Conductivity Online Pulp Concentration Measurement Method

A technology of pulp concentration and measurement method, applied in the direction of material resistance, etc., can solve the problems of poor connection, loss of movement force, waste and other problems, and achieve the effect of eliminating influence, effective shielding, and ensuring stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

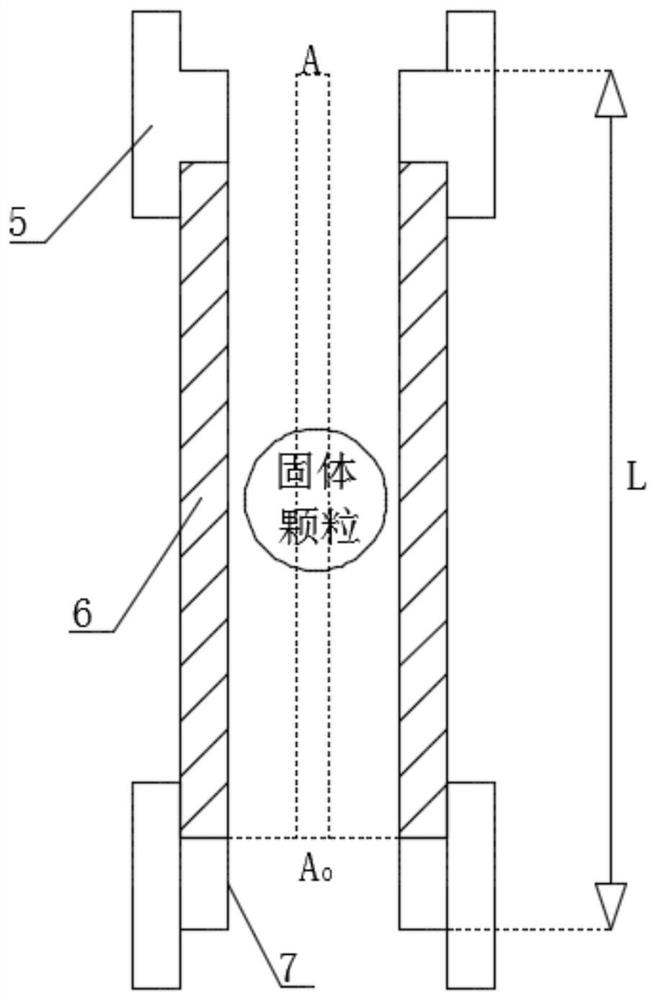

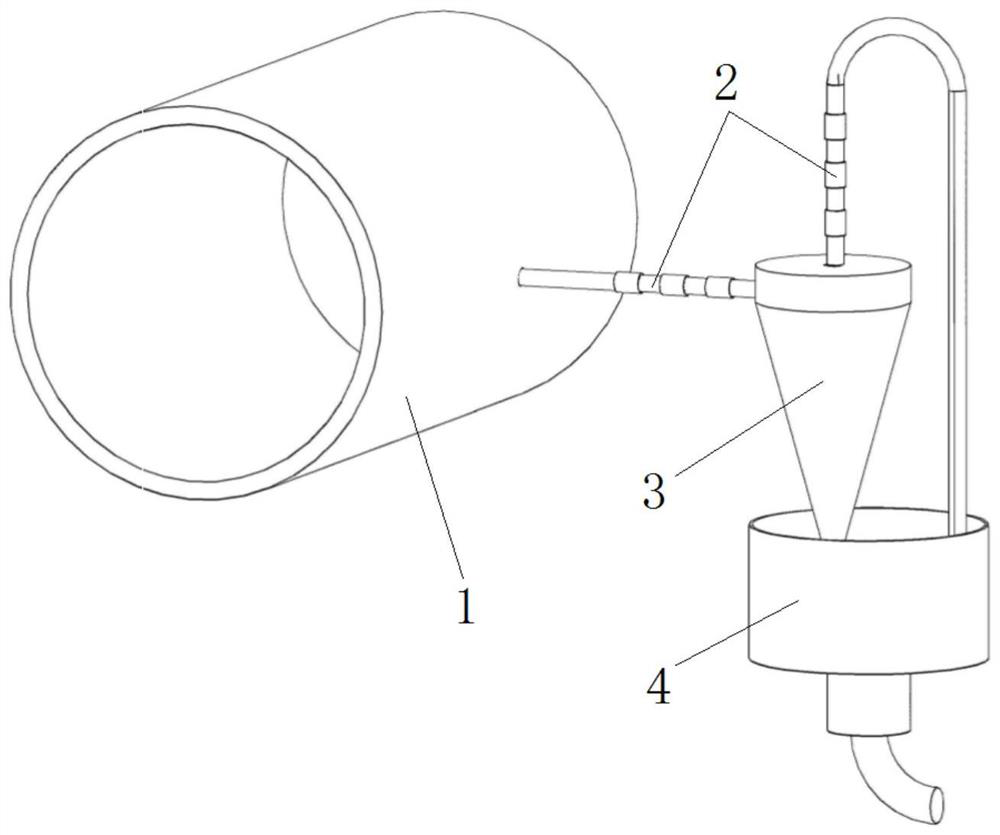

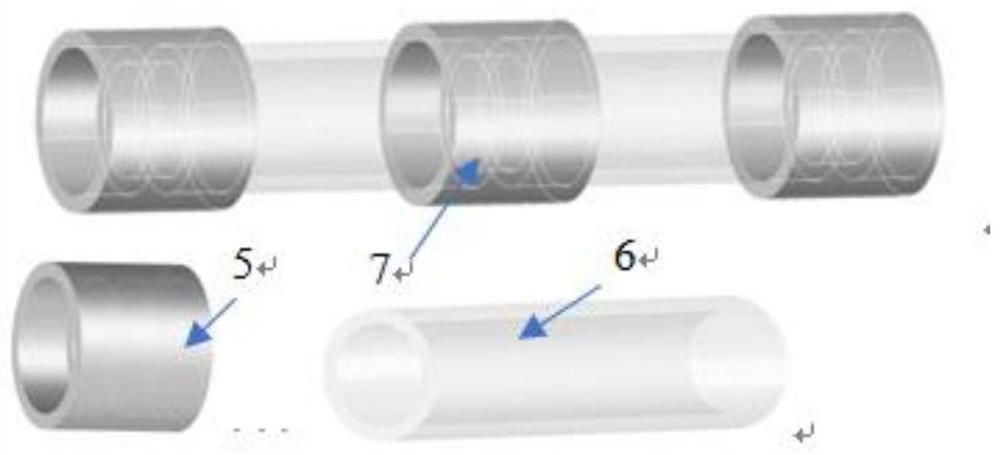

[0072] This embodiment provides a pulp concentration meter, which will be described in detail below.

[0073] 1. Applicable conditions

[0074] Any instrument has its own applicable conditions, and the same is true for this pulp concentration meter. Here we mainly talk about the applicable requirements for the measurement object (pulp). The specific conditions of the pulp are as follows:

[0075] (1) The pulp pressure is greater than or equal to 0.5Kg / cm 2 (gauge pressure); the minimum temperature of the slurry cannot be lower than the freezing point, and the maximum temperature is less than 100°C.

[0076] (2) The pulp must be Newtonian fluid. Must not be a non-Newtonian fluid, such as a Bingham fluid. Usually, the concentration of transported pulp is controlled (when the concentration is too high, water should be replenished appropriately) so that its mass concentration is less than 70% to 60% to meet the requirements. The greater the ore density, the higher the mass conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com