Solid-liquid mixed aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor, solid-liquid mixing technology, used in electrolytic capacitors, capacitors, capacitor parts and other directions, can solve problems such as insufficient capacity, capacity decay, failure, etc., to achieve reduced temperature resistance, high capacity extraction rate, and increased capacity elicited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

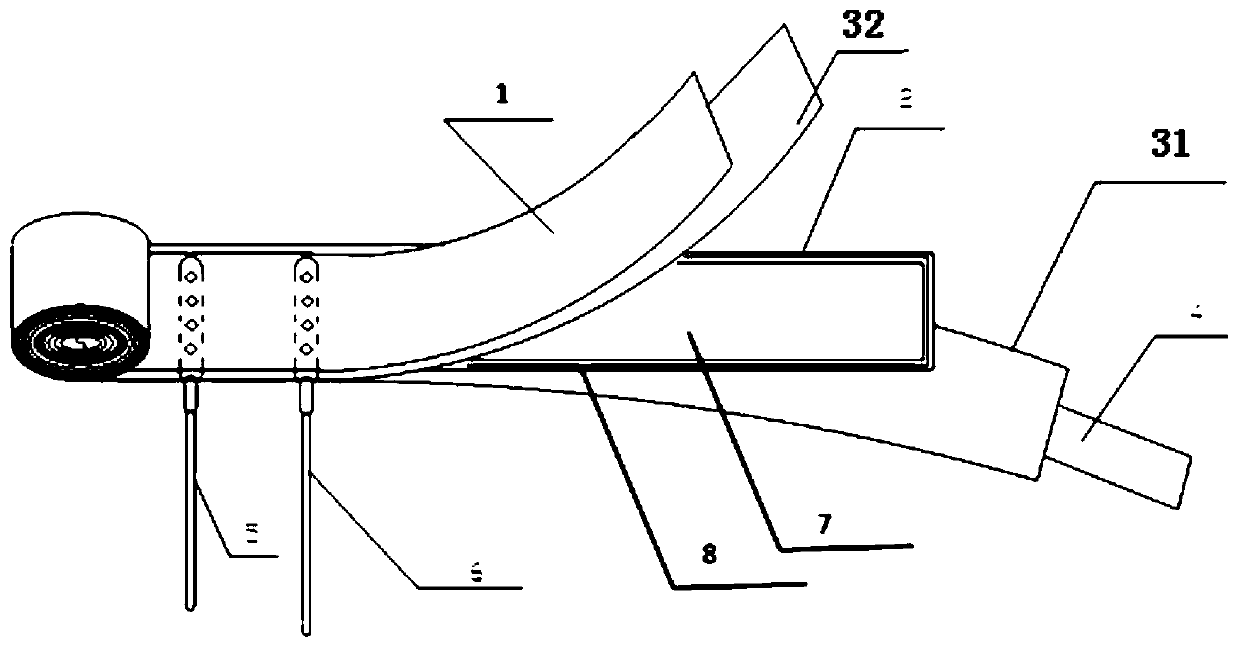

[0041] combine figure 1 , a solid-liquid mixed aluminum electrolytic capacitor provided by the present invention includes an aluminum shell and a core body arranged in the aluminum shell, and the core body includes electrolytic paper-31, negative electrode carbon foil 2, The electrolytic paper 2 32 and the cylindrical structure formed by winding the anodized foil 1, one end of the positive guide pin 6 is connected with the anodized foil 1, one end of the negative guide pin 5 is connected with the negative carbon foil 2, the positive guide pin 6 and The other end of the negative electrode guide pin 5 is exposed outside the aluminum shell, wherein the electrolytic paper one 31, the negative electrode carbon foil 2, the electrolytic paper two 32, and the anodized foil 1 are all provided with conductive polymers on the surface, the said The electrolytic paper 1 or separator 1, the negative carbon foil 2, the electrolytic paper 2 or separator 2, and the conductive polymer on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com