Rod milling cylinder for rod mill, cylinder cover and installation method of rod milling cylinder

A rod mill and rod mill technology, which is applied in the field of mining machinery, can solve the problems of dislocation and looseness of the cover plate, injury to the hands and feet of the operator, and difficulty in removing the cover plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

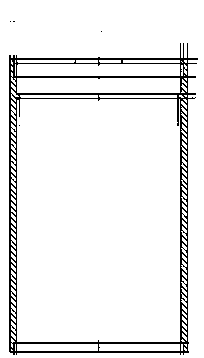

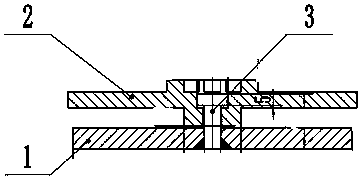

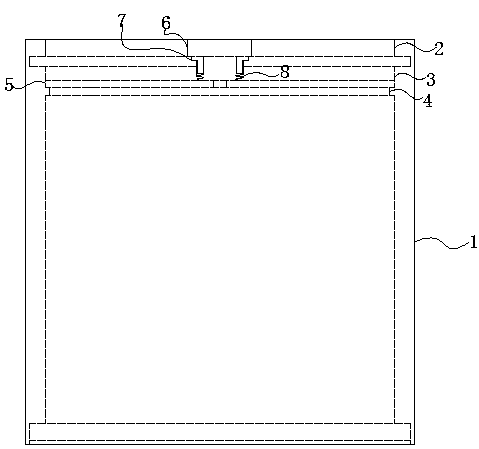

[0025] Embodiment 1: as Figure 3-5 As shown, the rod mill cylinder used for the rod mill includes a cylinder body 1 and a cylinder cover. The top of the cylinder body is provided with a circular spigot 2, and the circular spigot is provided with two diameters symmetrically with respect to the center. To the notch, the first boss 3 and the second boss 4 which are continuously distributed along the axial direction of the cylinder are provided under the circular spigot in the cylinder, and the cylinder cover includes a conformal fit on the second boss. The circular cover plate 5 on the top and the arc-shaped cover plate 6 that can conformally fit in two radial notches, the arc-shaped cover plate and the circular cover plate are concentric, and the arc-shaped cover plate passes through the rigidity in turn. The connecting piece 7 and the spring 8 are affixed to the circular cover plate.

[0026] The arc-shaped cover plate referred to here refers to the shape with a rectangle in ...

Embodiment 2

[0028] Preferred embodiment 2: as Figure 6 As shown, a cylinder 9 is affixed to the bottom surface of the arc-shaped cover plate, and a hollow cylinder 10 is affixed to the upper surface of the circular cover plate corresponding to the cylinder. The inner diameter of the cylinder is suitable, and the cylinder and the hollow cylinder are distributed at intervals under normal conditions. When the arc-shaped cover is pressed, the spring is compressed, and the cylinder will be inserted into the hollow cylinder. After testing, it was found that the arc-shaped cover plate in Example 1 would apply a radial torsion force to the spring when it rotated, and this would cause great damage to the spring. In order to avoid damage to the spring and shorten the service life of the cover, even the spring The cylinder cover cannot be taken out after being damaged, so the applicant thought that the spring should not bear the torsion force generated when the arc-shaped cover plate rotates, and h...

Embodiment 3

[0029]Preferred embodiment 3: The difference from preferred embodiment 2 is that a hollow cylinder is affixed to the bottom surface of the arc-shaped cover plate, and a cylinder is affixed to the upper surface of the circular cover plate corresponding to the hollow cylinder. The outer diameter of the cylinder matches the inner diameter of the hollow cylinder. Under normal conditions, the cylinder and the hollow cylinder are spaced apart. When the arc-shaped cover is pressed, the spring is compressed, and the cylinder will be inserted into the hollow cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com