Chip detection and packaging production system

A production system and chip detection technology, applied in the field of chip manufacturing, can solve the problems of low detection efficiency, difficult to control and control abnormal quality factors, and leakage, and achieve the effect of stable chip quality, reasonable design and reduced investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

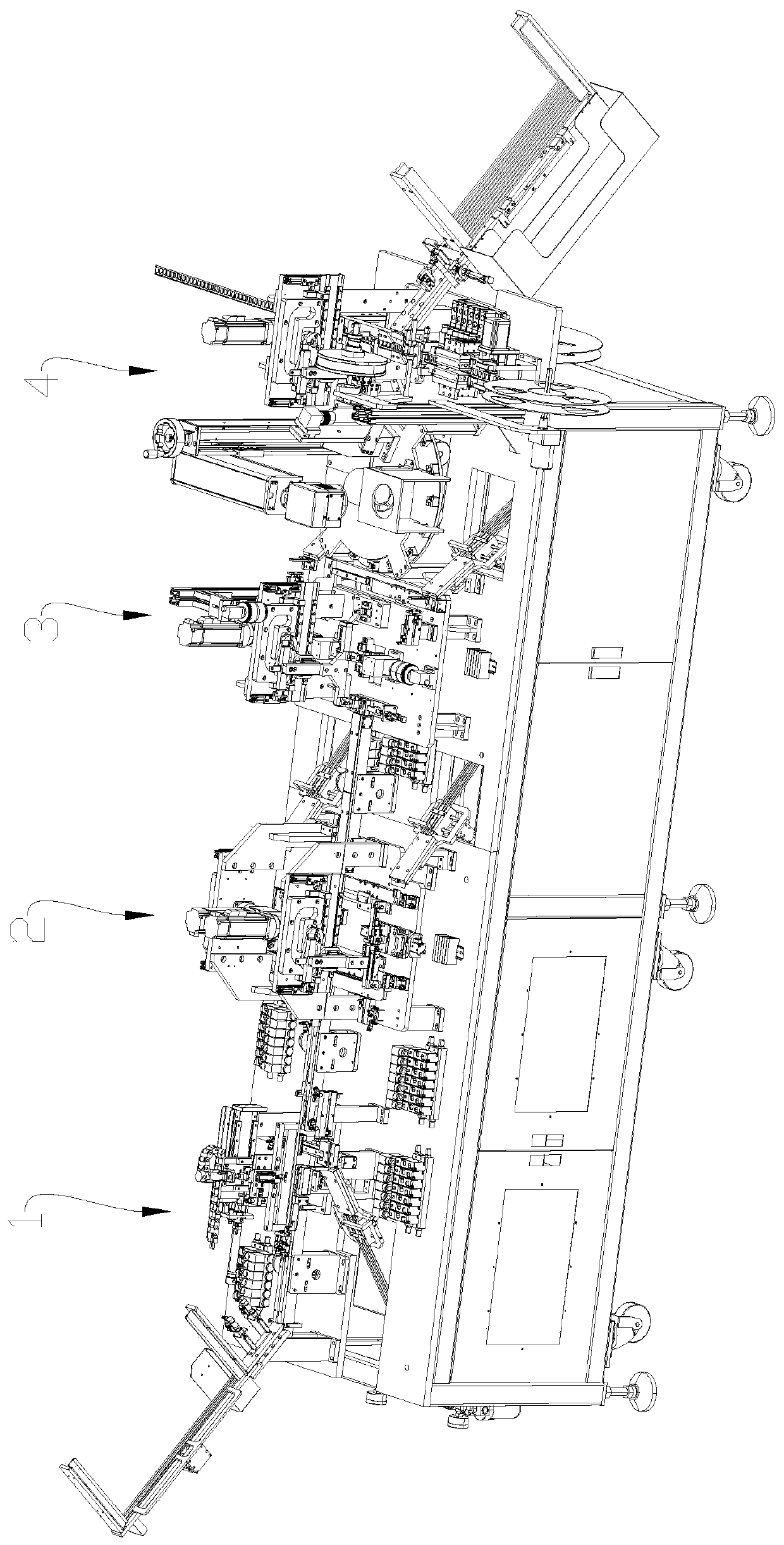

[0029] Such as figure 1 As shown, the present embodiment provides a production system for chip detection and packaging, including a voltage withstand test device 1 for carrying out withstand voltage detection of chips installed on a working platform in sequence, and an electrical test device for carrying out electrical testing of chips. 2, a chip pin foot detection device 3 for testing the flatness, spacing and width of the chip pin feet, and an integrated device 4 for printing and packaging the chip; the first output of the withstand voltage test device 1 The material conveyor belt 16 is connected to the feeding mechanism 221 of the first feeding component 22 of the electrical testing device 2, and the good product transfer mechanism 24 of the electrical testing device 2 is connected to the second feeding component 32 of the chip pin detection device 3, and the chip pin The material transport mechanism 351 of the second defective product collection assembly 35 of the foot det...

