Dust suppression spraying device for railway coal transportation

The technology of spraying device and water spraying device is applied in the direction of spraying device, spraying device with movable outlet, liquid spraying device, etc., which can solve the problem that the uniformity of coal spraying of the whole vehicle cannot be guaranteed, the sprayed water is not atomized, and the cost of construction is high. problems, to achieve the effect of preventing uneven spraying, preventing pollution along the road, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] as attached figure 1 to attach Figure 5 shown

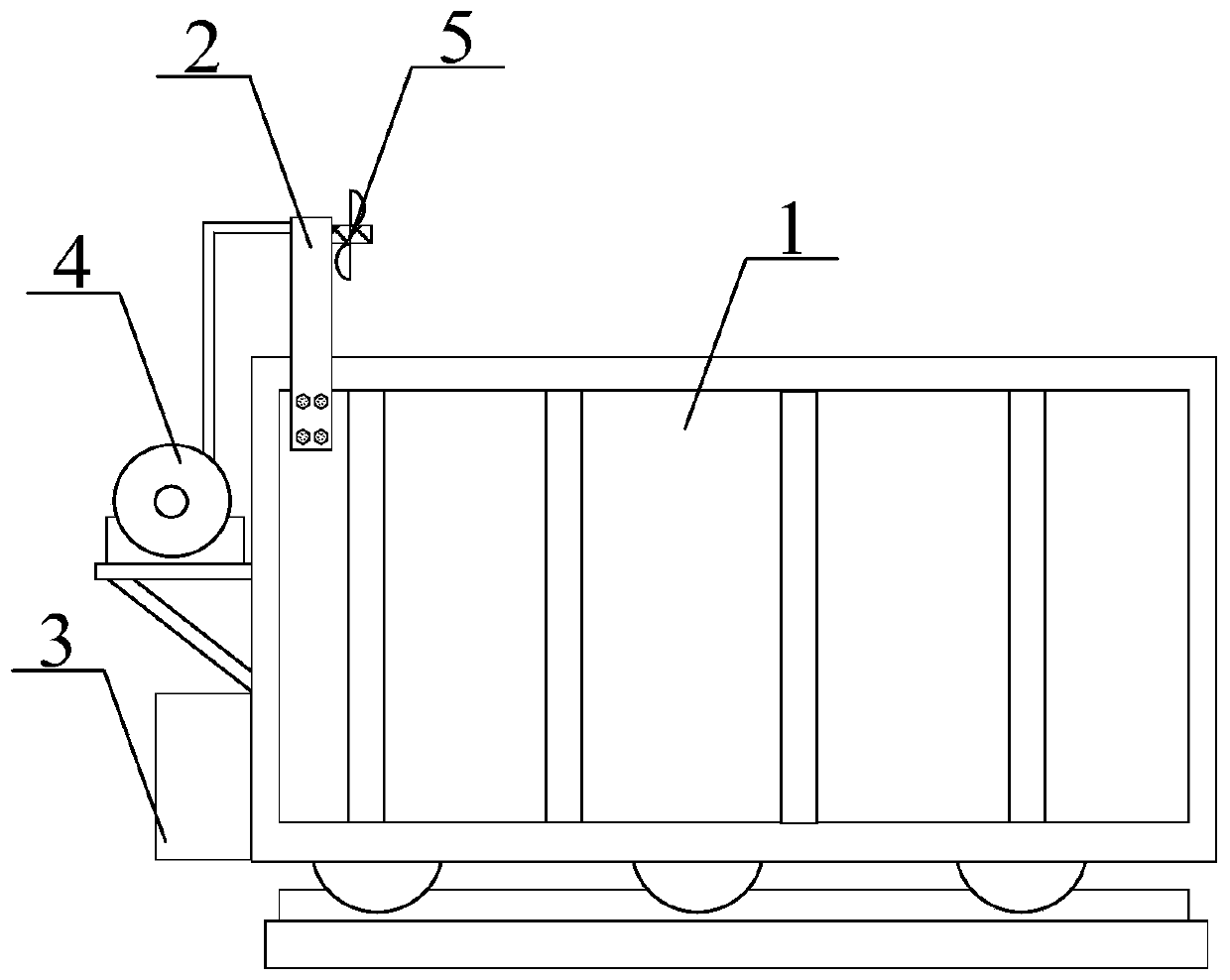

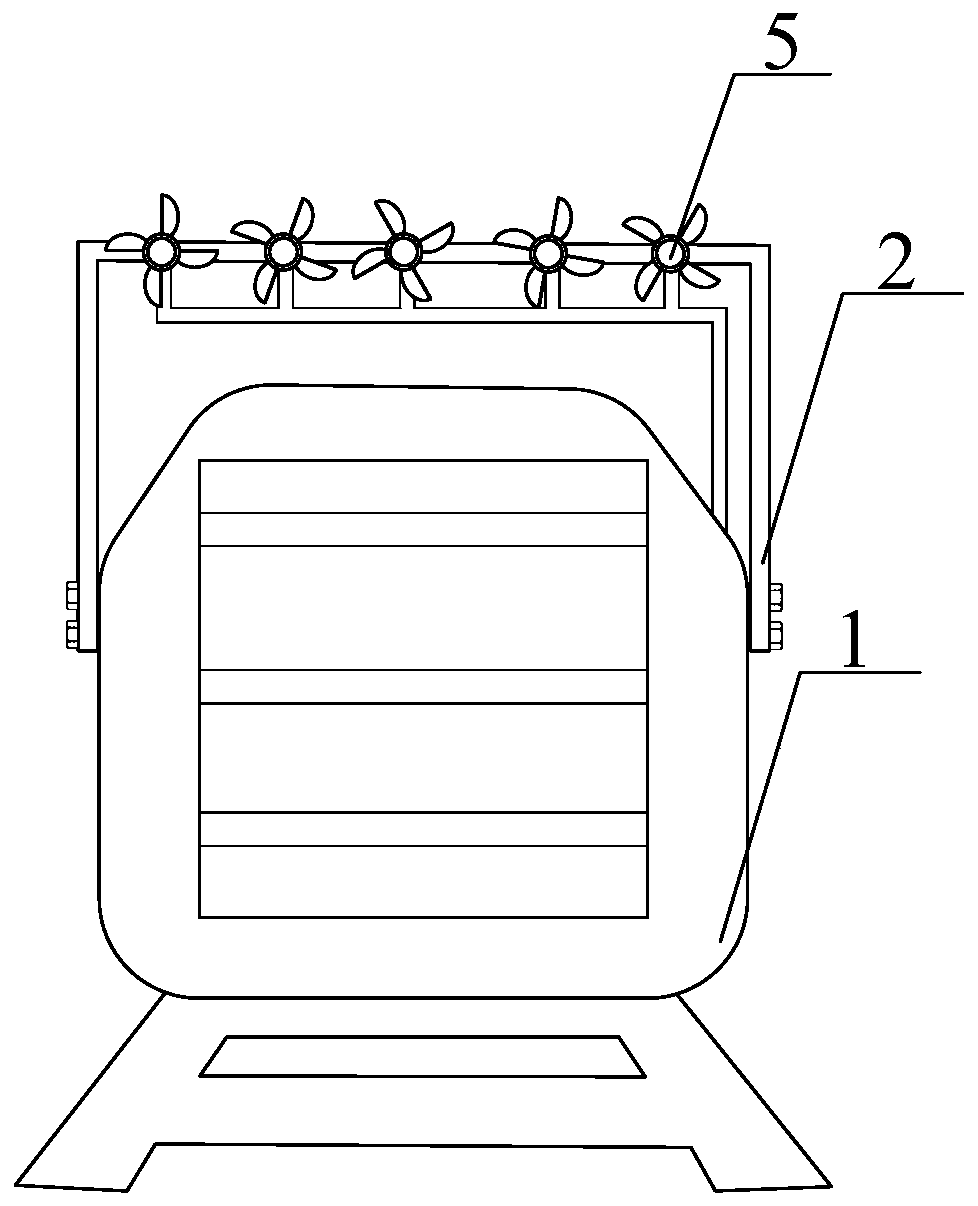

[0025] see Figure 1-5 , a dust suppression spraying device for railway coal transportation, comprising a train carriage 1, a mounting frame beam 2, a control cabinet 3, a water spray device 4 and an atomizing mechanism 5, the mounting frame beam 2 is set in an n-shape, and is connected across the train carriage 1, and fixed by bolts; the control cabinet 3 is installed on one end of the train compartment 1 by bolts;

