Ultra-high accuracy temperature measurement method

A precision measurement, ultra-high technology, applied in thermometers, measuring devices, heat measurement, etc., can solve the problem that the accuracy and resolution cannot be improved beyond the ultra-high index, product consistency is not high, open-loop control technology uncertainty drift, etc. problem, to achieve the effect of improving accuracy and resolution and realizing ultra-high precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

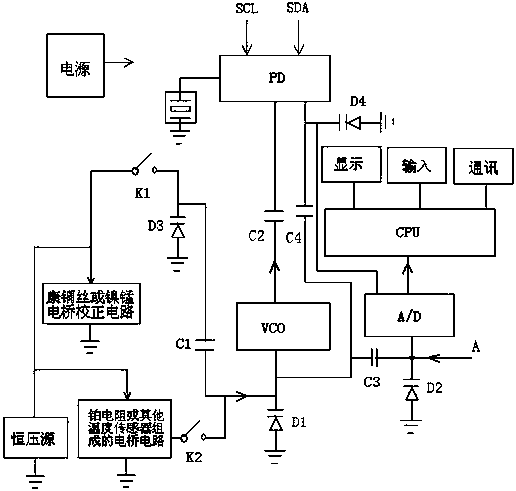

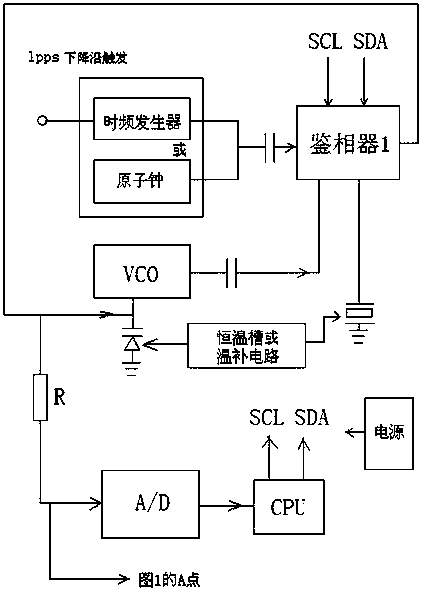

[0015] Such as figure 1 As shown, the temperature measuring instrument is based on temperature sensor, VCO and varactor diodes D1~D4, phase detector PD, A / D analog-to-digital converter, processor CPU, and can also include correction circuit, constant voltage source, relative Measurement circuits and peripheral circuits of processors. The working process is as follows: first, through the bridge circuit composed of platinum resistance or other temperature sensing heads and constant voltage sources, the temperature signal reflected by the temperature sensing head is converted into a certain millivolt level voltage signal through the switch K 2 Added to the varactor D 1 On, and converted into a certain value of capacitance F1, this capacitance F1 at the same time through the capacitance C 3 Connect the varactor diode D 2 The fitting capacitance value F2, and then through the capacitance C 1 Connect the varactor diode D 3 Form the fitting capacitance value F3, the phase-lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com