Embodiment 2

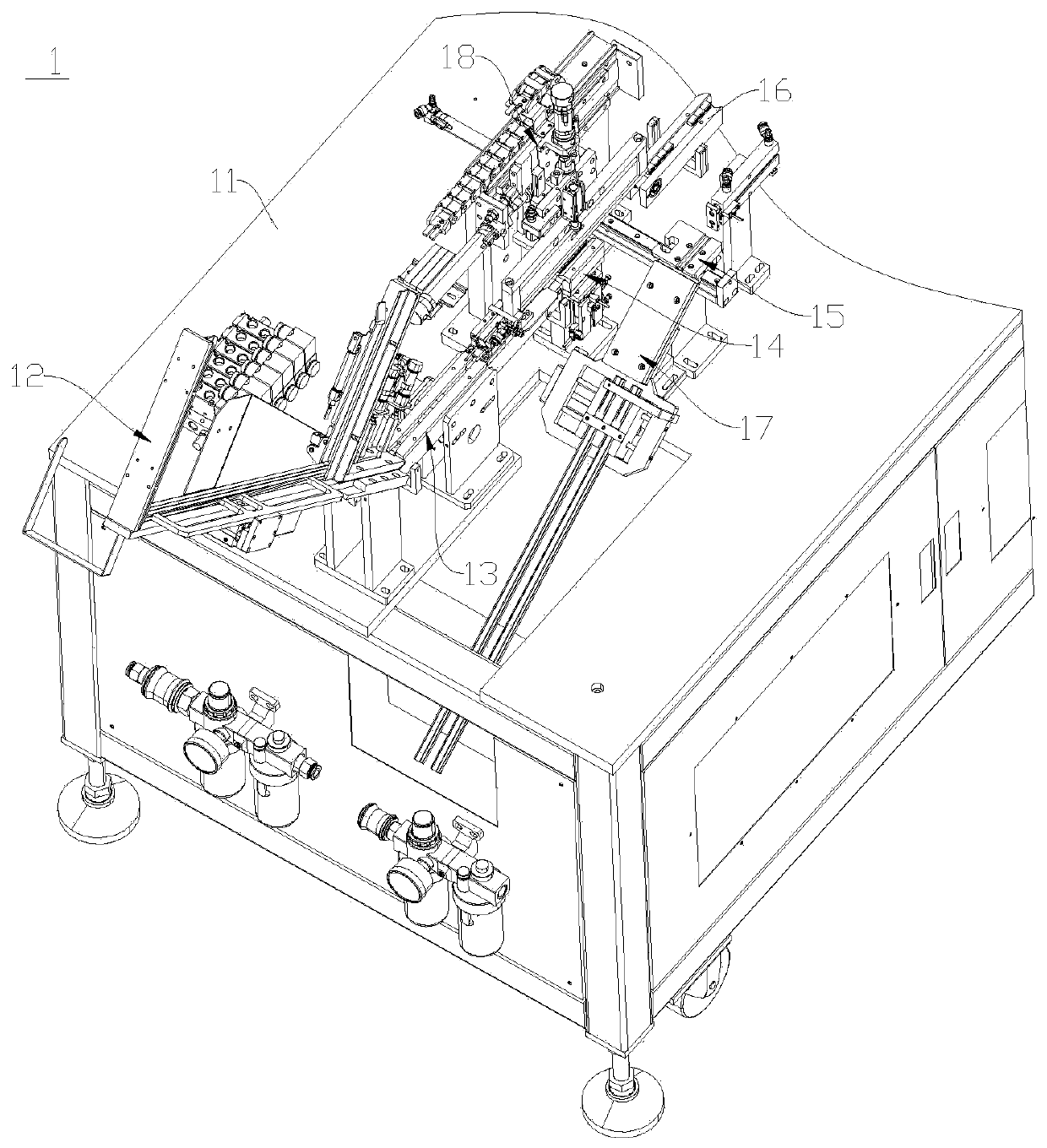

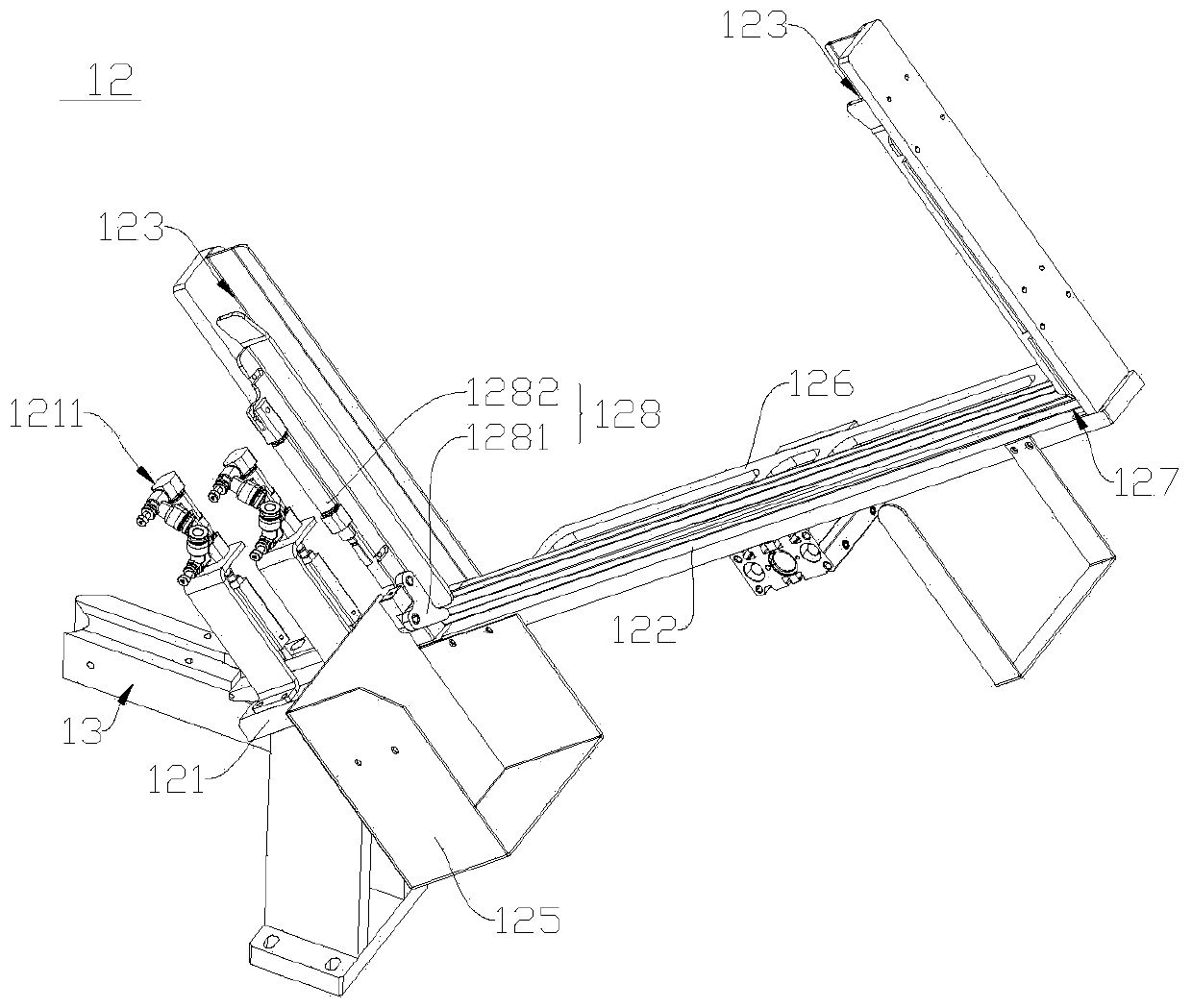

[0031] This embodiment includes all the contents of Embodiment 1, the difference is, as figure 2 As shown, the withstand voltage test device 1 in this embodiment includes a first frame 11 and a blanking mechanism assembly 12 that is sequentially installed on the first frame 11 for blanking, and is used to communicate with the blanking mechanism assembly 12 and transport The feed conveyor belt 13 of the chip, the test fixture 14 for testing the pressure resistance of the chip, the screening mechanism 15 for screening good products and defective products, the first discharge conveyor belt 16 for transporting good products, and the A frame 11 is used to collect the first defective product collection assembly 17 of defective products and the first transfer device used to realize the transfer of chips between the feed conveyor belt 13, the test fixture 14, the screening mechanism 15 and the first discharge conveyor belt 16 Agency18.

[0032] The first frame 11 is installed on the...

Embodiment 3

[0042] This embodiment includes all the content of Embodiment 1, the difference is that in this embodiment, please refer to Figure 11 , The electrical testing device 2 includes a second frame 21 , a first feeding component 22 and a first testing component 23 .

[0043] The second frame 21 is installed on the working platform; the bottom of the second frame 21 is provided with universal wheels to facilitate the transfer of the device, and at the same time in order to ensure the stability of the device in use, the bottom of the second frame 21 is provided with a jacking mechanism , after the working position when moving, the jacking mechanism jacks up the second frame 21, so that the universal wheels are not stressed, and the second frame 21 is not easy to move at this time.

[0044] Such as Figure 16 , Figure 17 As shown, the first feeding assembly 22 includes a feeding mechanism 221 and a first retrieving platform 222. The feeding mechanism 221 is arranged on the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com