Electric industrial brush with cleaning function

An industrial and electric technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of poor cleaning effect, high labor intensity, large space occupation, etc., and achieve better cleaning effect Good, improve quality and effect, good effect of handheld use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

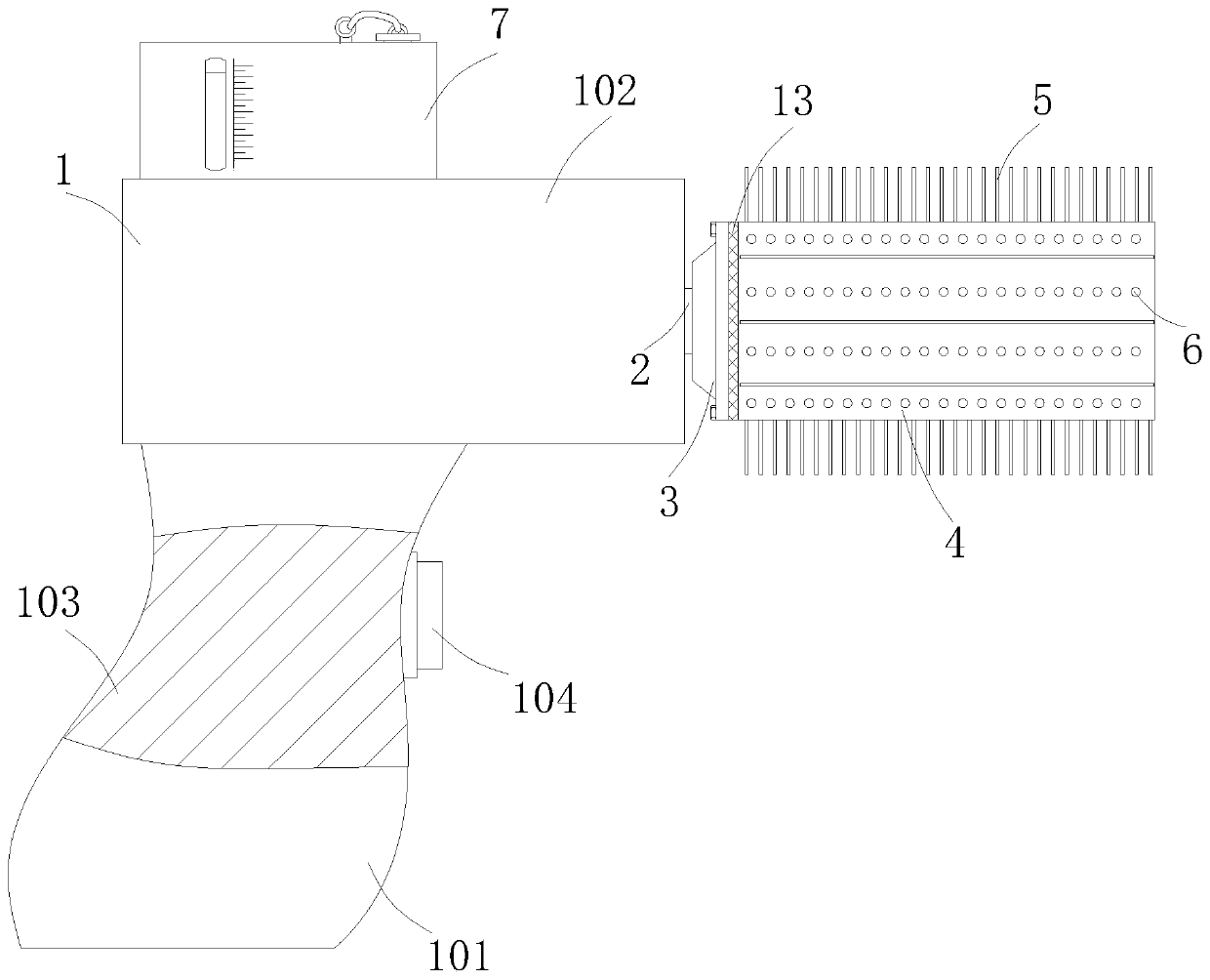

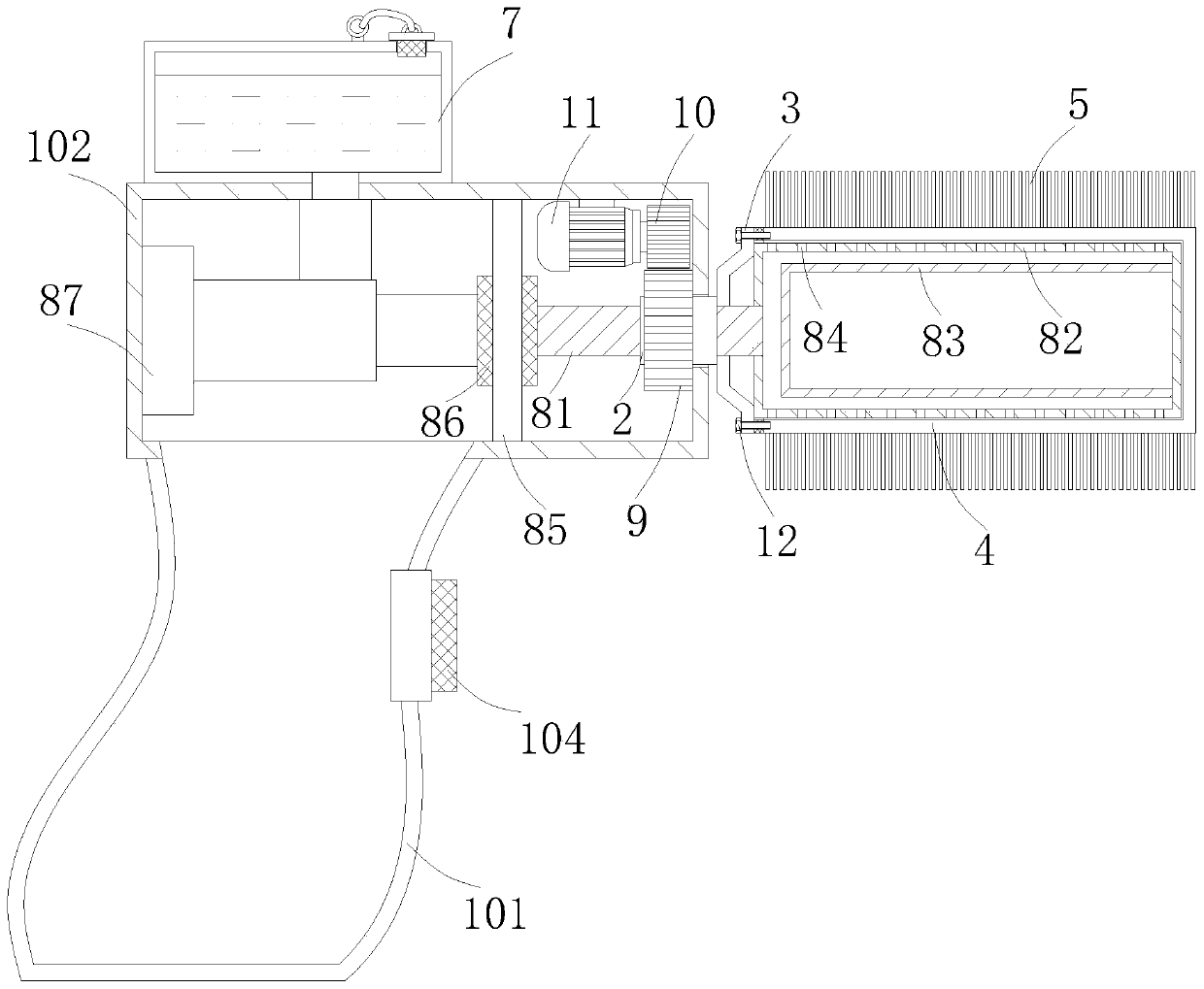

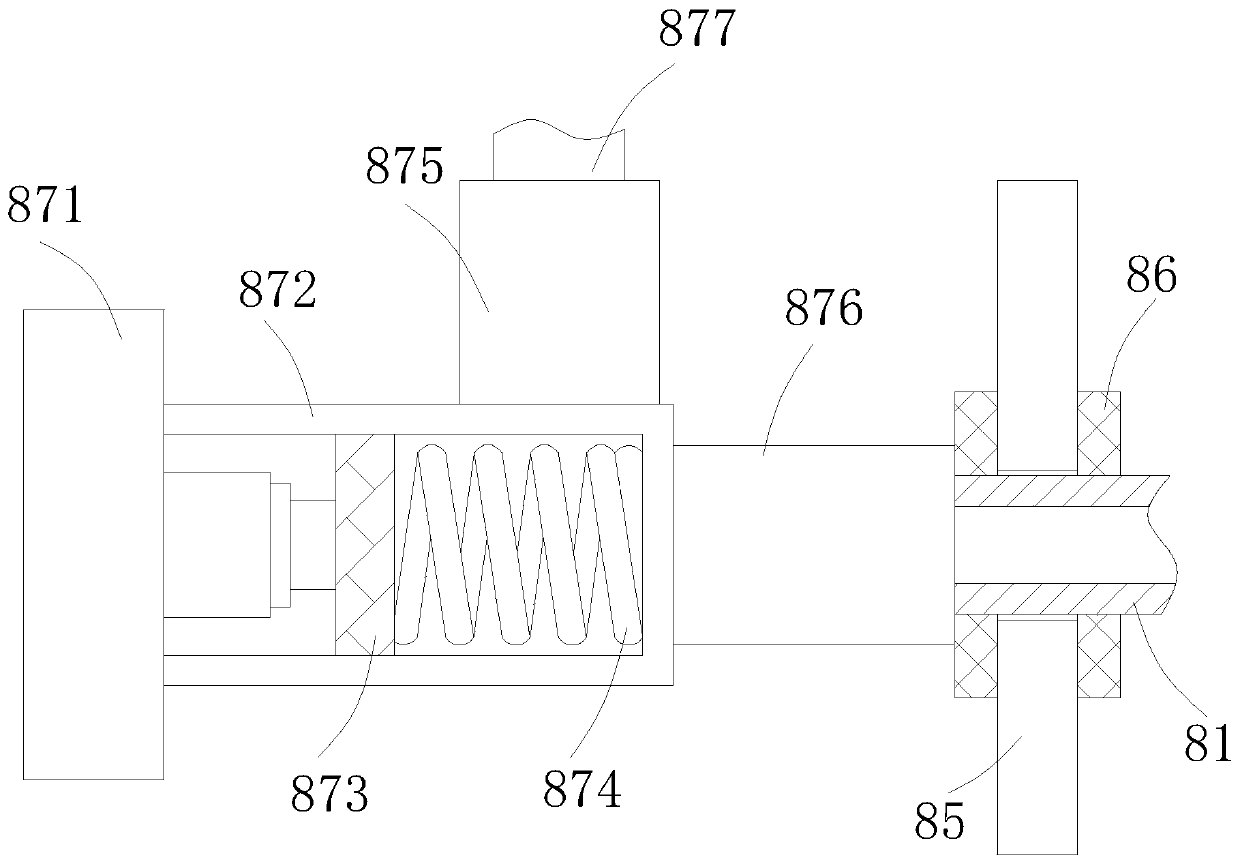

[0031] Attached below Figure 1-4 The present invention is further described with embodiment:

[0032] An electric industrial brush with a cleaning function, comprising a device housing 1, the device housing 1 includes an integrally formed handle part 101 and a core part 102, the handle part 101 is provided with a push switch 104, the core One end of the part 102 is rotated and inserted with a rotating sleeve 2, and one end of the rotating sleeve 2 located at the outer cavity of the core part 102 is equipped with a fixed cover 3, and the other end of the fixed cover 3 is detachably installed with a brush tube 4, which is convenient Replace the excessively worn brush tube 4, the annular outer wall of the brush tube 4 is provided with multiple rows of bristles 5, the inner cavity of the brush tube 4 is provided with a spray cleaning mechanism 8, and the upper end of the core part 102 is equipped with The cleaning liquid tank 7 is used to replenish the cleaning liquid to the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com