RIC finger sleeve underwater medium hydraulic shearing device

A technology of shearing device and finger casing, which is applied in the field of reactor pressure vessel maintenance, can solve the problems of not being able to return to the initial position completely, foreign matter falling into the core, and affecting the safety of the core, so as to solve the problem of safety and the reset of the movable blade problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

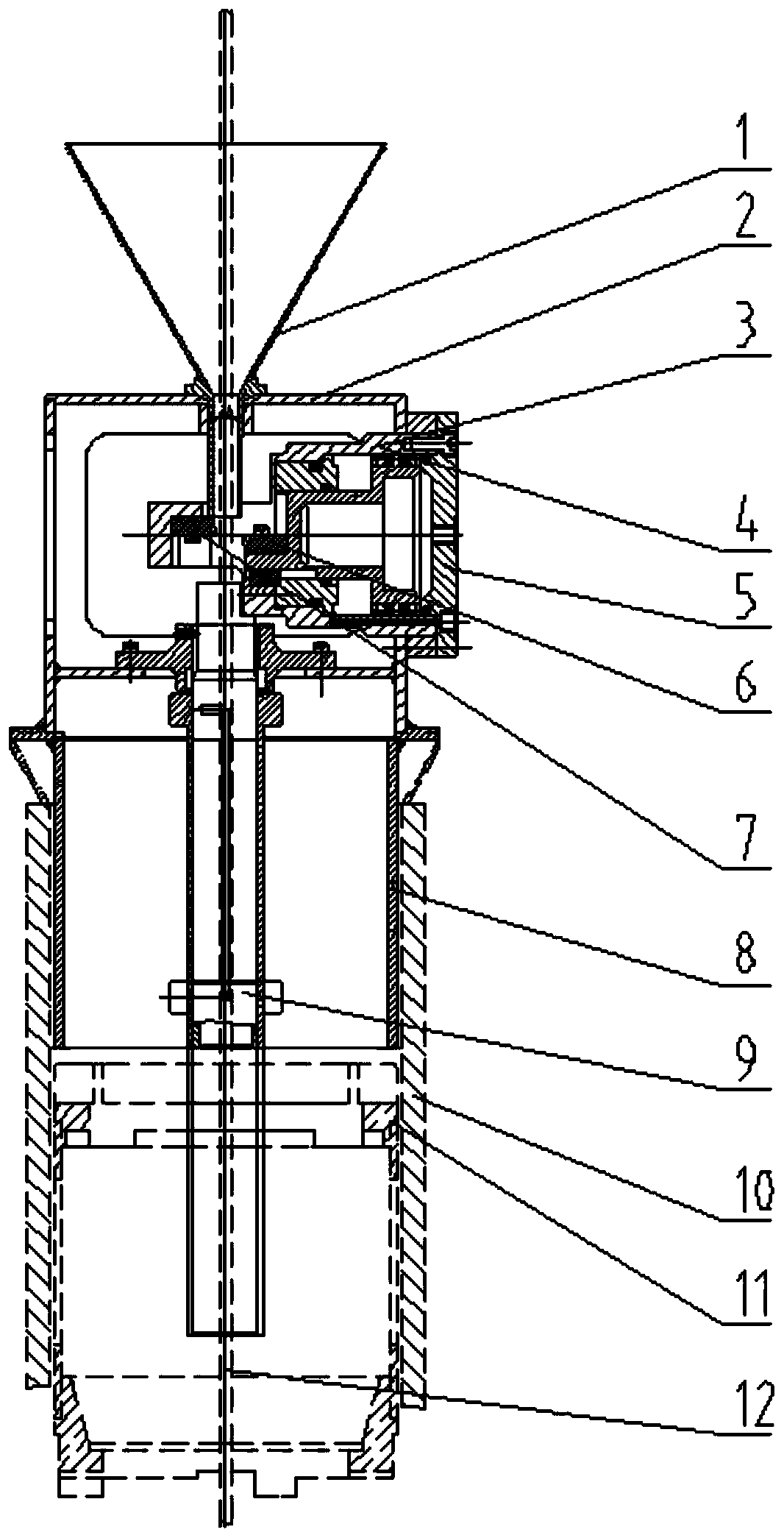

[0013] A kind of RIC refers to casing underwater water medium hydraulic shearing device, comprising a conical guide cylinder 1, a shear box 2, a square positioning sleeve 8 and a lower guide sleeve 9, wherein the conical guide cylinder 1 has a funnel-shaped structure, and its Installed on the upper end of the shear box 2, it guides the finger sleeve 12 put into the tapered guide cylinder 1, so that the finger sleeve 12 can enter the shear box 2 in the vertical direction; it is fixed inside the shear box 2 A shearing cylinder is installed to shear the finger sleeve 12 inserted into the shear box 2 through the tapered guide cylinder 1, wherein the shearing cylinder includes a cylinder body 3, a piston 4 and a shearing blade, and the cylinder body 3 is integrally fixed inside the shell of the shear box 2, and an oil channel is provided on the cylinder body 3, and the oil channel opening of the cover is at the front end of the cylinder body 3; the piston 4 is installed inside the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com