Wavy laminated microchannel refrigerator

A technology of micro-channel and refrigerator, which is applied in the direction of refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of limited temperature drop of refrigerators and cannot meet the needs of deep and low temperatures, and achieve enhanced bypass flow and simplified testing. The effect of the file structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

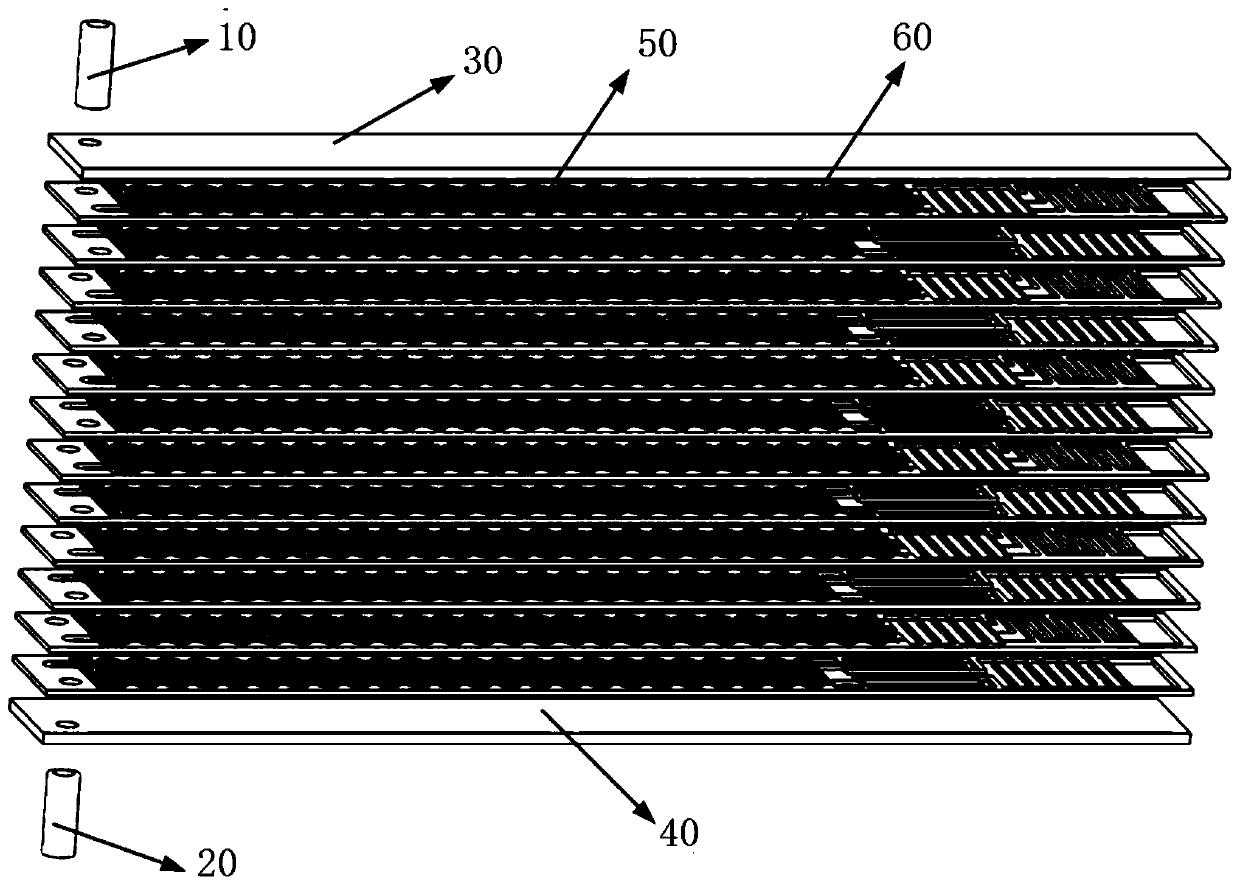

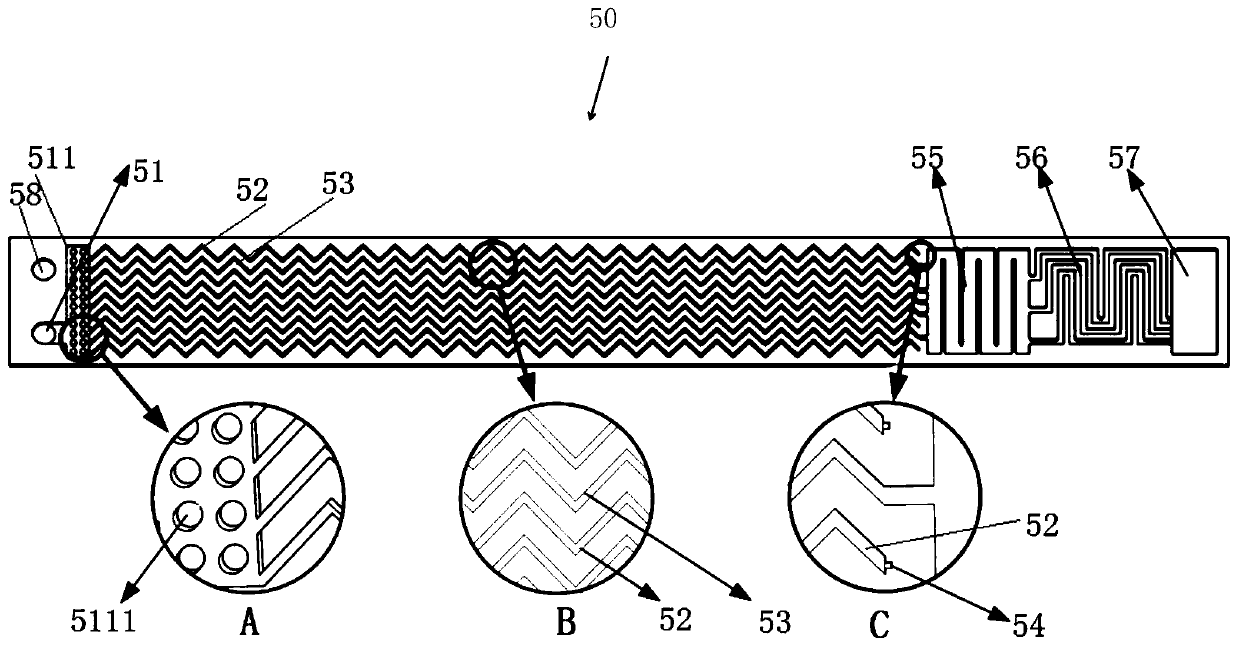

[0029] The two-stage wave-shaped laminated micro-channel refrigerator provided by the present invention is composed of a plurality of high-pressure and low-pressure channel plates arranged in a staggered arrangement, and connected by an atomic diffusion fusion welding process. On the