Production equipment and production process for edge-turned flange of large pipe

A production process and pipe technology, which is applied in the field of large-scale pipe flanging flange production equipment and its production process, can solve the problems of desoldering, fluid leakage in the pipe, inconvenient transportation, etc., and achieve long service life, firm connection and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

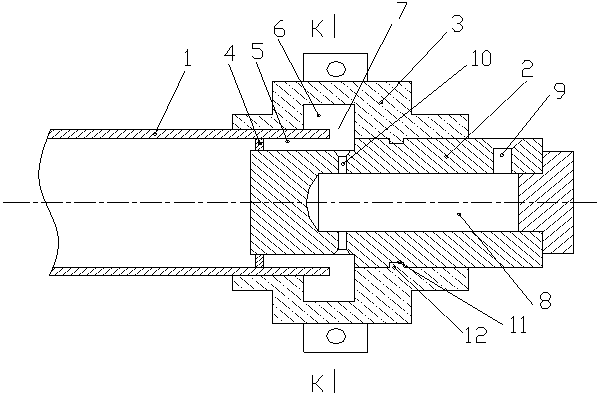

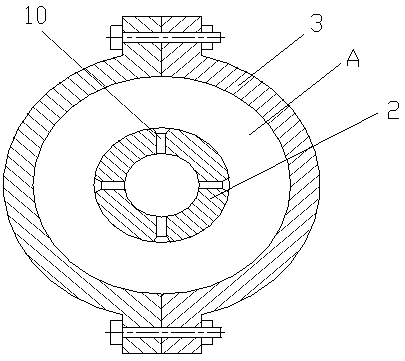

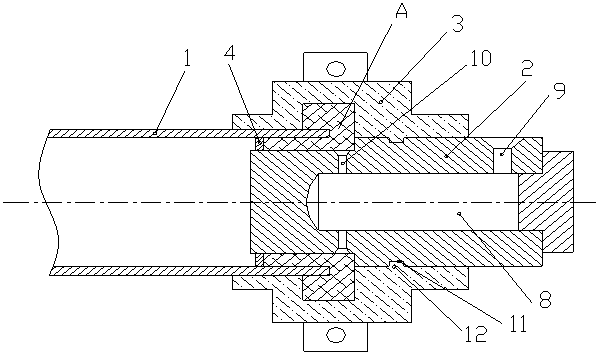

[0023] The large pipe flanging flange manufacturing equipment of the present invention comprises a large pipe 1, the large pipe 1 is a fiber pipe with a large diameter, and a stepped inner shaft 2 extending into the end body of the large pipe, and the stepped inner shaft 2 is divided into small pipe diameter sections and the large pipe diameter section, the outer mold sleeve 3 is clamped between the end of the large pipe material (the end is the position where the flanging flange is to be made) and the outer periphery of the inner shaft (located on the outer periphery of the large pipe diameter section). The die set 3 is composed of two halves, which are fixed by bolts. The first end of the inner shaft of the step (referring to the end facing the large pipe 1) is set with a limit ring for fixing in the end body of the large pipe. Ring 4, the limit ring 4 can be a metal ring, which needs to be fixed on the inner peripheral wall of the end of the large pipe 1 in the process of ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com