Underwater sludge waterproof solidification method and solidification device used by same

A solidification device and silt technology, applied in the field of solidification device and underwater silt water-proof solidification, to improve water quality, solve the problem of land occupation by silt, and ensure the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0033] The invention relates to a water-proof and solidifying method for underwater silt, in which the silt is isolated from the upper water body and then solidified.

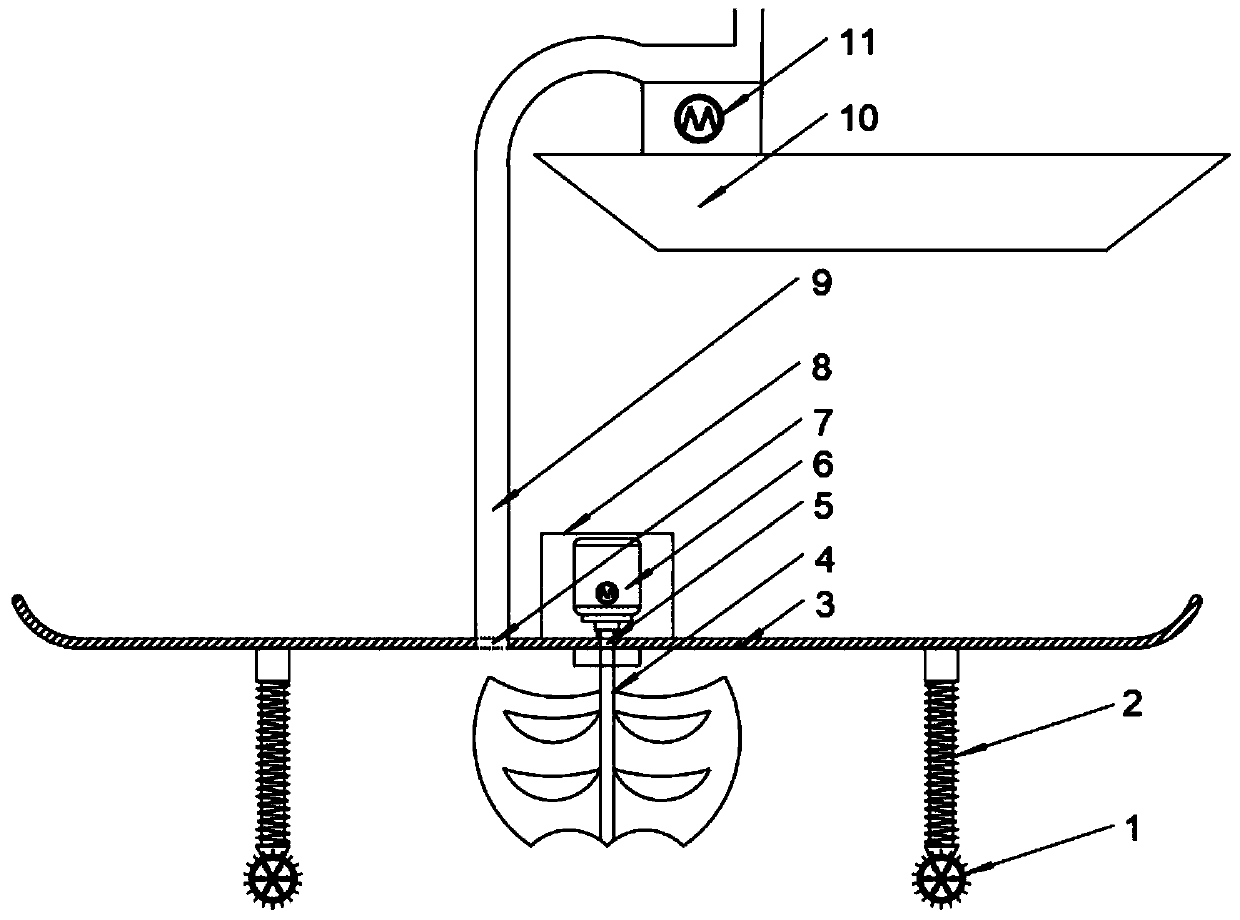

