Steel member, hot-rolled steel sheet for said steel member and production methods therefor

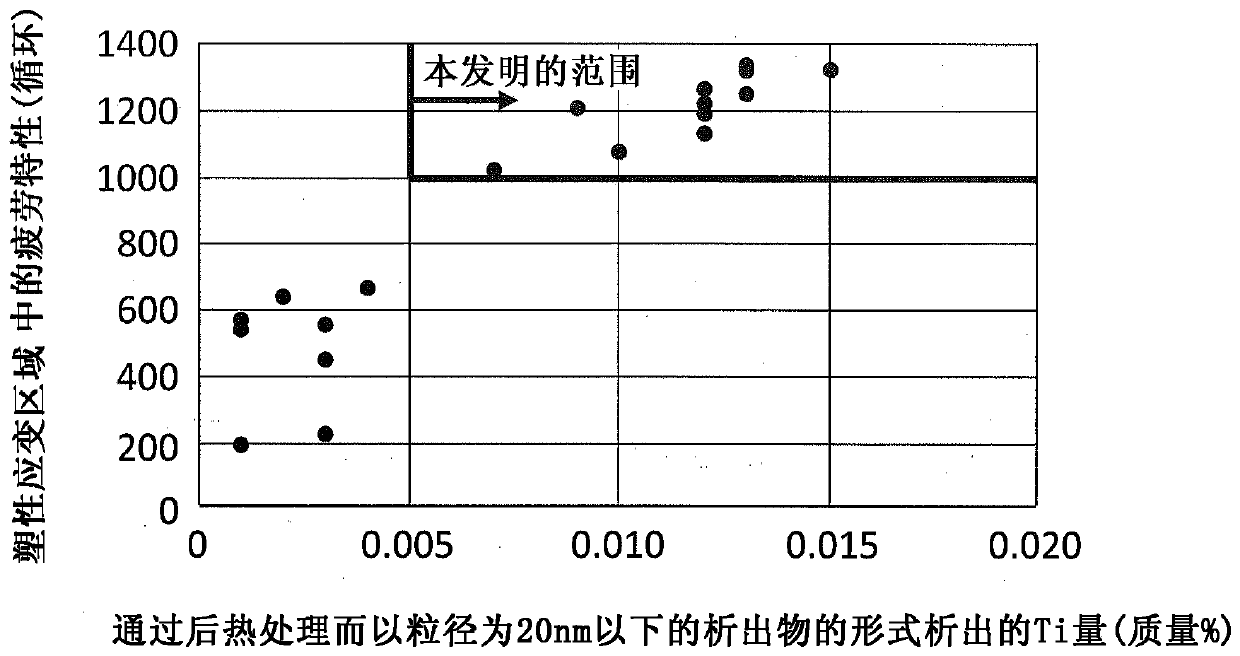

A technology of hot-rolled steel plate and manufacturing method, which is applied in the field of improvement of fatigue life, hot-rolled steel plate, and welded steel pipe for coiled tubing, and can solve the problems that the fatigue resistance characteristics of the plastic strain area cannot be obtained, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

