Self-heating food split packaging heating structure

A heating structure and separate technology, applied in the direction of food heating container, packaging, packaged food, etc., can solve the trouble, directly pick up the heating box to eat, you need to wait for the heating box to cool down, the use process is cumbersome and other problems, to increase the experience, The effect of easy access and increased heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

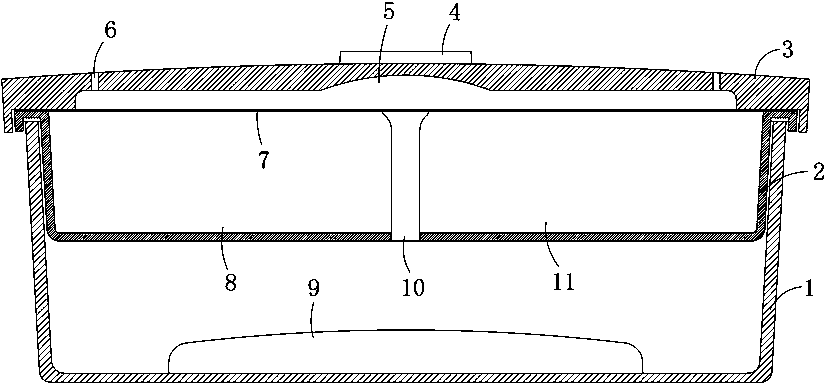

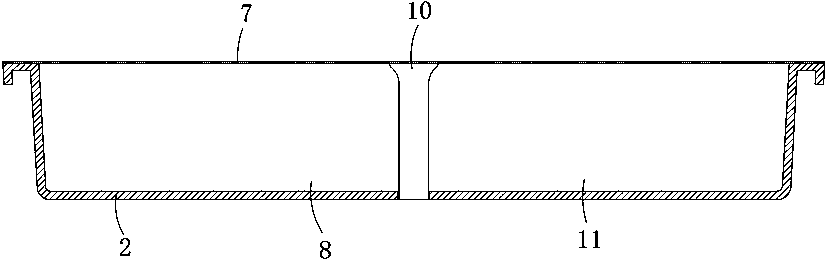

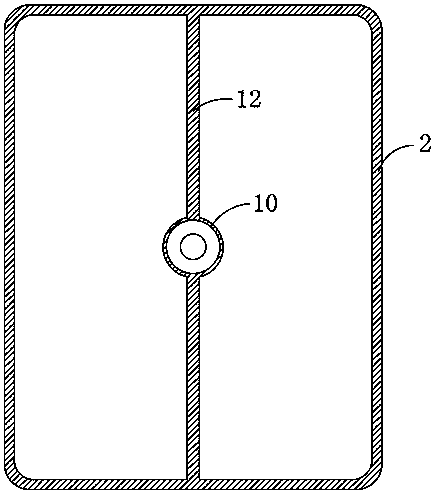

[0019] refer to Figure 1-3 , a self-heating food split packaging heating structure, including a heating vessel 1, the upper port of the heating vessel 1 is provided with a food box 2, and the lower end of the food box 2 is inserted in the heating vessel 1, and the upper end cover of the food box 2 A thermal insulation cover 3 is provided, a steam pipe 10 is inserted on the inner bottom wall of the food box 2, and two dividing plates 12 are symmetrically installed on the outer wall of the steam pipe 10 . Food box 2 is separated into staple food area 8 and dish area 11 by two partitions 12 and steam pipe 10, and the upper port of food box 2 is encapsulated with sealing film 7, and staple food area 8 and dish area 11 heat staple food and dish separately, avoid The soup in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com