Structure for improving stability of stationary blade of gas turbine

A gas turbine, stability technology, applied to components of pumping devices for elastic fluids, liquid fuel engines, stators, etc., can solve problems such as backflow enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

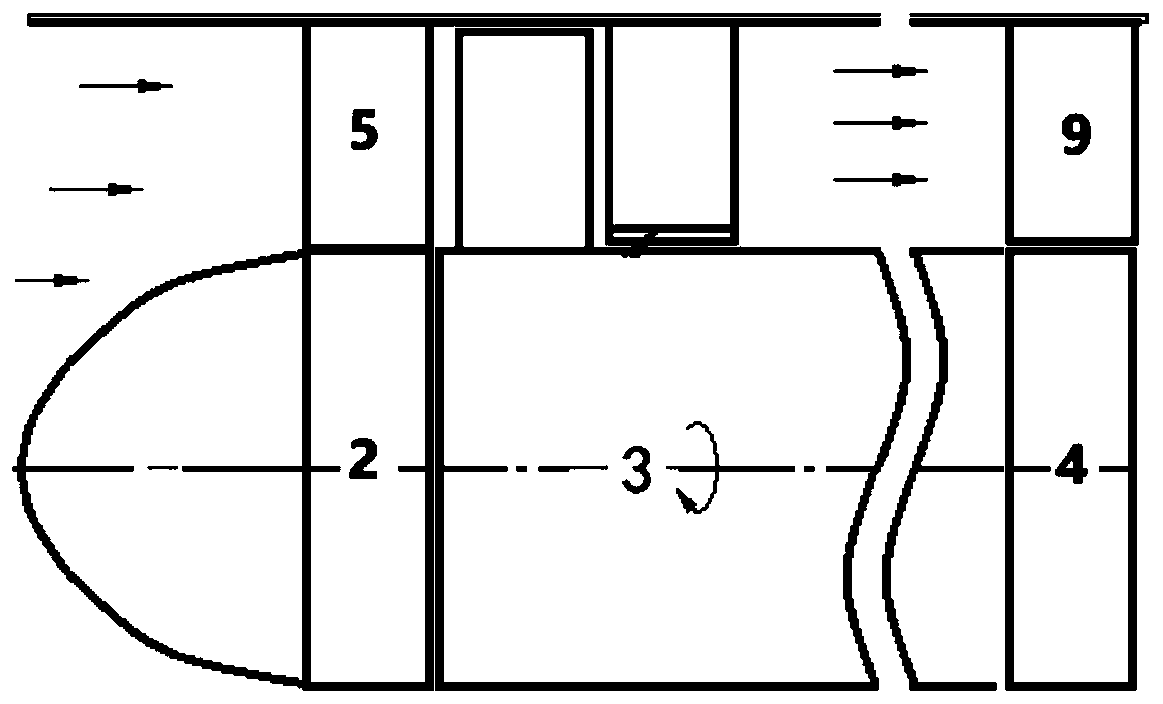

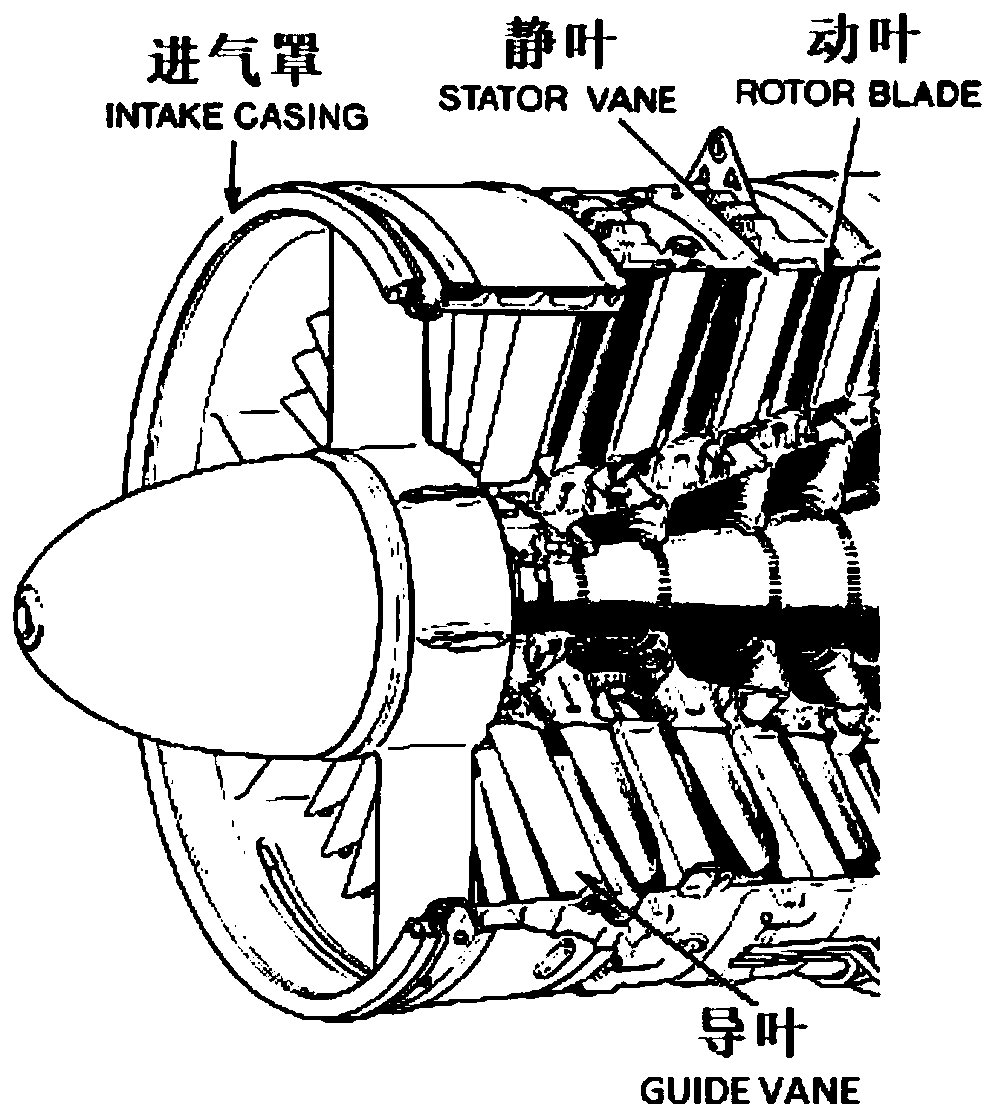

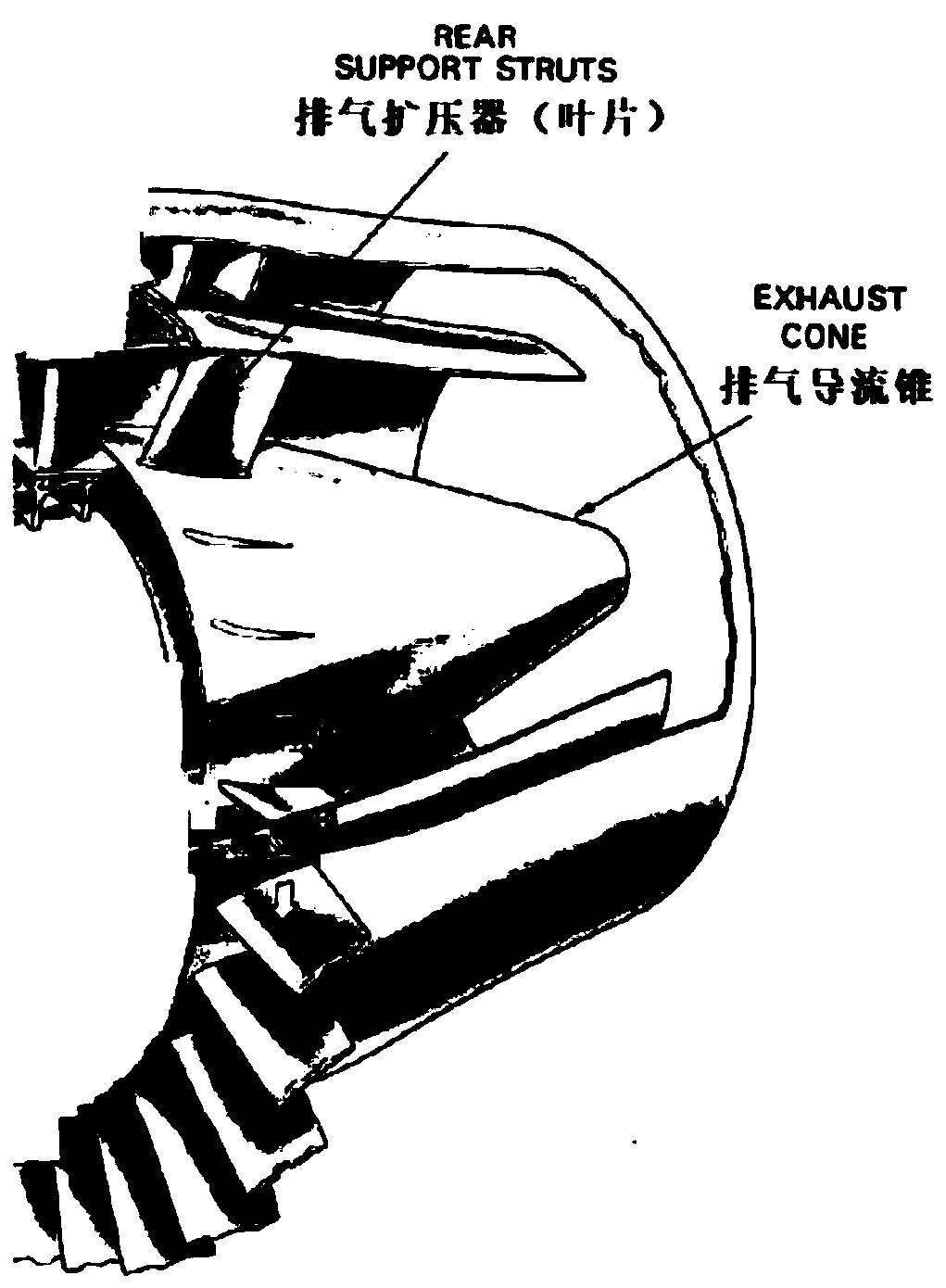

[0020] Such as Figure 4 As shown, a structure for improving the stability of a gas turbine vane includes a vane and a rotating inner cylinder, and the vane is a guide vane or a diffuser vane or a swirler vane. The fluid in the inner ring of the stator blade is in direct contact with the rotating inner cylinder, so that the fluid vortex in the boundary layer of the inner ring of the stator blade is subjected to Ekman suction, the vortex is strengthened, and the volume is reduced, which can reduce the influence of the vortex on the downstream. The vane enters the axial flow compressor or vane pump or gas turbine and exits through the outlet diffuser. The high-density fluid in the direction of the outer diameter of the stator blade flows to the inner ring, maintains and expands the effective flow area of the stator blade, and prevents the backflow of the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com