Rotating equipment foundation natural frequency adjusting device and adjusting method thereof

A technology of natural frequency and adjustment device, applied in the direction of mechanical equipment, engine base, supporting machine, etc., can solve the problem of rotating equipment away from the resonance area, etc., and achieve the effect of simple structure and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technology of the present invention is further described below:

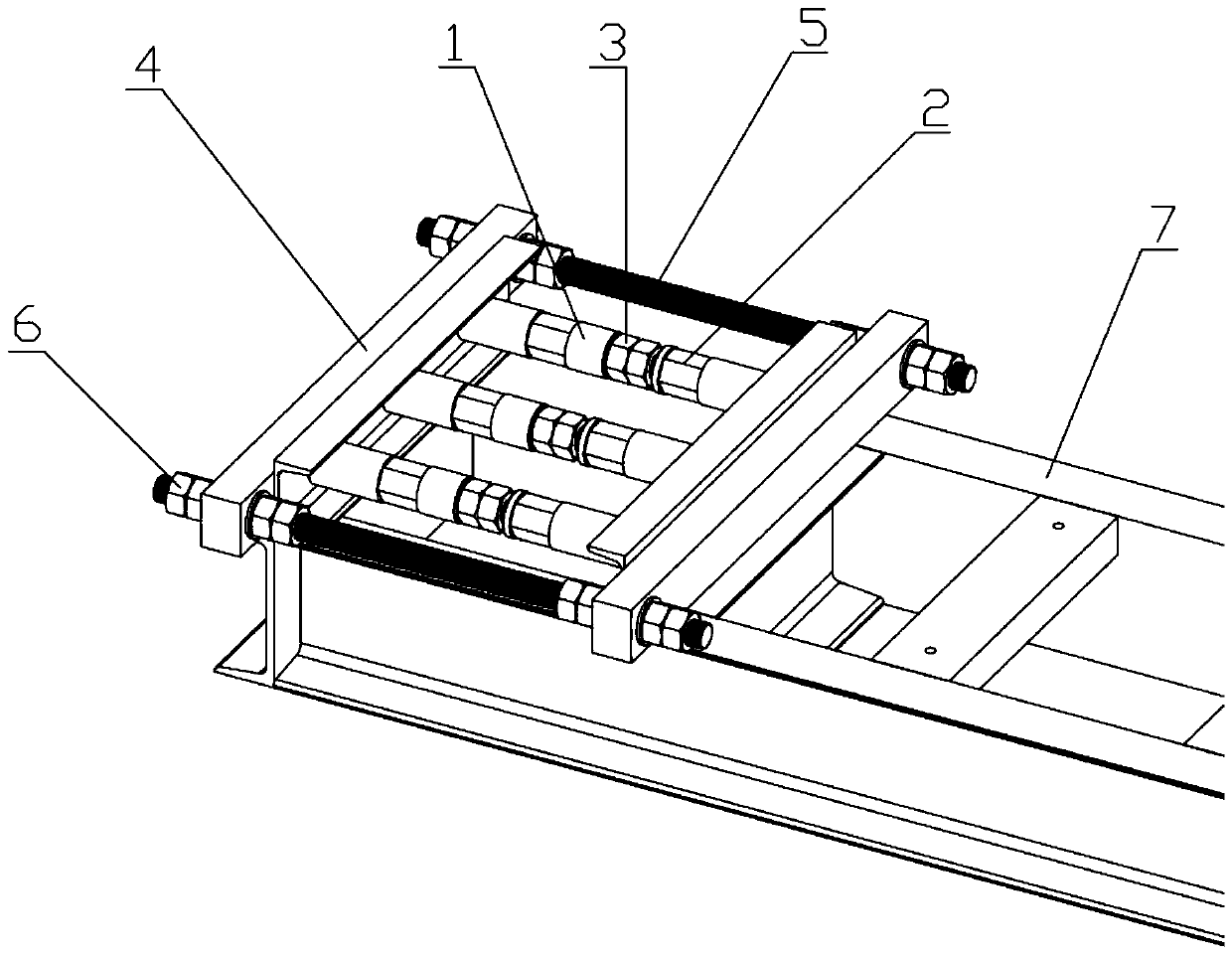

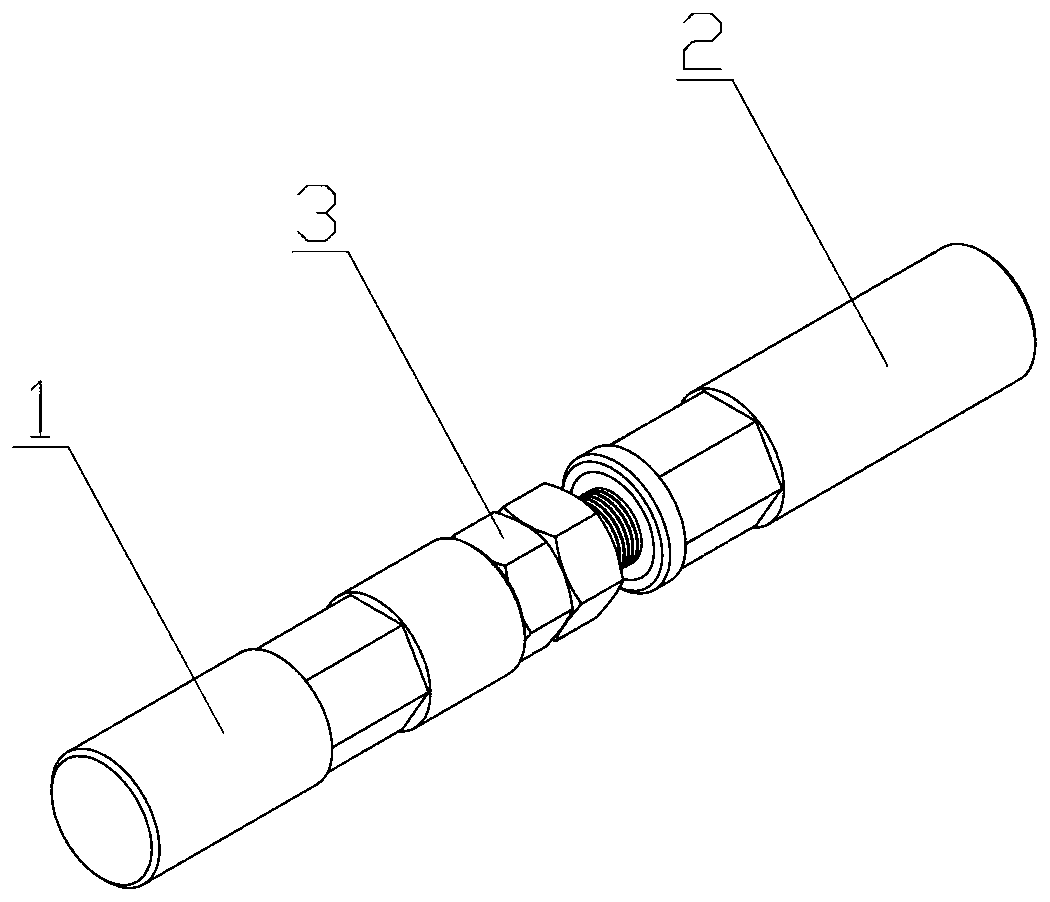

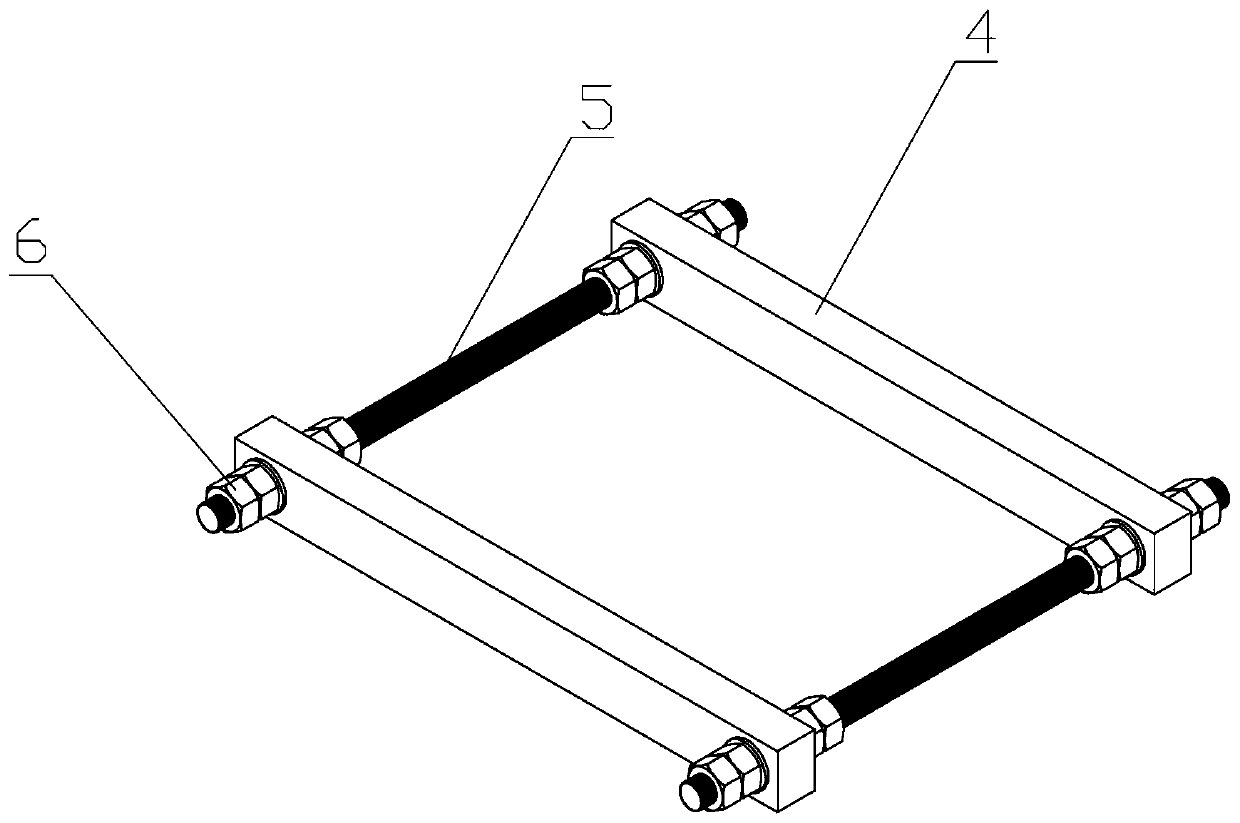

[0023] Such as Figures 1 to 3 As shown, a device for adjusting the natural frequency of the foundation of rotating equipment includes: equipment foundation base 7, several ribs 4, screw jacks, screw rods 5, and nuts B 6; each screw jack includes: a screw jack The female part 1, a screw jack male part 2 and several nuts A3, the screw jack female part 1 and the screw jack male part 2 are threaded through the nut A3; the rib plate 4 and the screw rod 5 are threaded through the nut B6 A frame structure is formed and placed outside the equipment foundation base 7, and the screw jack is axially loaded into the equipment base base 7 interior.

[0024] The screw jack female part 1 is axially provided with threaded holes; the radial outer surface of the screw jack female part 1 is processed with hexagons for wrench fastening; the screw jack male part 2 is axially provided with a screw rod for connecting with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com