A heat self-balancing system and construction method for preventing and controlling freezing damage in tunnels in cold regions

A technology for tunnels and construction methods in cold regions, applied in the field of tunnels, can solve problems such as high cost, fire safety, and large labor costs, and achieve the effects of easy transportation and installation, reduced specification requirements, and good heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

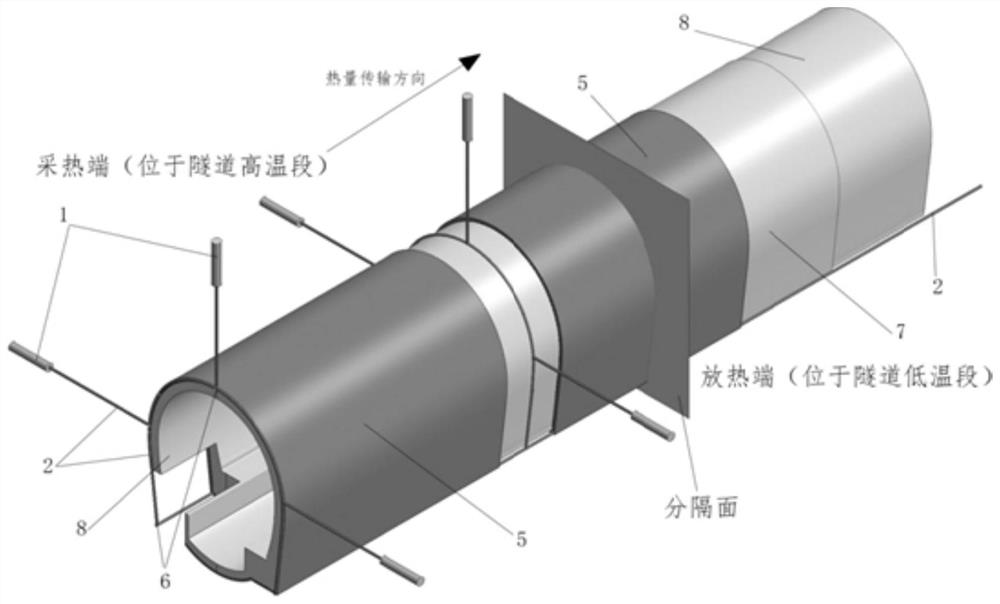

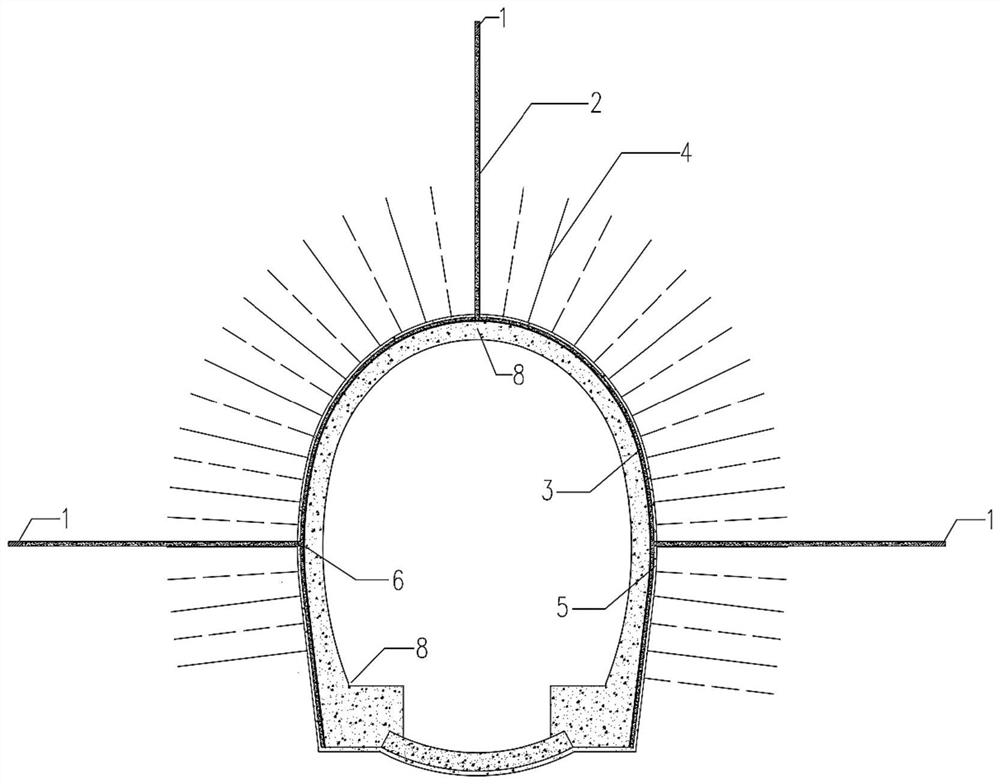

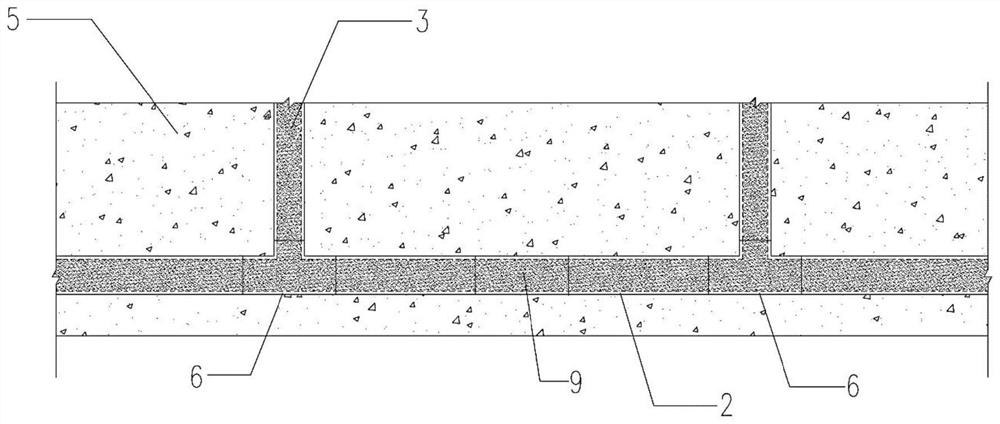

[0037] In one embodiment of the present invention, as Figure 1-4 As shown, a heat self-balancing system for the prevention and control of tunnel frost damage in cold regions is provided, which includes a primary support structure 5, a waterproof board and a secondary lining structure 8 from the outside to the inside. The anchor rod 4, the superconducting heat pipe 2 and the heat collecting device 1, the lower end of the superconducting heat pipe 2 is provided with a three-way joint 6, and the three-way joint 6 is arranged between the primary support structure 5, the waterproof board and the secondary lining structure 8, and the superconducting heat pipe 2 The lower ends of the heat pipes 2 are all provided with a tee joint 6, and the adjacent tee joints 6 are connected by the superconducting heat pipe 2 and the double-way joint 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com