Curtain Roma hole distance adjusting table plate

A hole spacing adjustment and platen technology, which is applied in metal processing and other directions, can solve the problems of increasing equipment footprint, difficulty in controlling precision, and affecting hole opening accuracy, so as to protect equipment, reduce equipment footprint, and reduce overall size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

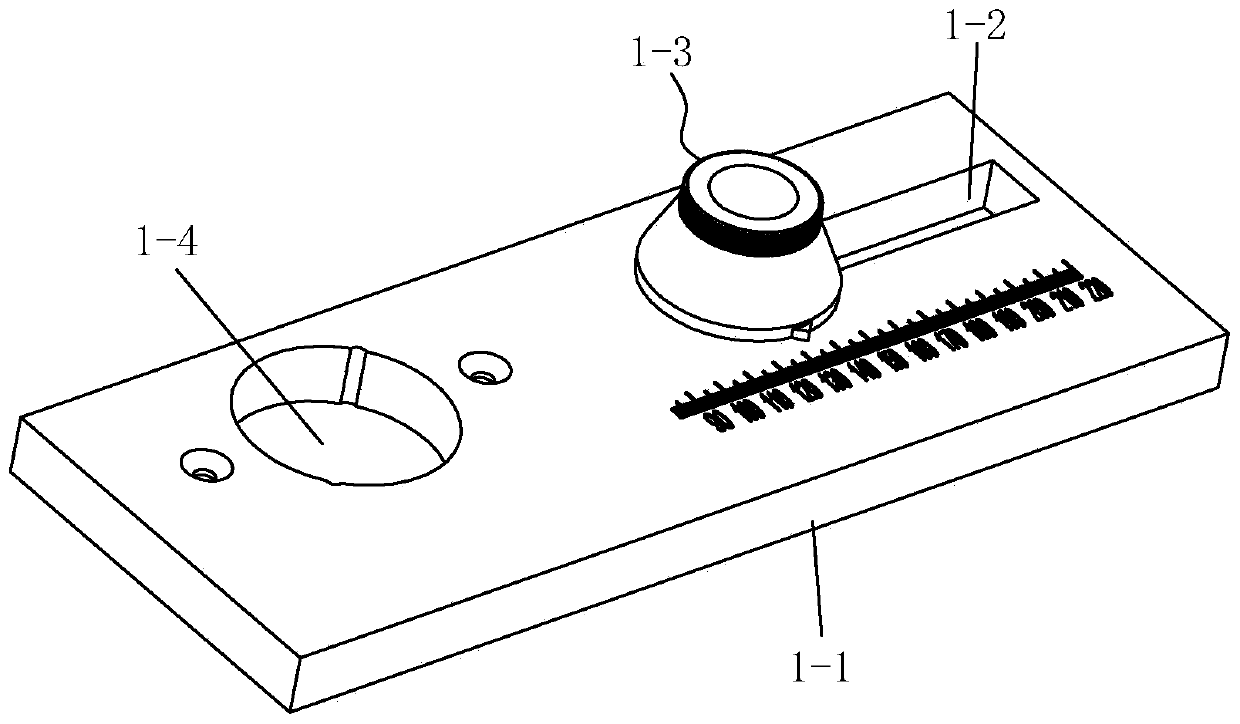

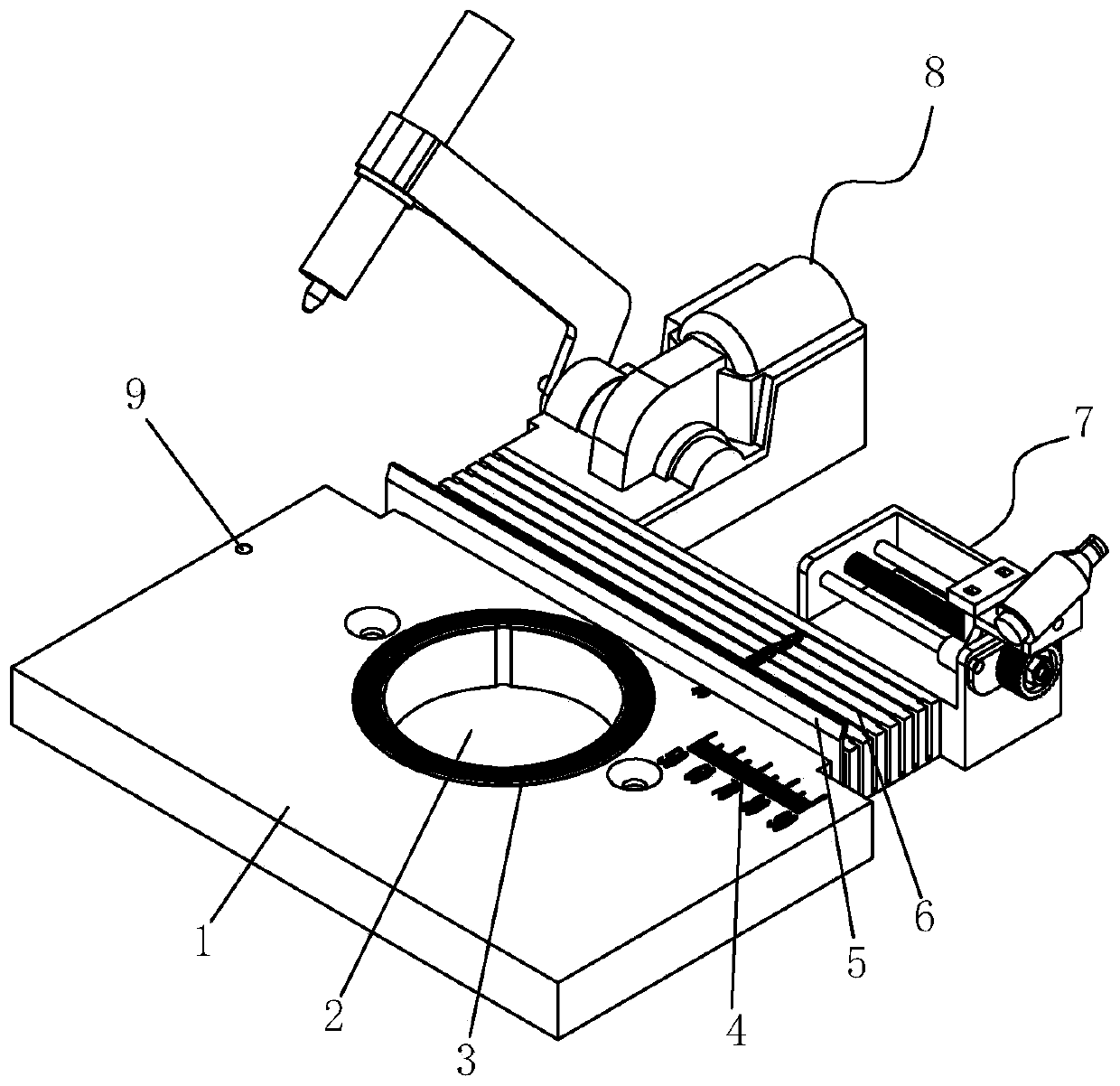

