Method for processing workpiece

A technology for processed objects and processing methods, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve problems such as wafer defects and cracks, and achieve the effect of suppressing poor processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

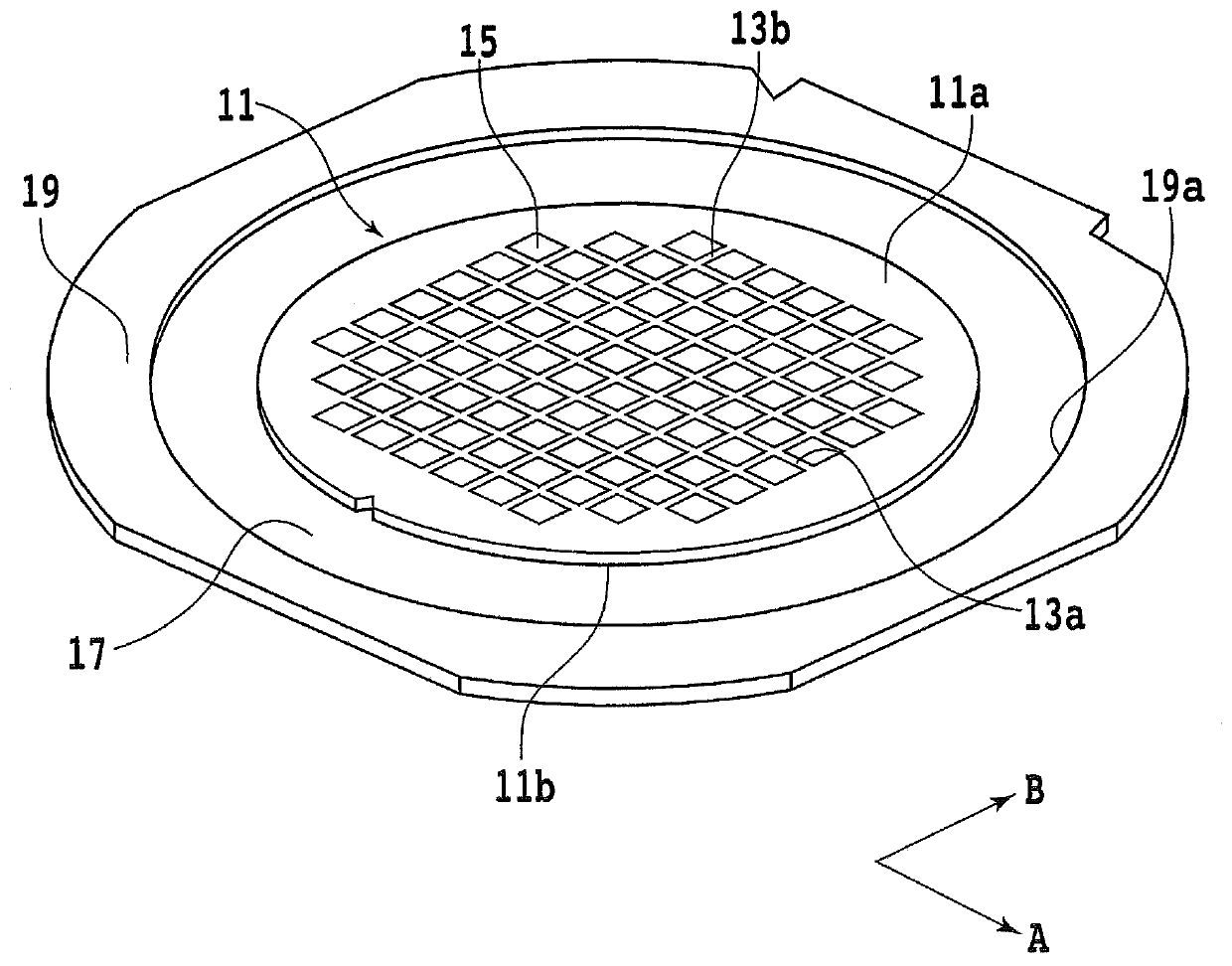

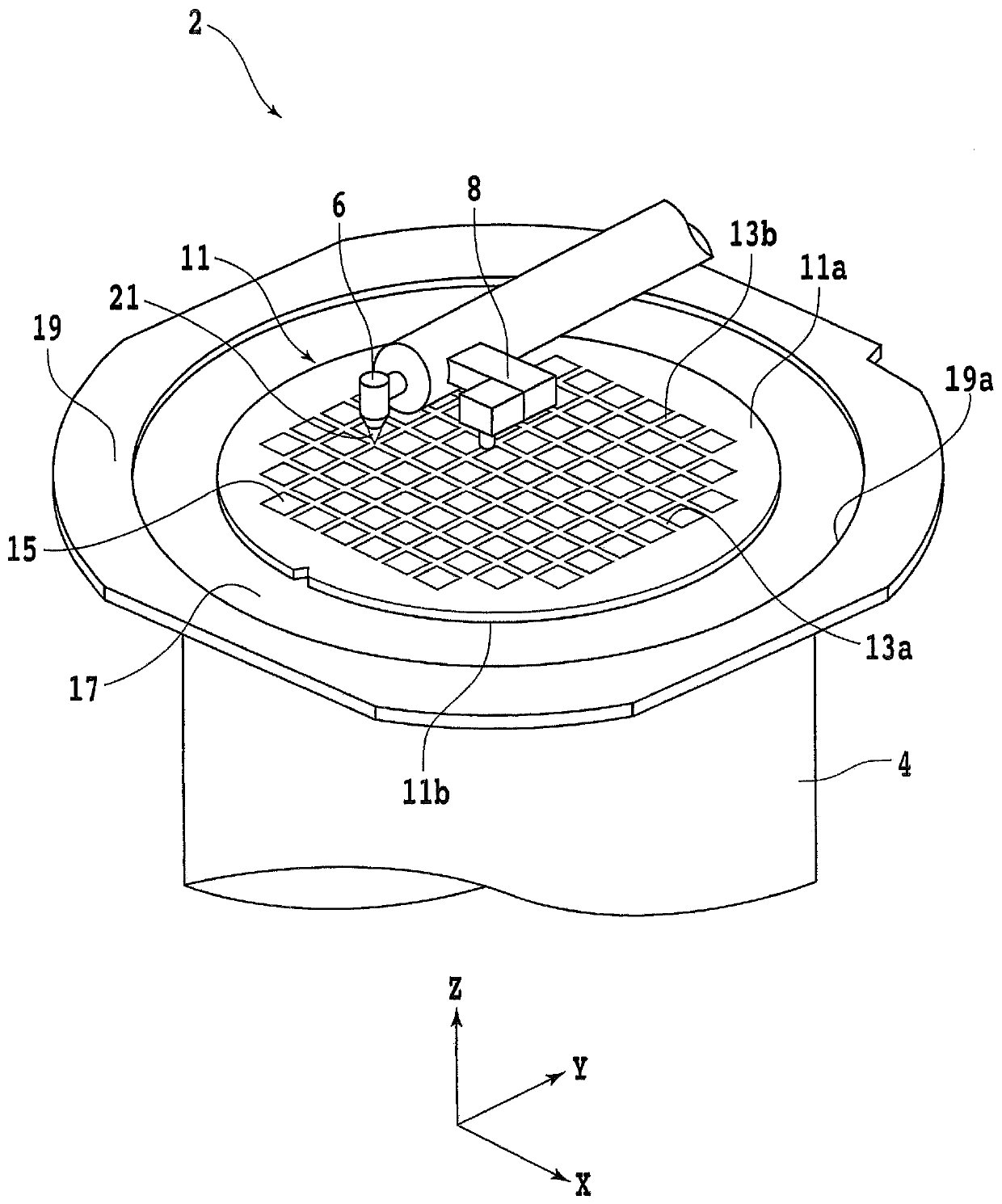

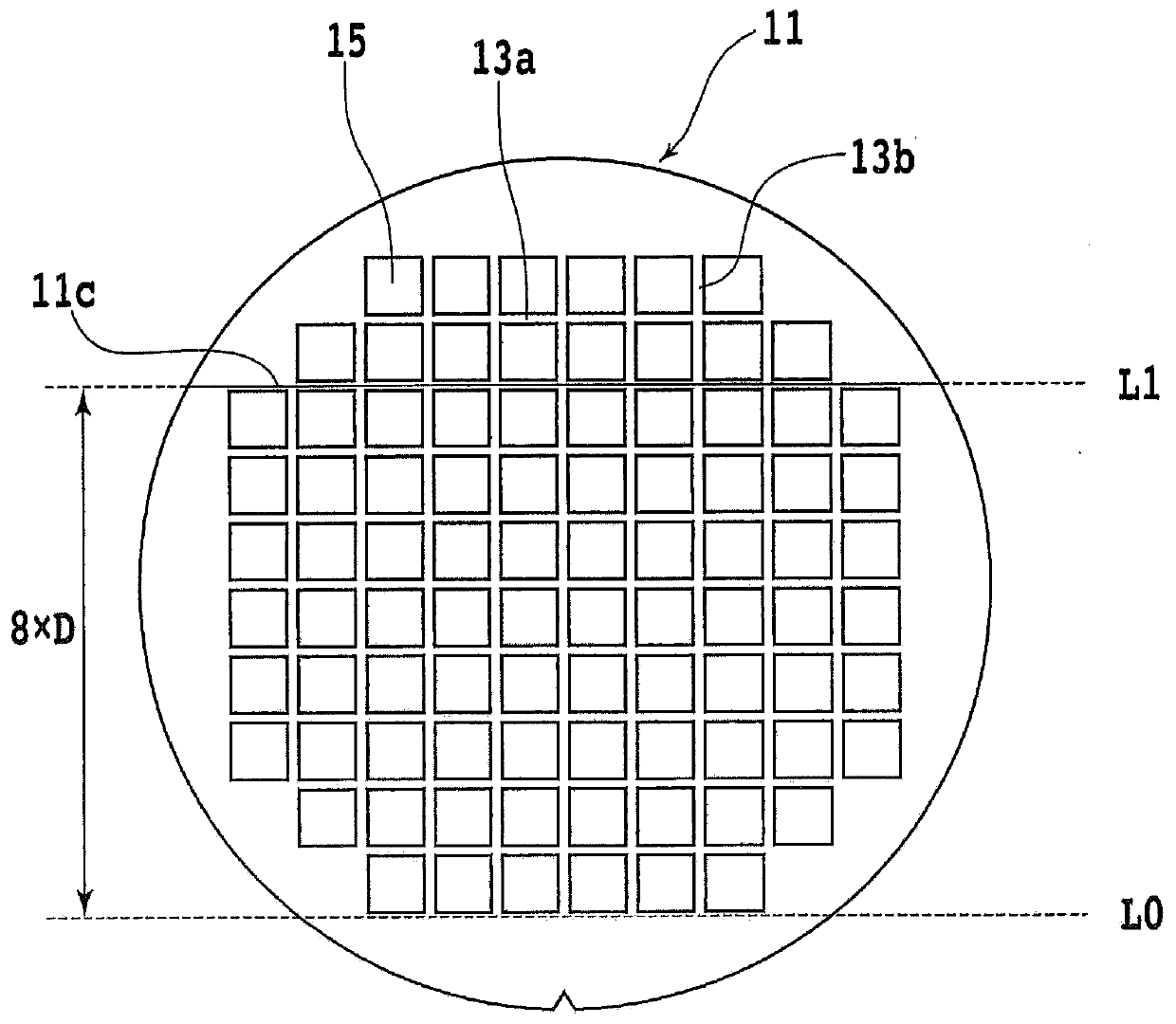

[0022] When irradiating a laser beam to form processing marks such as grooves on a plate-shaped workpiece, for example, when the workpiece is processed sequentially from the end, chipping, cracks, etc. are likely to occur on the workpiece bad. It is presumed that this phenomenon is because: when one of the two regions divided by the processing marks formed by irradiation of laser beams as a boundary is sufficiently small, there will be a gap between the two regions due to irradiation of laser beams. The heat generated during the time produces a large temperature difference.

[0023] That is, it is considered that this problem can be solved if the heat generated during irradiation of the laser beam is conducted in the same manner in the two regions divided by the processing mark as the boundary. Therefore, in the present invention, after forming a plurality of processing marks on the workpiece and dividing them into regions of a certain size, a laser beam is irradiated to a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com