Preparation method of a low-voltage large-capacity polymer chip laminated aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and polymer sheets, which is applied in the manufacture of electrolytic capacitors, electrolytic capacitors, solid electrolytic capacitors, etc., can solve the problems of unsatisfactory, limited improvement effect, large difference in hole structure of the formed foil oxide layer, etc. Achieve the effect of increasing the capacity of finished products, considerable economic benefits, and increasing the rate of capacity extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

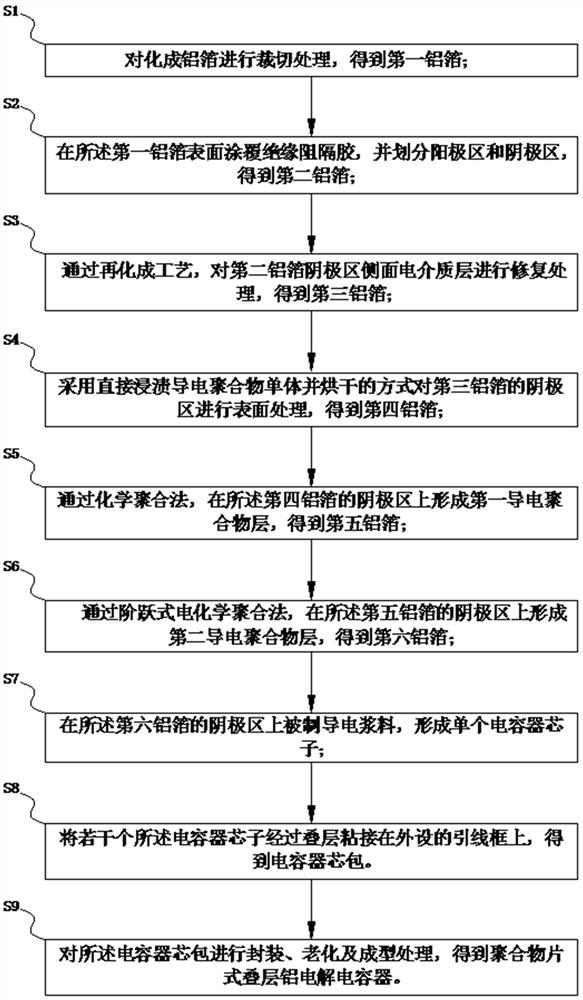

[0033] see Figure 1-2 , the present invention provides a technical solution: specifically, a method for preparing a low-voltage large-capacity polymer chip laminated aluminum electrolytic capacitor, which is characterized in that it includes the following steps:

[0034] S1. Cutting the chemically formed aluminum foil to obtain the first aluminum foil;

[0035] S2. Coating an insulating barrier glue on the surface of the first aluminum foil, and dividing an anode area and a cathode area to obtain a second aluminum foil;

[0036] S3. Repairing the dielectric layer on the side of the cathode region of the second aluminum foil through a re-chemical conversion process to obtain a third aluminum foil;

[0037] S4. Surface-treating the cathode region of the third aluminum foil by directly impregnating the conductive polymer monomer and drying to obtain the fourth aluminum foil;

[0038] S5. Forming a first conductive polymer layer on the cathode region of the fourth aluminum foil...

Embodiment 1

[0056] S1. Cutting the 2.6VF chemically formed aluminum foil to obtain the first aluminum foil;

[0057]S2. Coating an insulating barrier glue on the surface of the first aluminum foil, and dividing an anode area and a cathode area to obtain a second aluminum foil;

[0058] S3. Repairing the dielectric layer on the side of the cathode region of the second aluminum foil through a re-chemical conversion process to obtain a third aluminum foil;

[0059] S4. Surface treatment is carried out on the cathode area of the third aluminum foil by directly impregnating the conductive polymer monomer and drying to obtain the fourth aluminum foil. The specific method is as follows:

[0060] Immerse the cathode area of the third aluminum foil into thiophene monomer, the purity of thiophene is greater than 99.5%, and the immersion time is 55s; after the immersion, perform drying treatment, the drying temperature is 35°C, and the drying time is 3min;

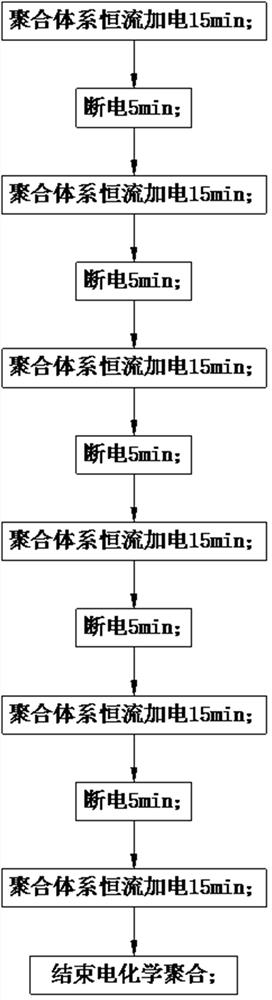

[0061] S5. Form a first conductive p...

Embodiment 2

[0071] The difference from Example 1 is:

[0072] S4. Surface treatment is carried out on the cathode area of the third aluminum foil by directly impregnating the conductive polymer monomer and drying to obtain the fourth aluminum foil. The specific method is as follows:

[0073] Immerse the cathode area of the third aluminum foil into thiophene monomer, the purity of thiophene is greater than 99.5%, and the immersion time is 65s; after the immersion, perform drying treatment, the drying temperature is 45°C, and the drying time is 6min;

[0074] S5. Form a first conductive polymer layer on the cathode region of the fourth aluminum foil by chemical polymerization to obtain a fifth aluminum foil, the specific method is as follows:

[0075] S51. Immerse the cathode region of the fourth aluminum foil into an aqueous solution of iron p-toluenesulfonate, take it out and dry it to obtain the first intermediate aluminum foil, wherein the proportion of iron p-toluenesulfonate is 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com