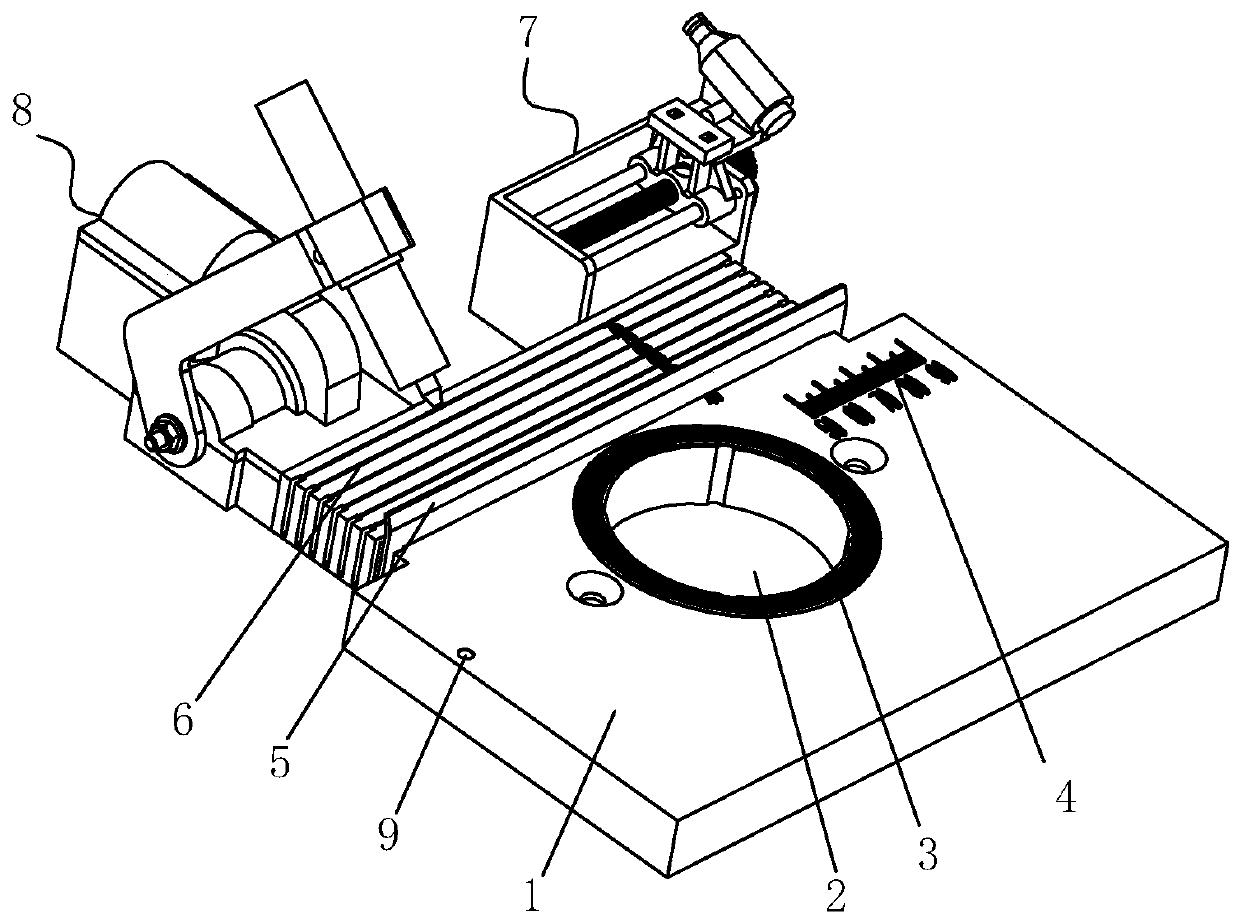

[0031] Such as Figure 2 to Figure 6 As shown, a curtain Roman hole pitch adjustment platen of the present invention includes a platen main body 1, a cutter hole 2 penetrating through the upper and lower end surfaces of the platen main body 1 is opened in the middle of the platen main body 1, and the cutter hole 2 Anti-slip lines 3 are provided on the upper surface of the table main body 1 outside the circumference.

[0032] The upper side of the table main body 1 is connected with a marking assembly 8 and a laser positioning assembly 7, and the marking assembly 8 includes a first base 81, a cover plate 82, a turbine 85, a worm 86, a driving motor 88, and a rotating shaft 87 , a swing arm 83 and a marker pen 84 , the first base 81 is connected to the upper side of the table main body 1 near the left end, and the turbine 85 is positioned on the first base 81 through a rotating shaft 87 . The driving motor 88 is fixedly connected to the first base 81, the worm 86 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com