Microorganism sample processing inspection bench

A technology for testing benches and microbes, which is applied in the field of testing benches, can solve the problems of inconvenient testing process, unfavorable environmental protection, time-consuming and labor-intensive problems, and achieve the effect of simple and convenient moving process and good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

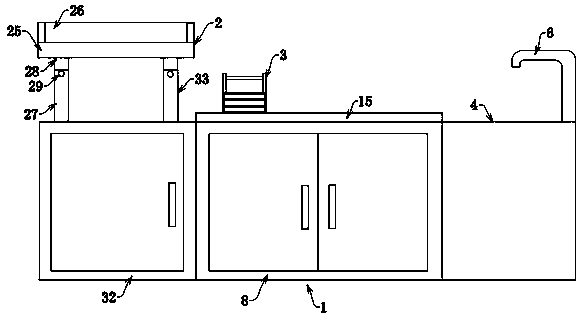

[0029] Embodiment one, as figure 1 As shown, the microbial sample processing inspection platform includes an inspection platform 1, and the upper end surface of the inspection platform 1 is provided with a sample detection platform 2, a sample placement platform 3 and a cleaning platform 4 in sequence from left to right. The inspection platform 1 is in the shape of a cuboid.

[0030] The sample testing platform 2 is connected to the testing platform 1 through the lifting column 33 to form a structure in which the sample testing platform 2 can be raised or lowered relative to the testing platform 1 . Among them, the lifting column 33 can be made of stainless steel metal material, and the two ends of the lifting column 33 can be respectively connected with the sample detection table 2 and the inspection table 1 by screws. There are four lifting columns 33 and they are evenly distributed between the sample detection table 2 and the inspection table between station 1. Such settin...

Embodiment 2

[0034] Embodiment 2, on the basis of the foregoing embodiments, further, as Figure 5 As shown, the inside of the water storage tank 5 is overlapped with a hollow filter tank 10, that is, the filter tank 10 is made of metal wire, and the edge of the filter tank 10 is provided with a snap-in strip, and the water storage tank 5 is provided with a snap-in slot. It is overlapped inside the water storage tank 5 through the cooperation of the snap-in strips and the snap-in slots. There is a gap between the bottom of the filter tank 10 and the bottom of the water storage tank 5 .

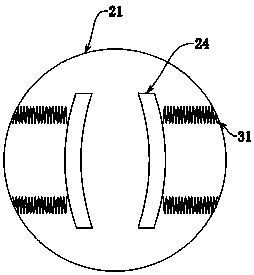

[0035] The bottom end of the filter tank 10 is clamped with a water purification layer 11, the water purification layer 11 is suitable for the size of the filter tank 10, and the water purification layer 11 is directly stuck in the filter tank 10, such as Figure 6 As shown, the water purification layer 11 includes an activated carbon particle layer 12 , PP cotton 13 and RO reverse osmosis membrane 14 seq...

Embodiment 3

[0036] Embodiment 3. On the basis of the above-mentioned embodiments, further, the upper end surface of the inspection table 1 is provided with a slide rail 15, and the slide rail 15 is fixedly connected to the upper end surface of the inspection table 1 by screws, such as Figure 7 and 8 As shown, the section of the inner chamber of the slide rail 15 is convex, and the length of the slide rail 15 is equal to the distance between the sample detection platform 2 and the cleaning platform 4 .

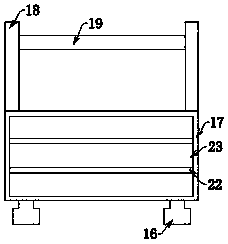

[0037] Such as figure 2 As shown, the bottom end of the sample placement platform 3 is provided with a slider 16 that is compatible with the slide rail 15. The slider 16 can be integrally formed with the sample placement platform 3. There are at least two sliders 16, which are distributed at the bottom of the sample placement platform 3. On the left and right sides of the end face, the size of the inner cavity of the slide block 16 is adapted to that of the slide rail 15 . The sample p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com