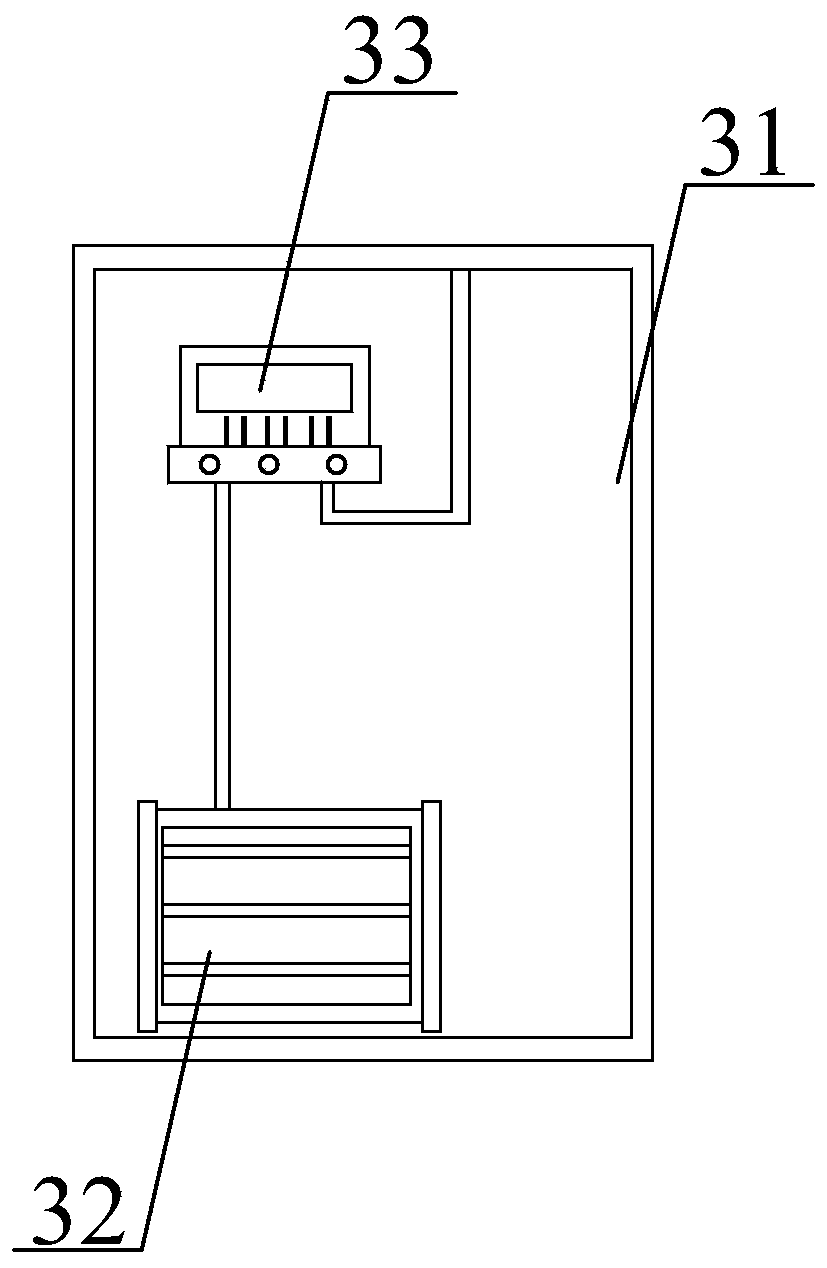

[0026] The control cabinet 3 includes a cabinet body 31, a storage battery 32 and a timer 33, and the cabinet body 31 is bolted to one end of the train compartment 1; the storage battery 32 and the timer 33 are all arranged inside the cabinet body 31; the timer 33 is specifically KG316T type, And be connected with storage battery 32 by wire, storage battery 32 provides suitable power supply for sprinkler 4, can be convenient to control opening and closing of sprinkler 4 by timer 33, and control principle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com