Novel hydraulic type grabbing bucket

A hydraulic and new type of technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of material scattering, jaw plate bite is not tight, etc., to achieve the effect of avoiding scattering, ensuring regularity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

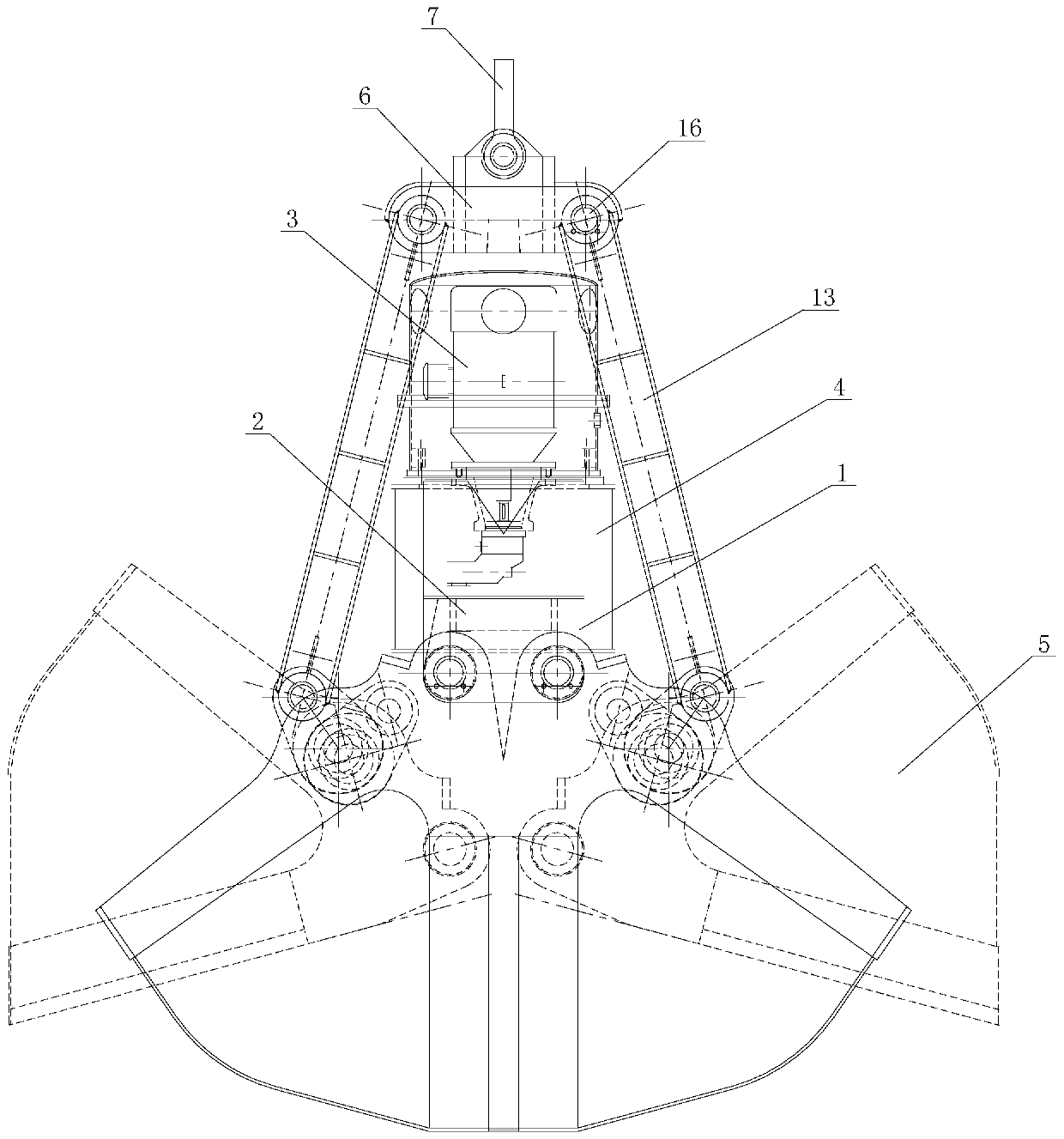

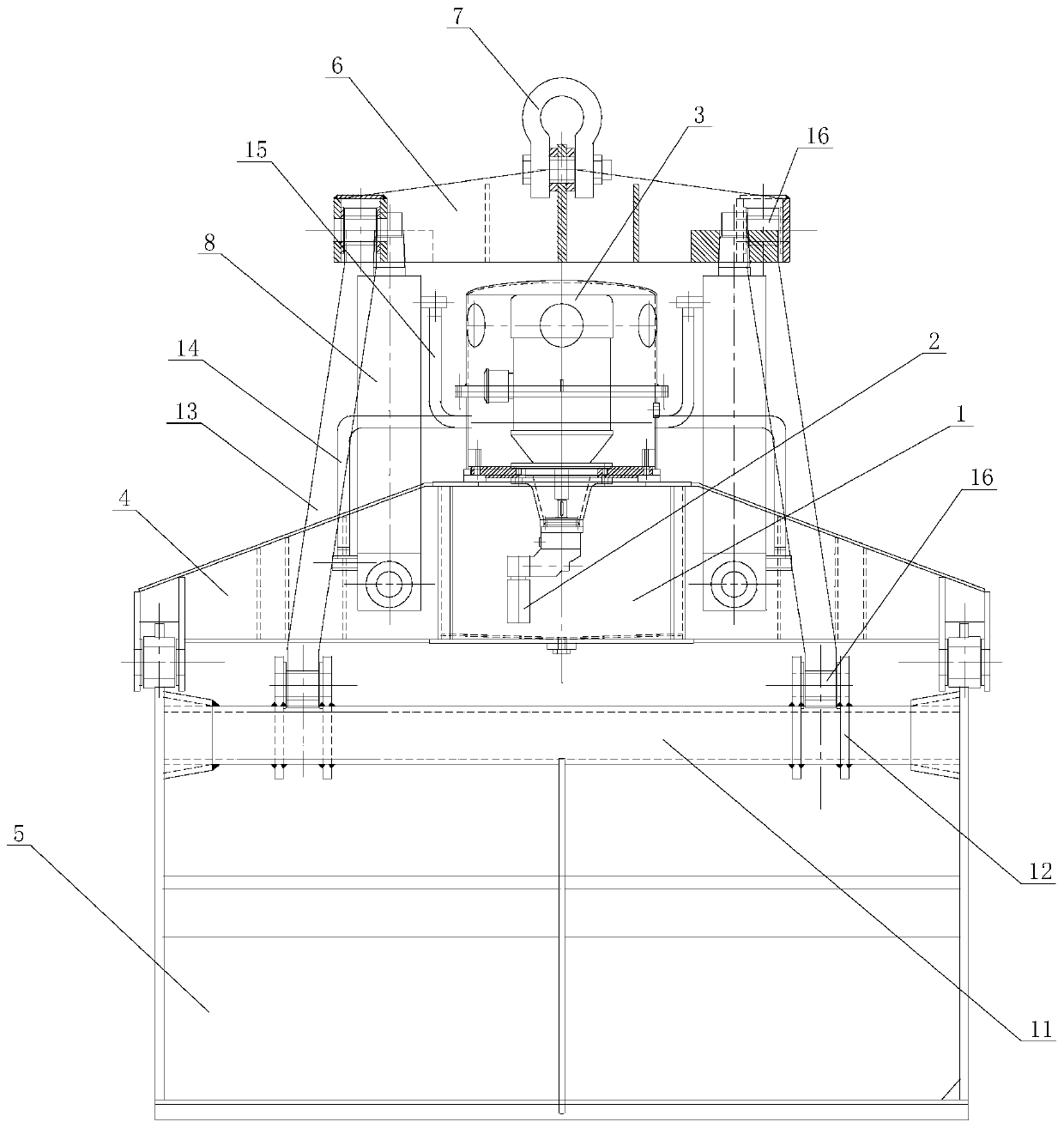