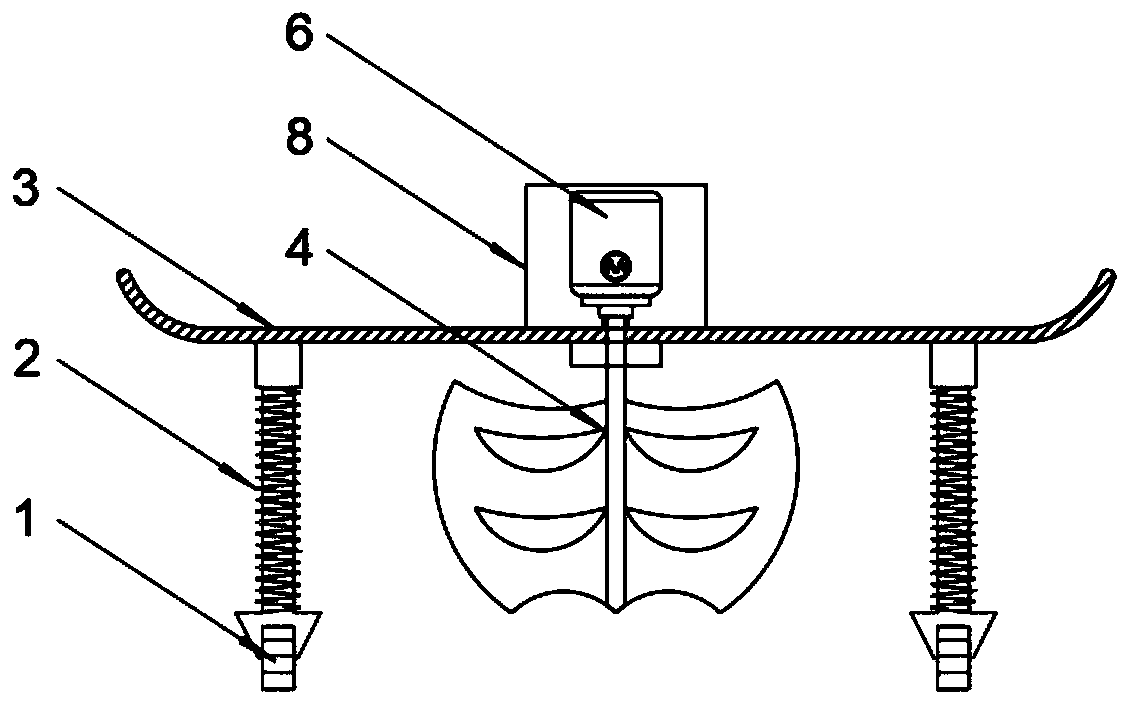

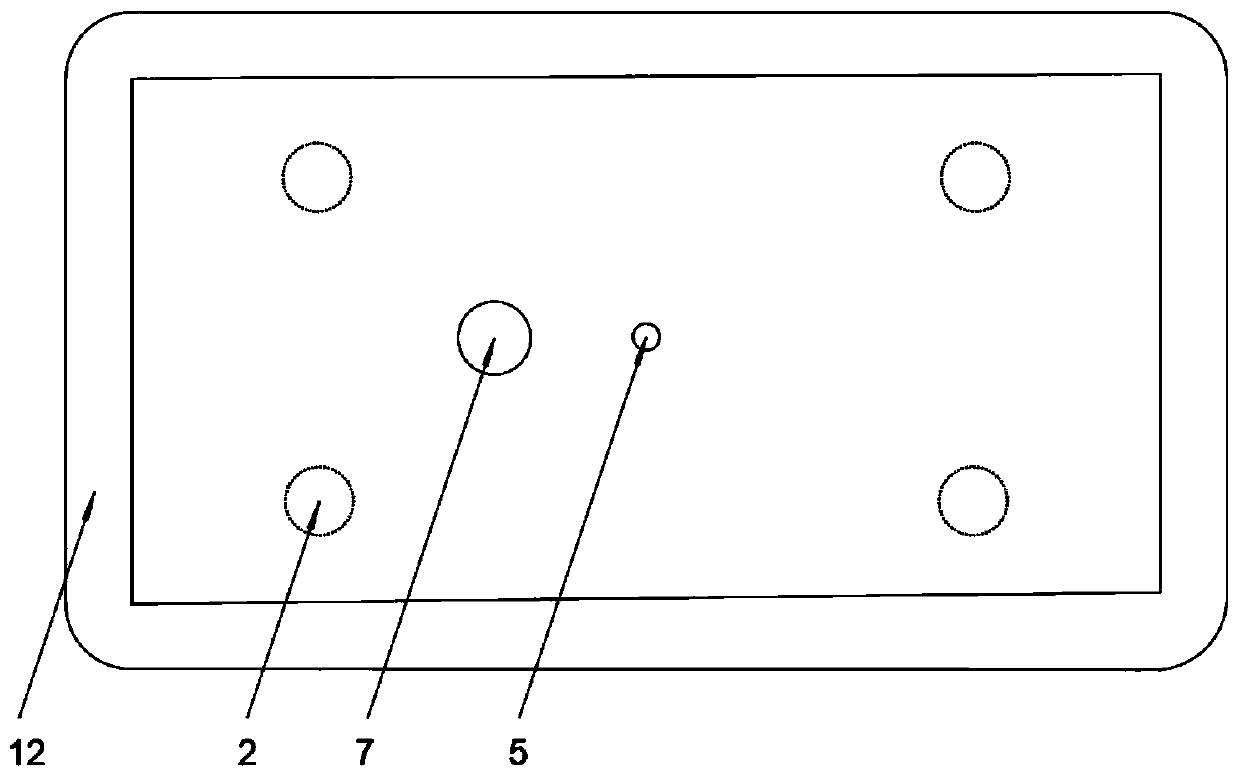

[0034] Such as figure 1 , figure 2 with image 3 Shown, a kind of curing device for water-proof solidification of underwater silt, including stirring system, water-proof system, curing agent delivery system and walking system; The water-proof system is used to isolate the mud from the upper water body, and the stirring The system is used to mix the isolated sludge with the curing agent, the curing agent delivery system is used to transport the curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com