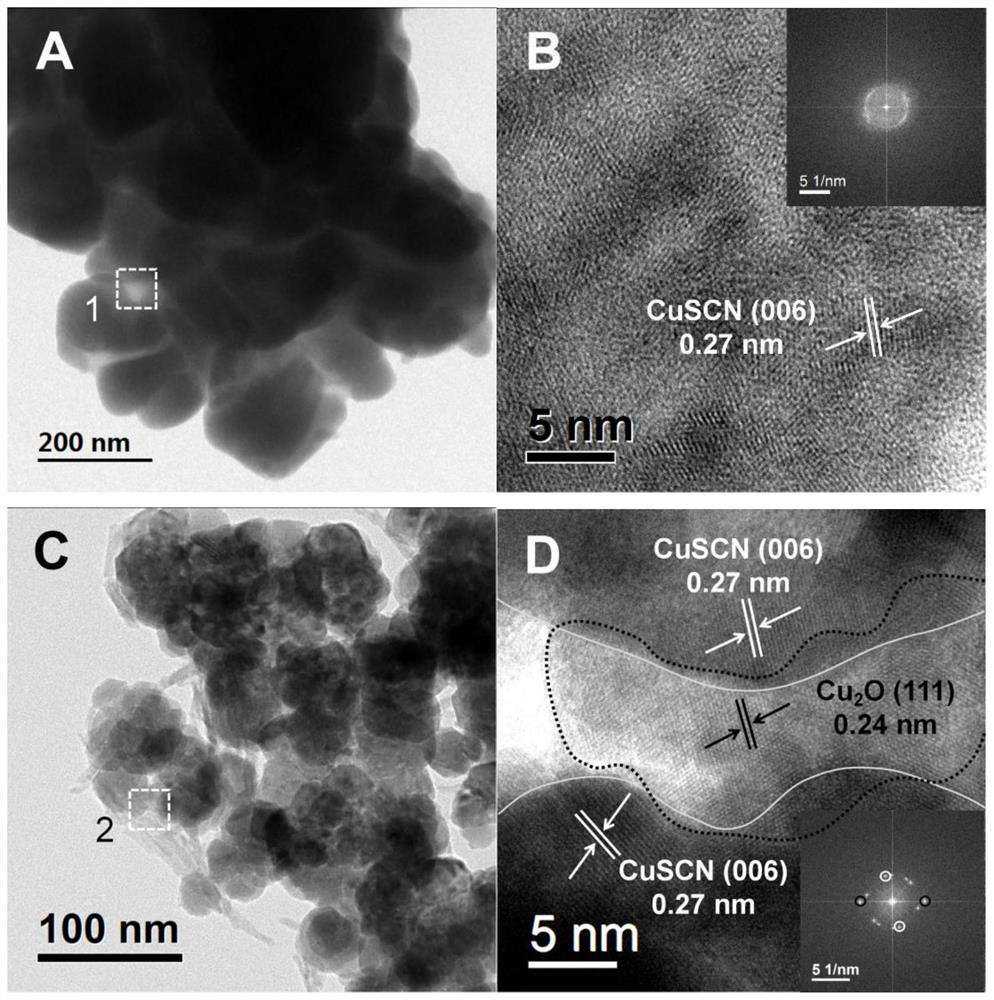

[0018] (1) Dissolve 2.4 mmol of copper sulfate pentahydrate, 2.4 mmol of ethylenediaminetetraacetic acid (EDTA) and 0.6 mmol of potassium thiocyanate (KSCN) in 200 mL of deionized water successively, stir well and prepare the precursor solution; the precursor solution prepared above was transferred to a three-electrode system electrochemical reaction tank equipped with a platinum wire counter electrode (platinum wire), a calomel reference electrode and a cleaned FTO conductive glass, at a deposition potential of -0.4 V, deposited charge is 80 mC / cm 2 Electrochemical deposition was carried out under the conditions; the FTO conductive glass after the electrochemical deposition was rinsed twice with deionized water, 60 o After drying in a vacuum oven, CuSCN photoelectric thin films were prepared.

[0019] (2) Soak the CuSCN film prepared above in 0.05 mol / L NaOH solution for 90 s, take it out and rinse it twice with deionized water to obtain the CuSCN film grown in situ 2 O / CuS...

Embodiment 2

[0021] (1) The preparation process of the CuSCN photoelectric thin film is the same as in Example 1.

[0022] (2) On the premise of obtaining the above-mentioned CuSCN photoelectric thin film, soak the CuSCN thin film in 0.05 mol / L NaOH solution for 30 s, take it out and rinse it twice with deionized water, and then the CuSCN film grown in situ can be obtained. 2 O / CuSCN heterojunction photoelectric thin film.

Embodiment 3

[0024] (1) The preparation process of the CuSCN photoelectric thin film is the same as in Example 1.

[0025] (2) On the premise of obtaining the above-mentioned CuSCN photoelectric thin film, soak the CuSCN thin film in 0.05 mol / L NaOH solution for 180 s, take it out and rinse it twice with deionized water to obtain the in-situ grown Cu 2 O / CuSCN heterojunction photoelectric thin film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com