Positive pole mixed powder for producing positive pole of solid electrolytic capacitor

A solid electrolysis and capacitor technology, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems affecting the product capacity extraction rate and the large capacitance change rate, and achieve the advantages of reduced friction, increased capacity extraction rate, and reduced dead holes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

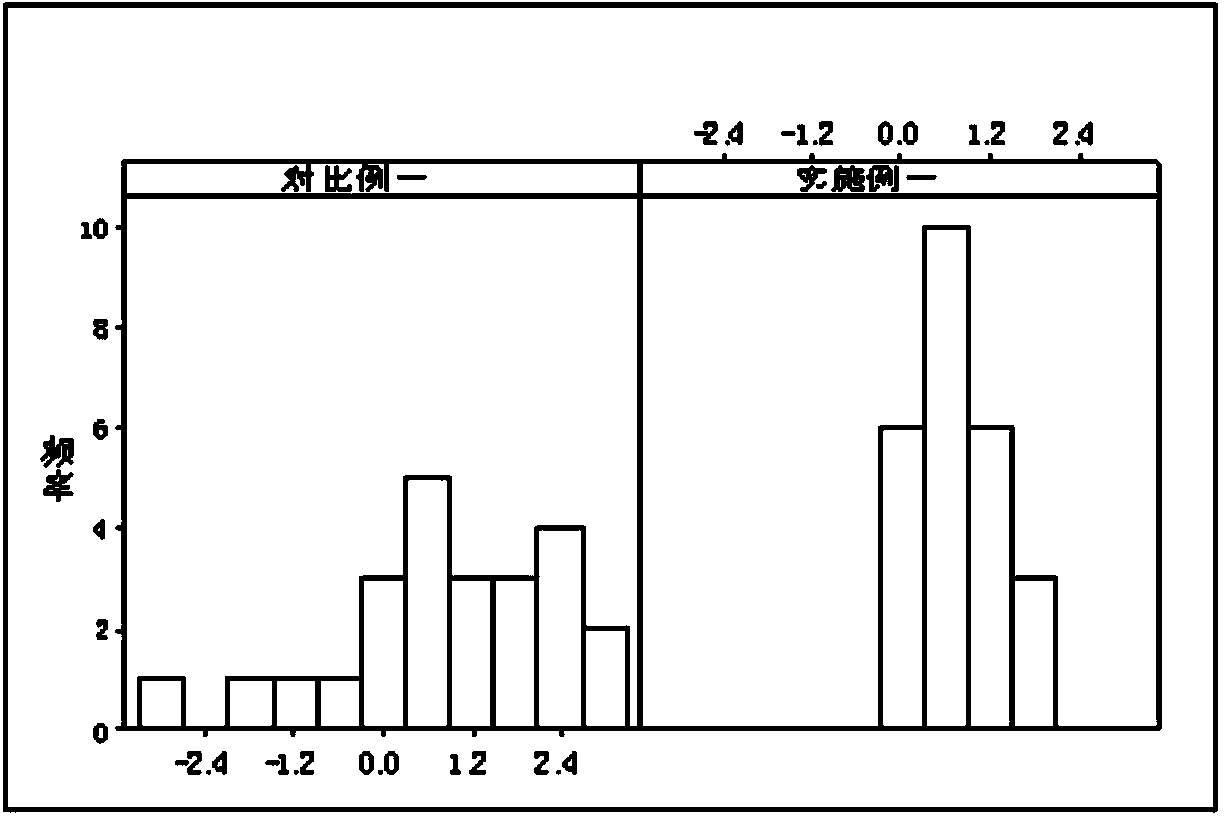

Examples

Embodiment 1

[0020] Add dimethyl sulfone and butyl acetate to 120k (μF V / g) tantalum powder and mix evenly. The mass ratio of the three is: dimethyl sulfone: butyl acetate: tantalum powder = 3:30:50, Using a conventional method in this field, the anode mixed powder was stirred at 60° C. for 2 hours to prepare a pellet with a nominal capacity of 220 μF.

[0021] With the mixed anode powder of this example, after dewaxing by conventional methods in this field, the carbon content is <100ppm (measured by ICP analyzer, Perkin Elmer Optima), and the oxygen content is close to the inherent oxygen content of the original tantalum powder (analyzed by oxygen content instrument, measured by American LECO).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com