Symmetrical cantilever rod type dynamic vibration absorber

A dynamic vibration absorber and cantilever rod technology, applied in non-rotational vibration suppression, screws, nuts and other directions, can solve the problems of installation point impedance, cumbersome frequency modulation process, reduce frequency modulation work and other problems, achieve stable performance, fast frequency modulation, and reduce frequency modulation work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

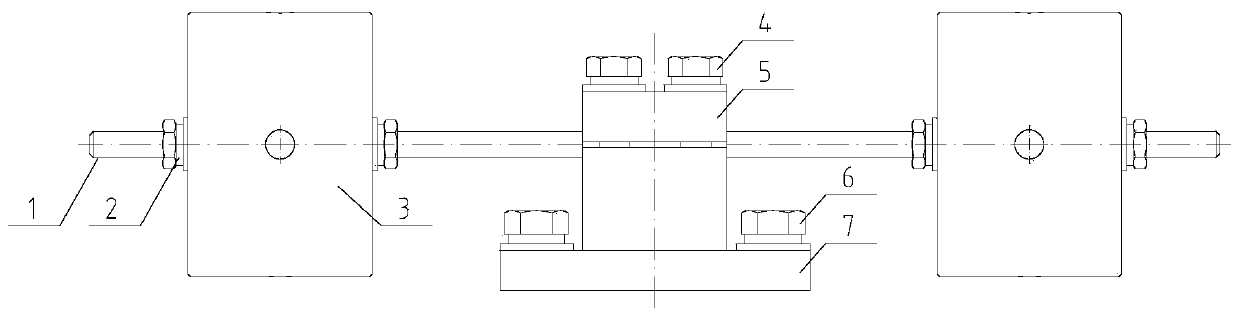

[0019] Embodiment 1, this embodiment is a symmetrical cantilever rod type dynamic vibration absorber, including a cantilever rod 1, a mass block fastener 2, a mass block 3, an upper support fastener 4, an upper support 5, a lower support tight Firmware 6 and lower support 7. Two mass blocks 3 are fixed on the cantilever bar 1 through fasteners 2, and are arranged symmetrically with respect to the upper and lower supports 5 and 7. This structure can make the vibration-absorbing structure symmetrical; the cantilever The rod 1 is clamped between the upper support 5 and the lower support 7; the upper support 5 is connected with the lower support 7 through the fastener 4; the lower support 7 is connected with the equipment through the fastener 6.

[0020] The lower part of the upper support 5 has a rectangular slot, and the top of the lower support 7 has a rectangular slot, and the upper support 5 and the rectangular slot of the lower support 7 cooperate with each other; the middle ...

Embodiment 2

[0032] Embodiment 2, on the basis of Embodiment 1, the material of the mass block 3 can be changed from steel to materials such as copper with higher density. In this way, the size of the mass element can be further reduced, making the shock absorber more compact.

Embodiment 3

[0033] Embodiment 3, on the basis of Embodiment 1 or 2, the mass block 3 can be changed from cylindrical to square or rectangular to meet the requirements of some special frequencies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com