Mineral soil conditioner produced by utilizing fly ash and preparation method thereof

A technology of soil conditioner and fly ash, which is applied in the field of agricultural resource utilization of fly ash, can solve the problems of insufficiently advanced technology and low efficiency of resource utilization, so as to improve the quality of soil environment and improve the level of high-efficiency comprehensive utilization , The effect of reducing the amount of farmland

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

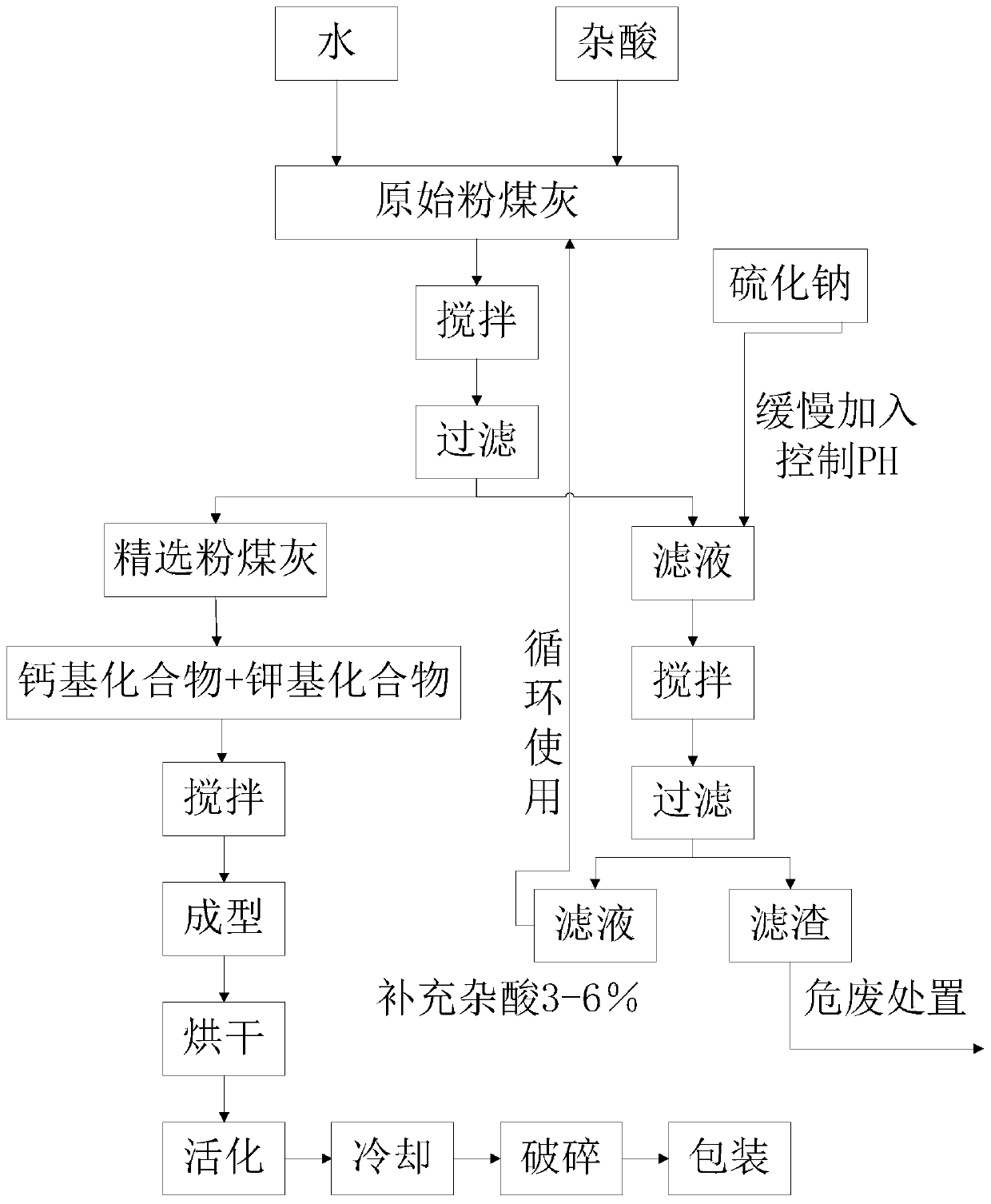

Method used

Image

Examples

Embodiment 1

[0034] A thermal power plant in Inner Mongolia has an annual output of 1 million tons of fly ash, of which the silica content is 57.67wt%, potassium oxide content is 0.42wt%, alumina content is as high as 17.32wt%, calcium oxide content is 2.15wt%, iron oxide content 1.35wt%, of which the heavy metal content is: lead content 121.73mg / kg, cadmium content 2.15mg / kg, mercury content 0.74mg / kg, copper content 7.97 mg / kg.

[0035] Its operation process is:

[0036] (1) After mixing fly ash with humic acid, hydrochloric acid, sulfuric acid, nitric acid, and perchloric acid at a solid / liquid ratio of 1:1 g / mL, ultrasonically for 20 minutes , stirred at 85r / min stirrer speed for 55 minutes to make it fully mixed, and then filtered to obtain the removal rates of heavy metals in fly ash as follows: lead 67%, cadmium 86%, mercury 66%, copper 87% ;

[0037] (2) Add sodium sulfide solution with a concentration of 0.15 mol / L to the filtrate obtained after filtering in step (1), and the pH...

Embodiment 2

[0041] A thermal power plant in Liaoning has an annual output of 1.6 million tons of fly ash, of which the silica content is 52.67wt%, the alumina content is 21.76wt%, the potassium oxide content is 0.72wt%, the calcium oxide content is 3.15wt%, and the iron oxide content is 3.57wt%, of which the heavy metal content is: lead content 101.30mg / kg, cadmium content 1.71mg / kg, mercury content 0.78 mg / kg, copper content 19.48 mg / kg.

[0042] Its operation process is:

[0043] (1) Mix the fly ash with the mixed acid solution of humic acid, hydrochloric acid, sulfuric acid, hydrofluoric acid, nitric acid and perchloric acid with a concentration of 0.57mol / L at a solid / liquid ratio of 1:2.5g / mL Finally, after 15 minutes under the action of ultrasonic waves, stir for 60 minutes under the stirring speed of 150r / min to make it fully mixed, and then filter to obtain the removal rates of heavy metals in fly ash as follows: lead 78%, cadmium 82 %, Mercury 49%, Copper 70%;

[0044] (2) Add ...

Embodiment 3

[0048] A thermal power plant in Hebei Province has an annual output of 3 million tons of fly ash, of which the silica content is 46.67wt%, the alumina content is 15 wt%, the potassium oxide content is 0.92wt%, the calcium oxide content is 6.15wt%, and the iron oxide content The content of heavy metals is 2.71wt%, of which the content of heavy metals is: lead content 71.73mg / kg, cadmium content 1.13mg / kg, mercury content 1.07 mg / kg, copper content 38.02 mg / kg.

[0049] Its operation process is:

[0050] (1) After mixing the fly ash with the mixed acid solution of humic acid, hydrochloric acid, sulfuric acid, hydrofluoric acid, acid and perchloric acid with a concentration of 0.9mol / L at a solid / liquid ratio of 1:5 g / mL , after ultrasonication for 27 minutes, stirred at 195r / min stirrer speed for 115 minutes to make it fully mixed, and then filtered to obtain the removal rates of heavy metals in fly ash as follows: lead 72%, cadmium 73%, mercury 73% %, copper 79%;

[0051] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com