outermost layer of the plate, two upper and lower cover plates with a certain thickness are arranged to support and stabilize the entire test piece. Among them, the high and low pressure plates both contain two-stage channel structures and pre-cooling parts separated from each other.

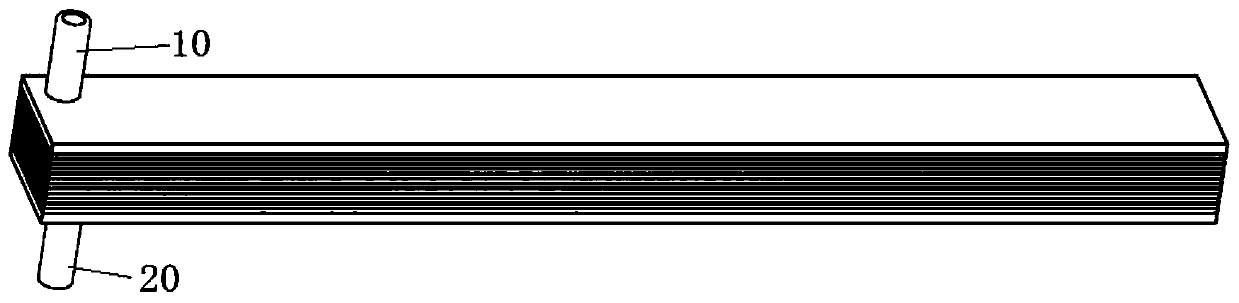

[0030] Such as figure 1 , 2 As shown, the two-stage wave-shaped laminated microchannel refrigerator includes an upper cover plate 30 stacked in sequence, a plurality of high-pressure channel plates 50 and a plurality of low-pressure channel plates 60 stacked up and down staggeredly, a lower cover plate 40 and an air intake pipe 10 , outlet pipe 20.

[0031] The upper cover plate 30 is respectively provided with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com