Bottle bottom separating device of vertical tube type bottle making machine

A technology for separating devices and controlling bottles, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass reshaping, etc. It can solve problems such as reducing product qualification rate and yield, increasing production and maintenance costs of enterprises, and damage to the surface of processed bottles. , to achieve the effect of improving the work efficiency of the enterprise, reducing the labor force and labor intensity, and reducing the daily maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

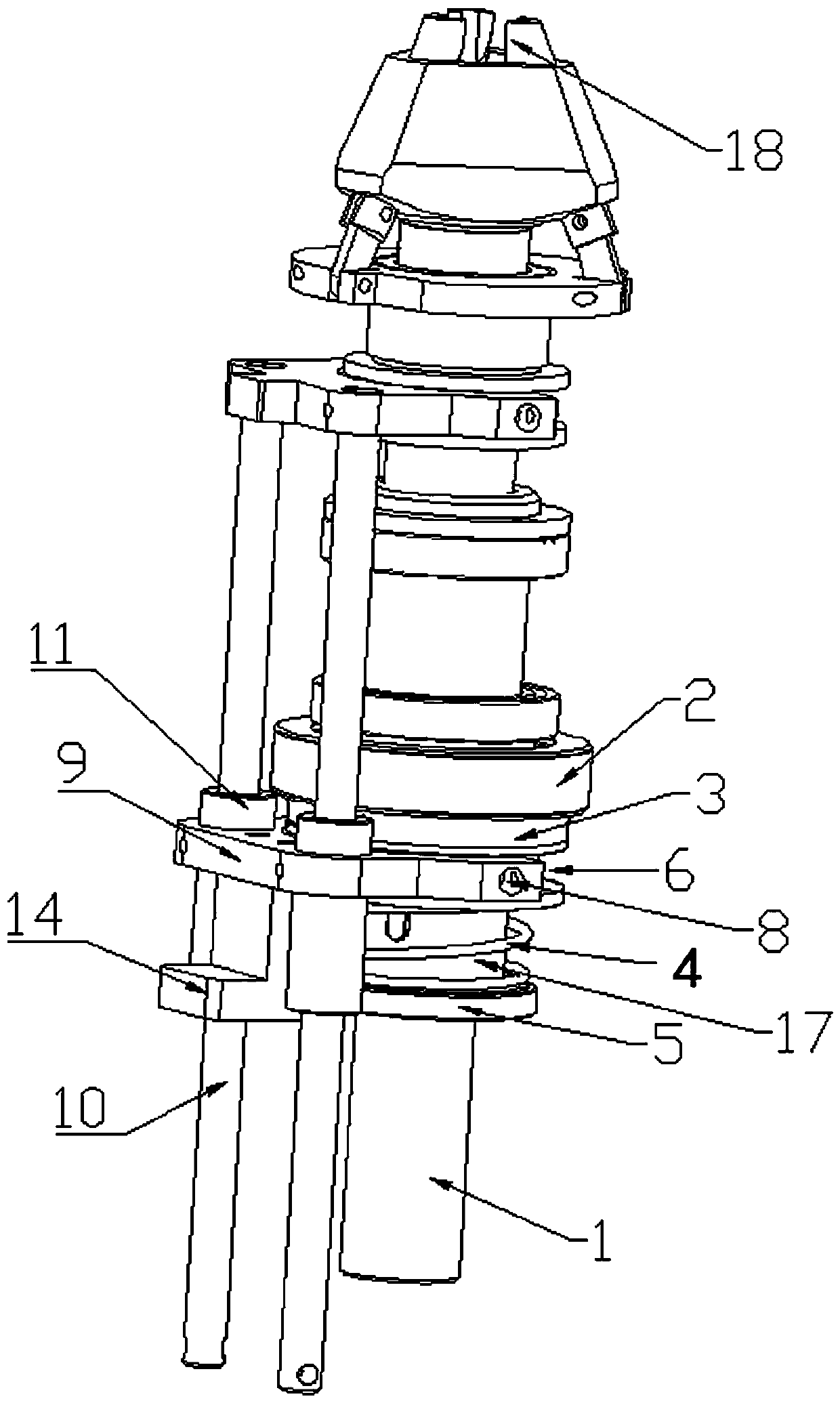

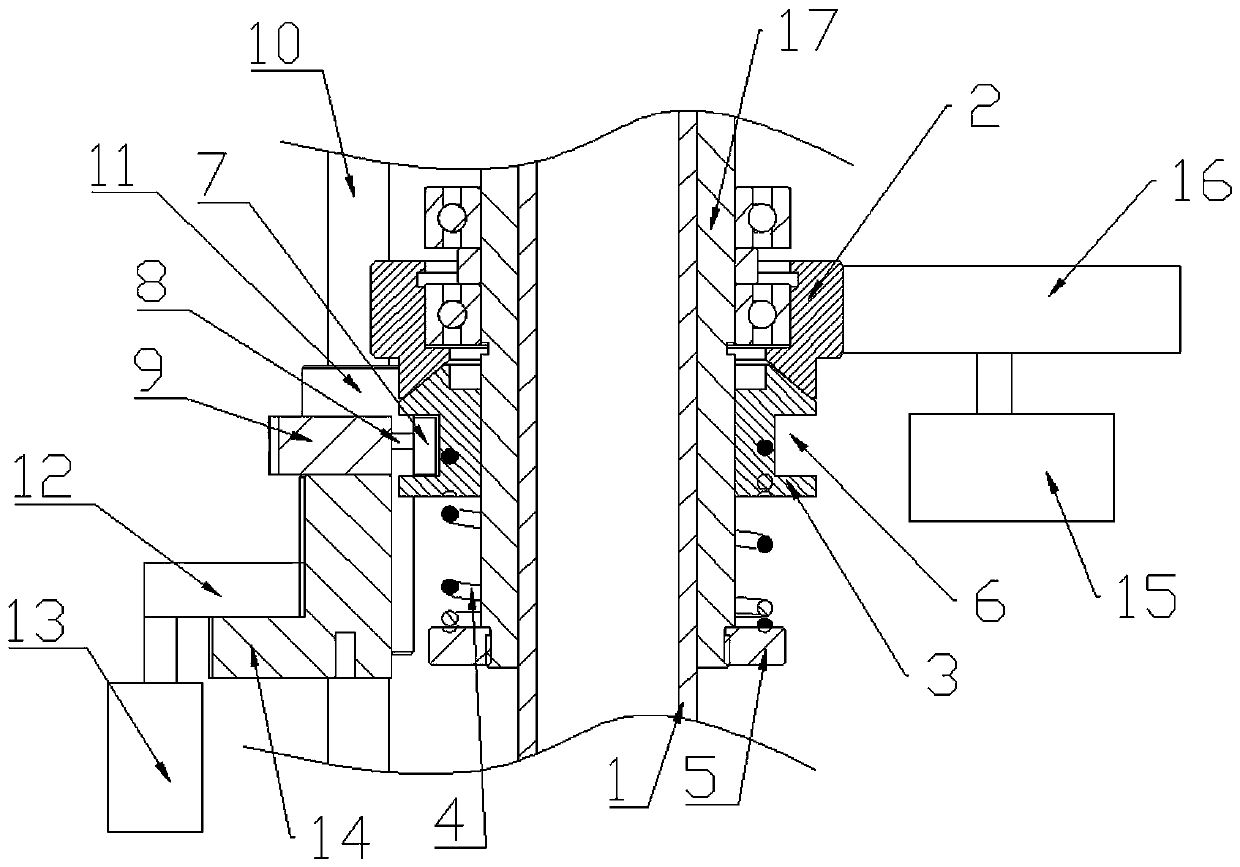

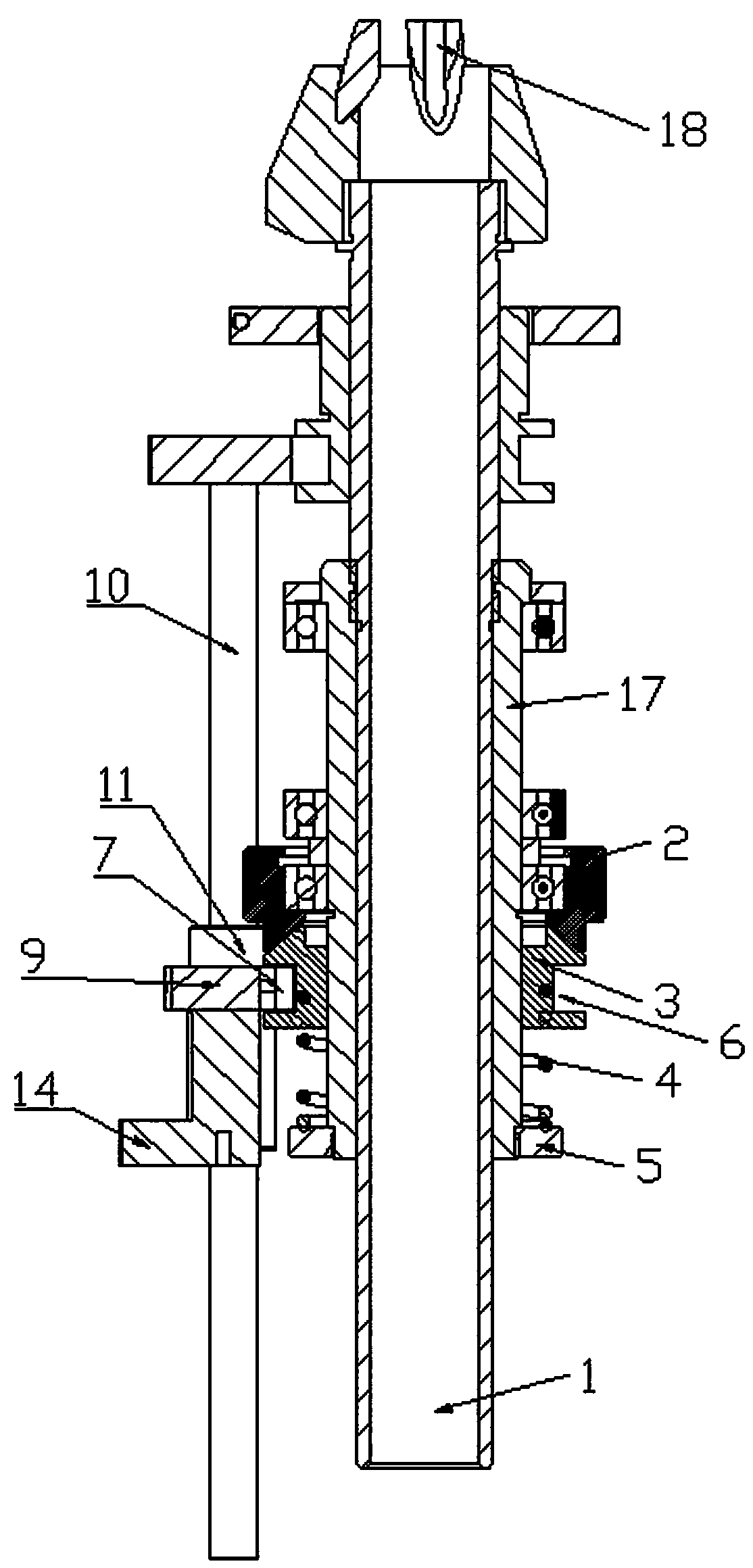

[0032] Example A bottle bottom separation device for vertical control bottle mechanism

[0033] In this embodiment, during normal bottle production, the reset mechanism drives the upper clutch 2 to contact the lower clutch 3, so that the chuck jaw 18 is driven by power to rotate; when the robot picks up the bottle, the upper clutch 2 and the lower clutch 3 are driven by the driving mechanism Phase separation makes chuck jaw 18 stop rotating.

[0034] Such as Figure 1 to Figure 3 As shown, this embodiment includes a bottle drop tube 1 with a bottle tube inside. The bottle drop tube 1 is in the shape of a round tube. The upper part of the bottle drop tube 1 is fixed with a chuck assembly, and the lower part of the bottle drop tube 1 is connected with an outer sliding sleeve through a sliding key. 17.

[0035] 1. Chuck components

[0036] The collet assembly is fixed on the collet assembly on the bottle drop tube 1 top. The collet assembly adopts the collet assembly on the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com