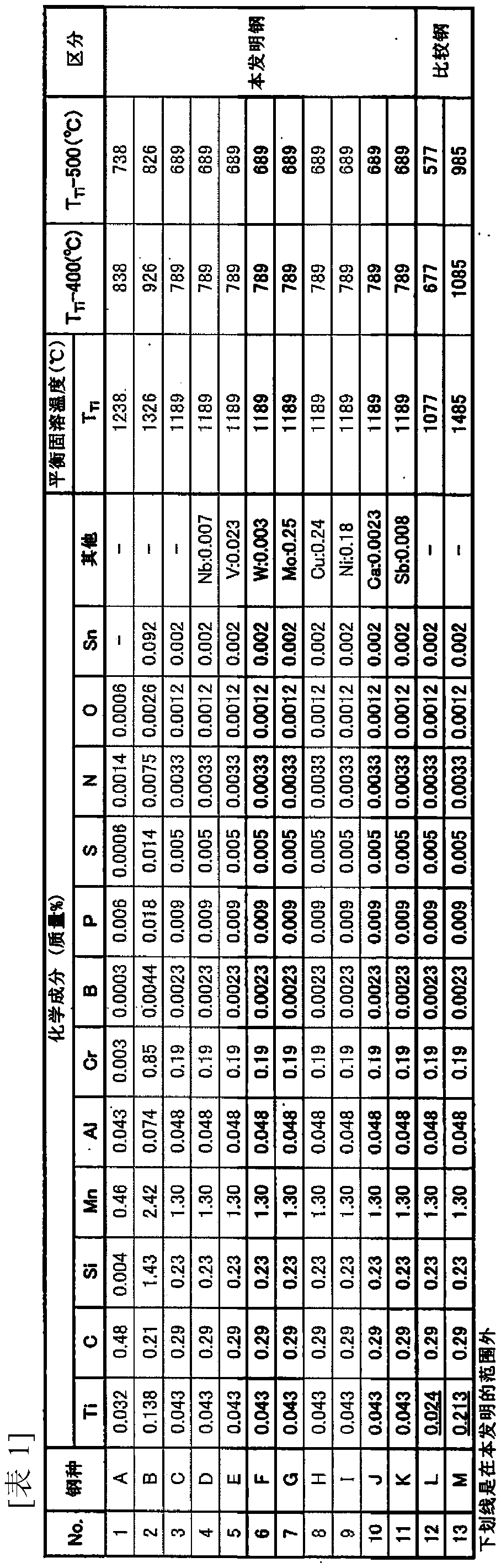

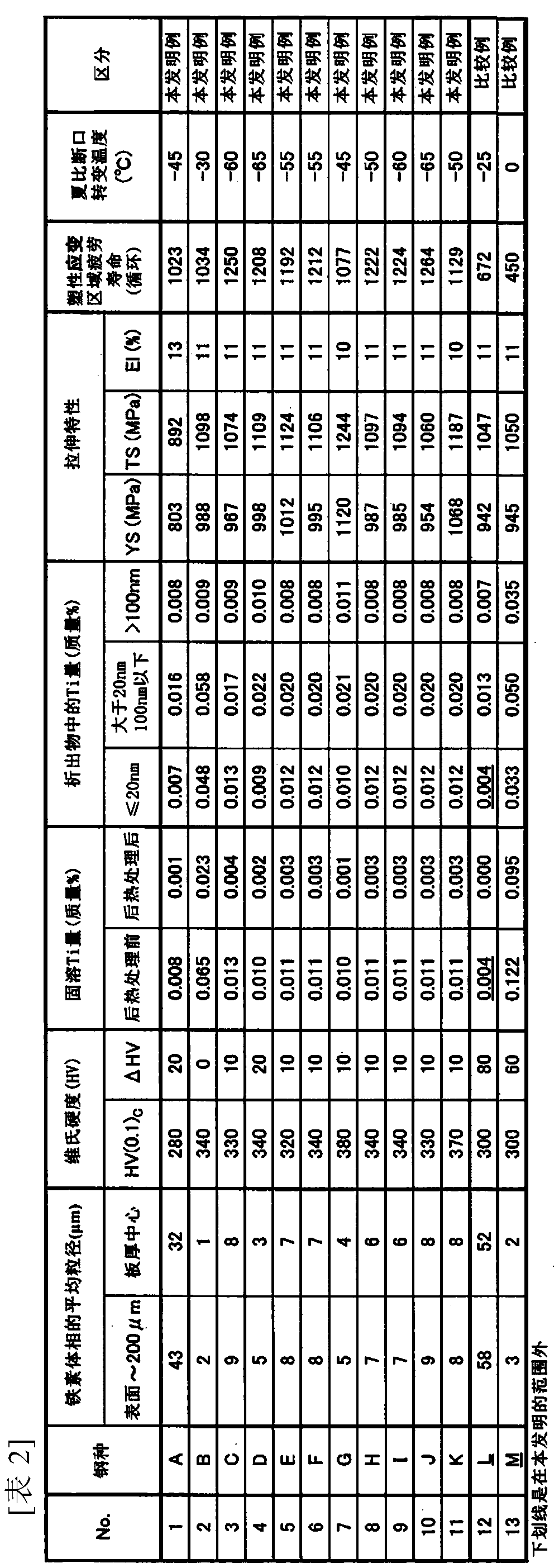

[0121] The slabs with the compositions (steel grades C to L) shown in Table 1 were extracted from the heating furnace when the surface temperature of the slab was about 1220°C and the center temperature of the slab was about 1210°C, and the final rolling reduction was 91%. The finishing temperature in the central part of the width of the coil is about 860°C, and the lowest finish rolling temperature in the width direction of the coil is about 850°C. Ti -400°C to T Ti Cool at an average cooling rate of about 20°C / s in the temperature range of -500°C, and hot-roll at a coiling temperature of about 560°C to make raw hot-rolled steel sheets (thickness: about 5mm, front and rear ends) The plate thickness is about 10% thicker than the central part of the length) (No. 3-12).

[0122] In addition, the steel slab with the composition (steel type A) shown in Table 1 was extracted from the heating furnace when the surface temperature of the slab was about 1250°C and the temperature of t...

Embodiment 2

[0142] Steel slabs having the composition of steel grades A, B, and C shown in Table 1 were subjected to hot rolling under the conditions shown in Table 3 to produce raw hot-rolled steel sheets (thickness: about 5 mm, the thickness of the front and rear ends relative to about 10% thicker in the center of the length). Next, after pickling these hot-rolled steel sheets as raw materials, they are slitting into predetermined width dimensions and continuously formed to form open tubes. The open tubes are resistance-welded by high-frequency resistance welding to obtain a width reduction ratio of 4% A welded steel pipe having an outer diameter φ of 50.8 mm and a wall thickness of about 5 mm. The entire welded steel pipe was continuously subjected to high-frequency heating, and heat treatment was performed under the conditions shown in Table 3. Test pieces were cut out from these welded steel pipes, and subjected to a microstructure observation test, a quantitative test of precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com