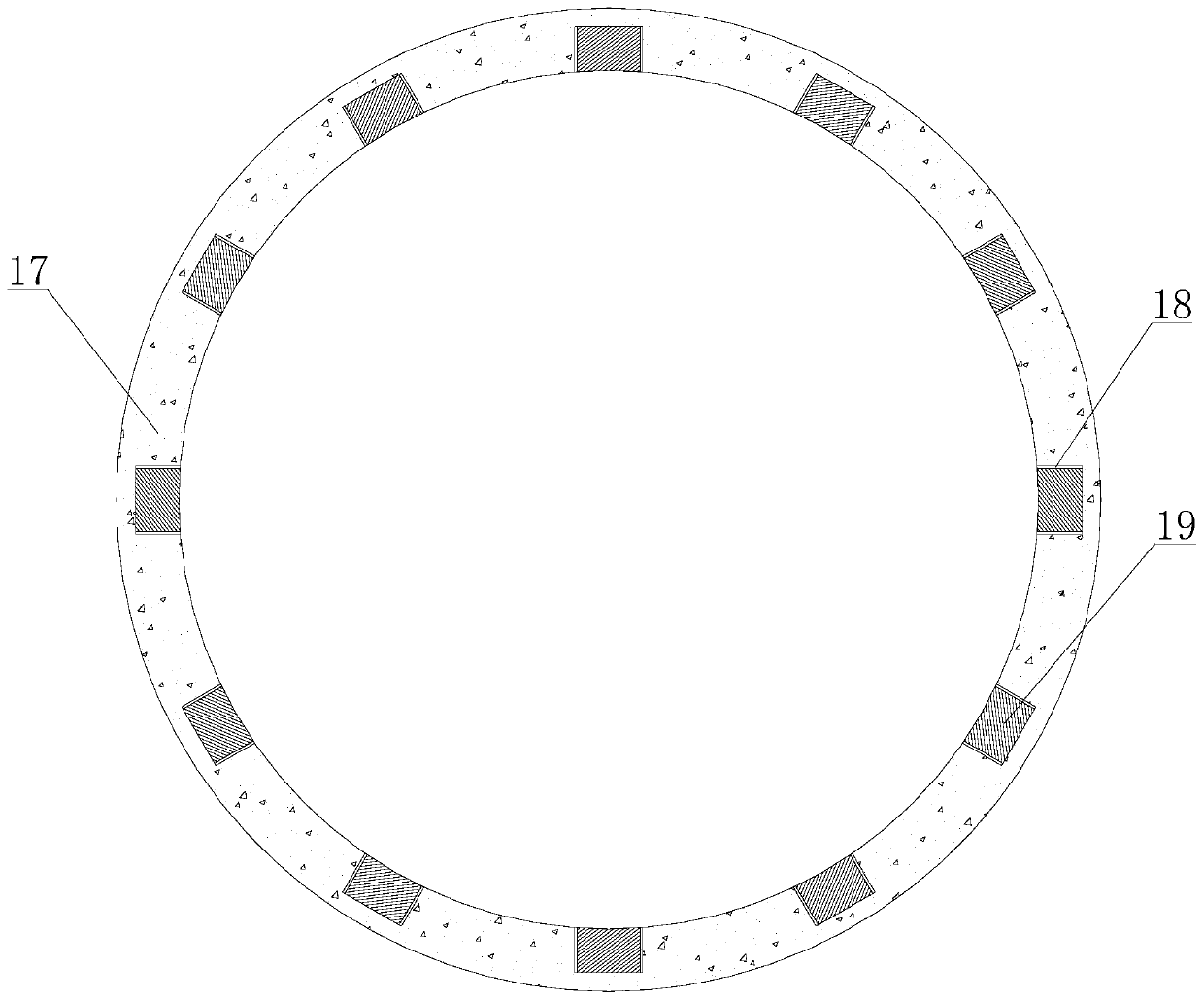

[0017] Such as figure 1 , figure 2 As shown, the present invention provides a novel hydraulic grab bucket, comprising a fuel tank 1, a hydraulic pump 2, a hydraulic pump station 3, a support frame 4, and two mutually engaging jaw plates 5, such as Figure 5 As shown, the plate points of the two jaw plates 5 in this embodiment are respectively an upper plate point 20 and a lower plate point 21. In this embodiment, the upper plate point 20 and the lower plate point 21 are usually integrally cast with the jaw plate 5, The thickness of the upper plate point 20 and the thickness of the lower plate point 21 are half of the thickness of the jaw plate 5, and when the two jaw plates 5 are engaged, the upper plate point 20 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com