Aluminosilicate glass and preparation method

A kind of aluminosilicate glass and glass technology, which is applied in branch office equipment, telephone communication, electrical components, etc., can solve the problems of high equipment investment and production cost, poor process stability, low yield rate, etc., and achieve improved drop resistance stability , Improve the effect of falling and crushing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

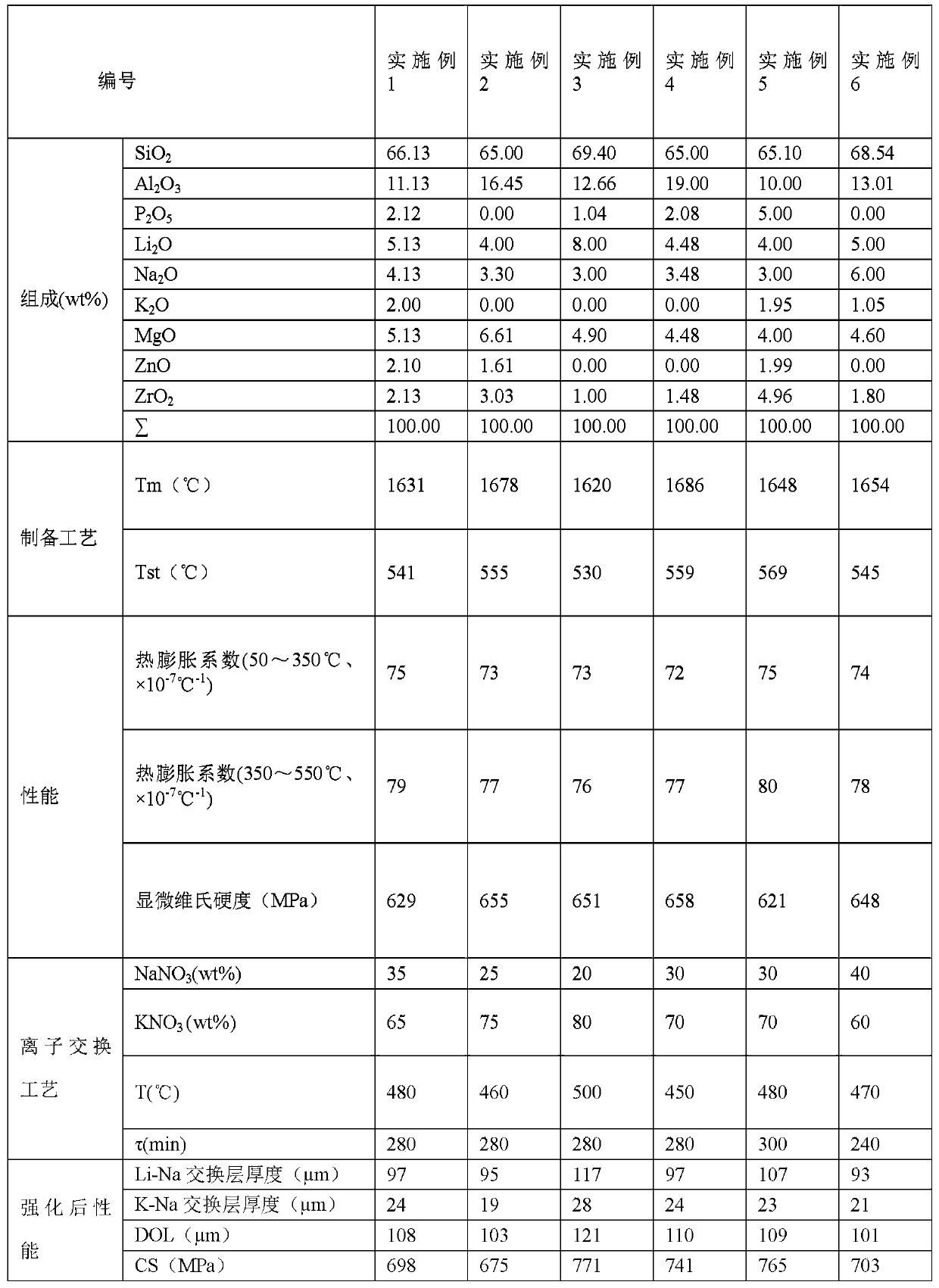

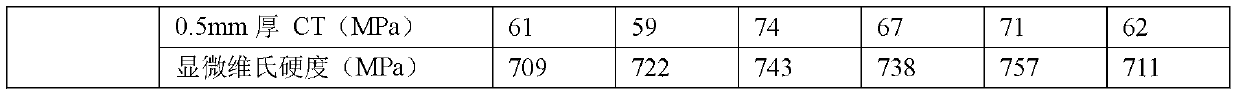

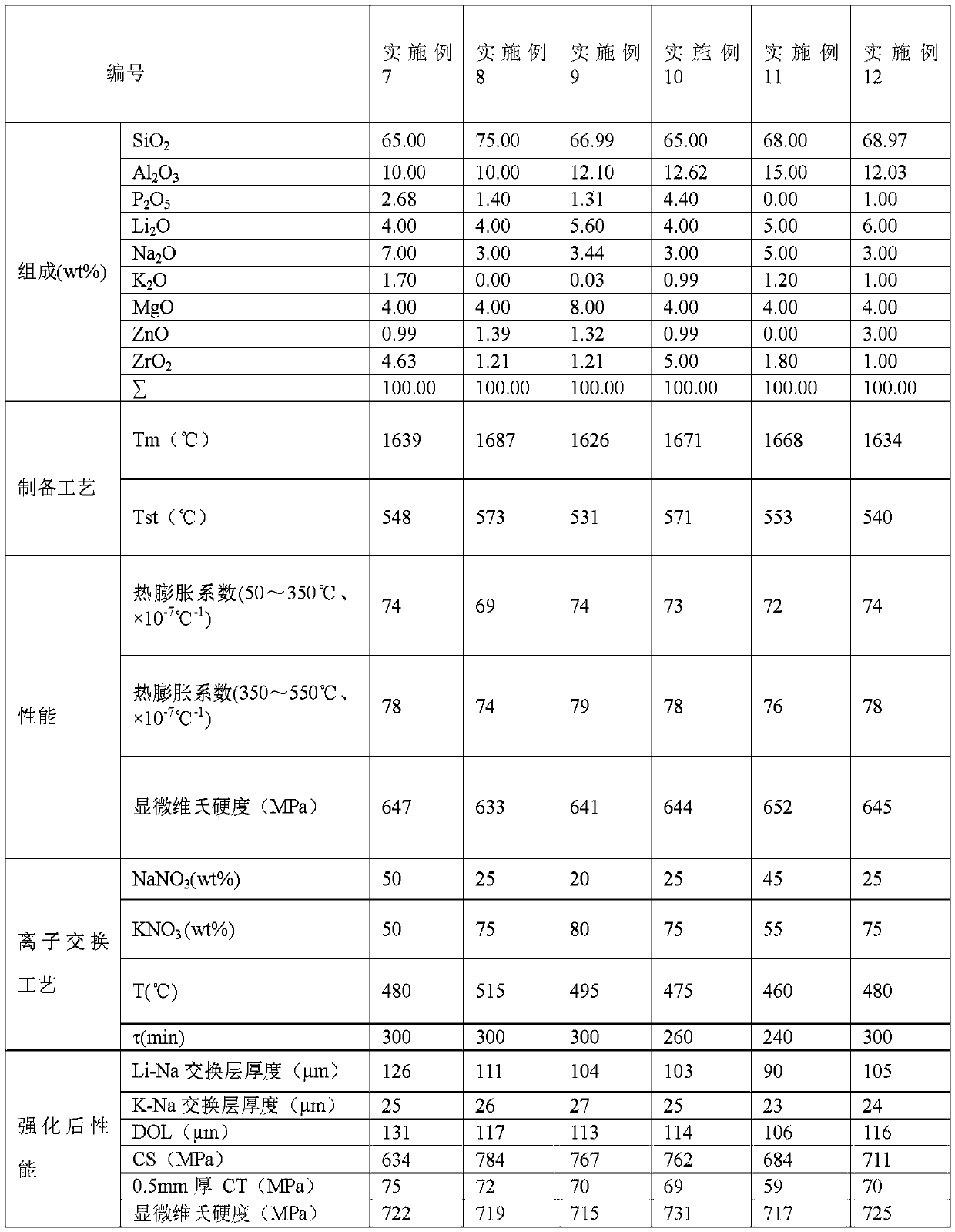

[0052] In Tables 1-4, commonly-used glass raw materials such as oxides and carbonates, etc. were appropriately selected to have the compositions shown in the tables, weighed to make batches greater than 500 g, and thoroughly stirred and mixed. Put the batch mixture into a platinum crucible larger than 400ml, put the platinum crucible into a silicon-molybdenum furnace, heat up to 1670°C, melt and clarify for more than 8 hours, homogenize it and cast it into a mold, and anneal at a temperature below 750°C Precision annealing is carried out at high temperature, and subsequently bulk glass is obtained. Carry out precision wire cutting to this bulk glass, and all carry out grinding and polishing to two surfaces, obtain the ultra-thin glass of two kinds of different thicknesses that diagonal length dimension is 6 inches, thickness is 1.1mm and 0.5mm.

[0053] The size and thickness of the above ultra-thin glass can be adjusted arbitrarily according to the needs of end customers of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com