Installation and working method of silencer spring and locking mechanism in seat slide rail

A technology of locking mechanism and working method, which is applied in movable seats, vehicle seats, transportation and packaging, etc. It can solve the problems of vibrato, troublesome installation, inconvenient installation, etc., and achieves no increase in operating force and convenient installation , the effect of small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

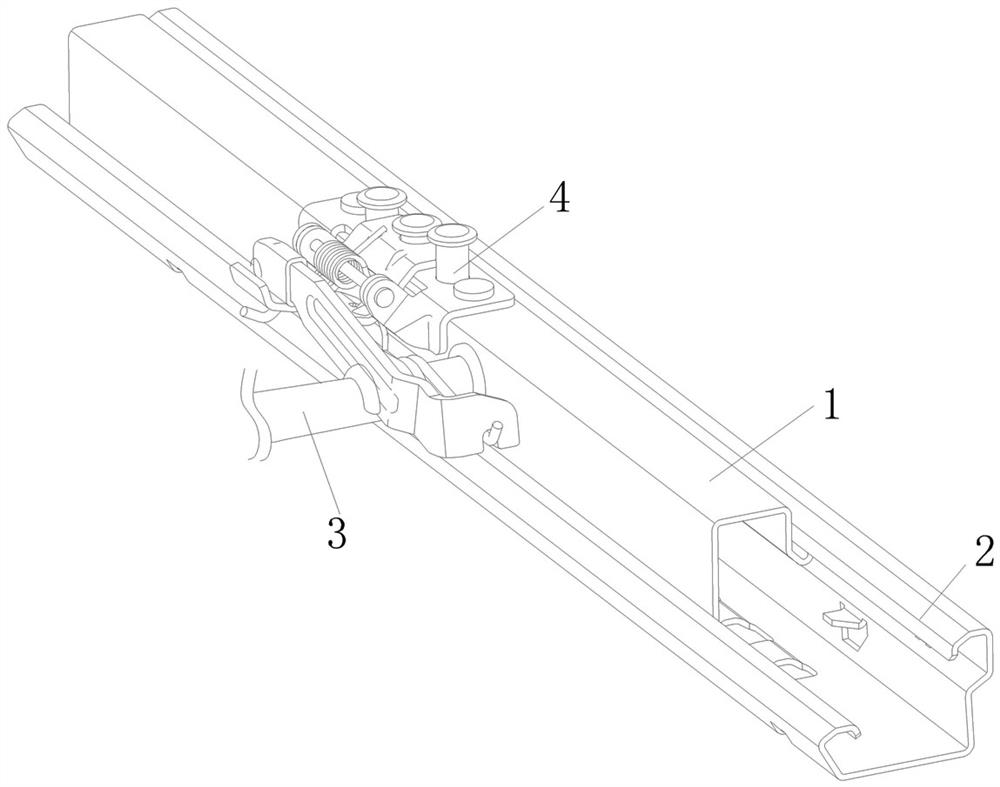

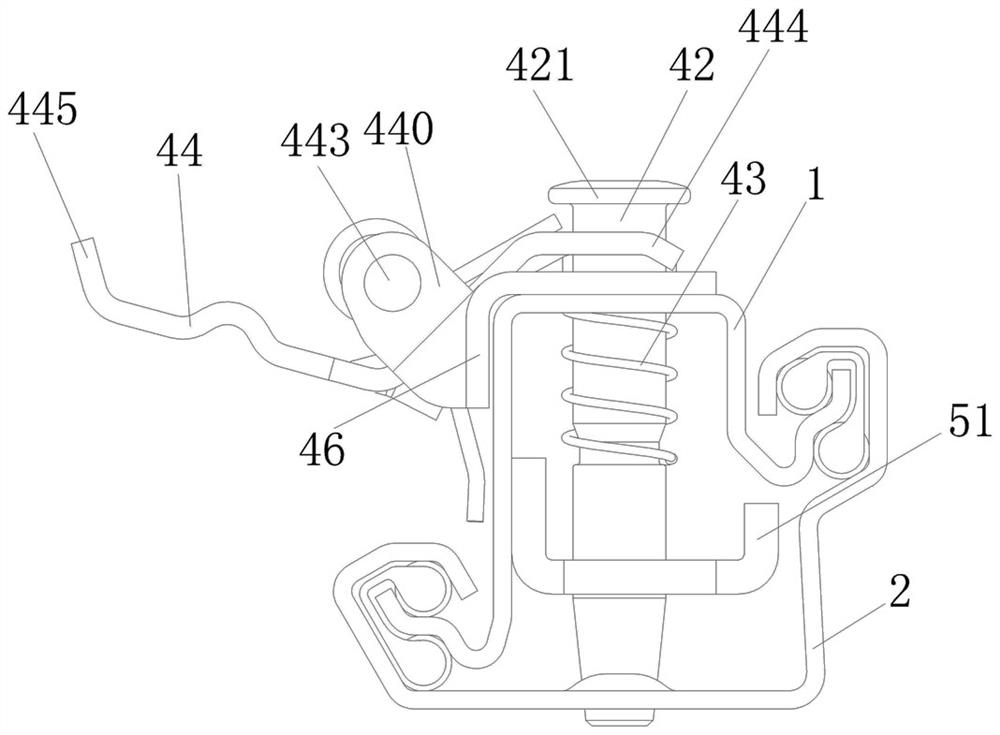

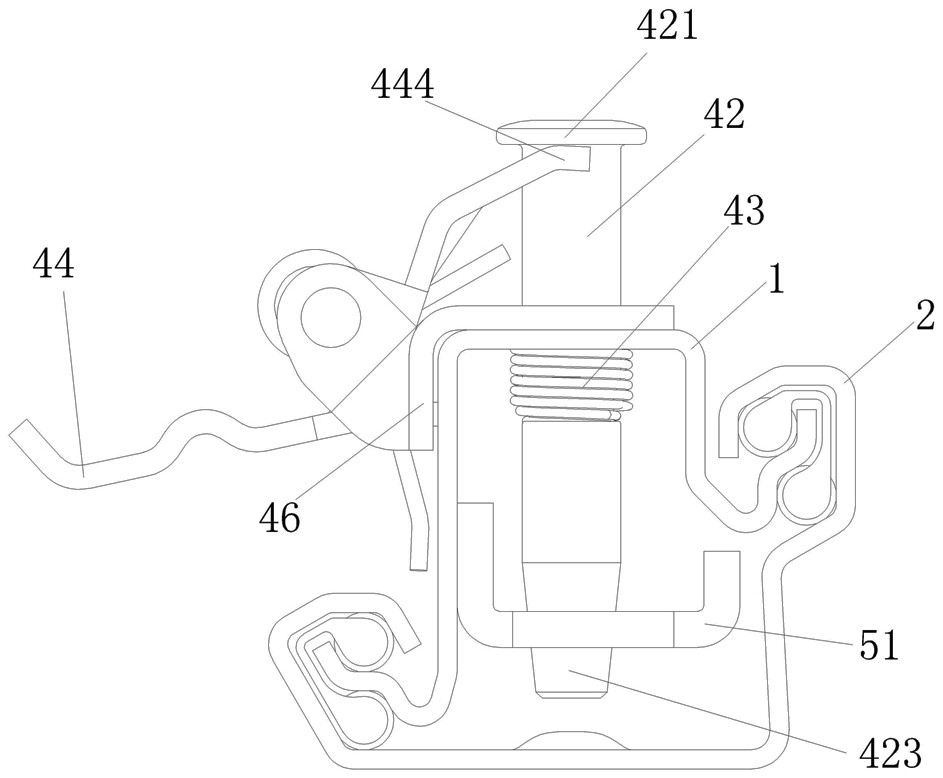

[0039] see Figure 1-Figure 5 , the present invention includes an upper slide rail 1, a lower slide rail 2, a handle assembly 3 and a locking mechanism 4, the upper and lower slide rails 1, 2 are slidably matched, the handle assembly 3 and the locking mechanism 4 are connected to the upper slide rail 1, And the handle assembly 3 cooperates with the locking mechanism 4 .

[0040] Upper slide rail 1 is provided with upper slide rail hole 11 , locking pin hole 12 and upper slide rail rivet hole 14 , and upper slide rail pressure plate bushing 13 is installed;

[0041]In this embodiment, the handle assembly 3 mainly includes a handle shaft 30, a pressure plate 31, a silencer spring 32 and a pressure plate bushing 33, and the pressure plate bushing 33 is fixed on one end of the pressure plate 31; the locking mechanism 4 mainly includes a lock pin guide plate 41, Lock pin 42, locking spring 43, shift fork 44, shift fork groove 441, shift fork return torsion spring 45, bracket plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com