High black vehicle performance polyurethane resin used for leather, and preparation method thereof

A polyurethane resin and color development technology, applied in the fields of synthetic leather materials and synthetic leather polyurethane resin materials, can solve the problems of small molecular weight of dispersant, easy migration, affecting color development effect, etc., and achieve good physical properties, wear resistance and other problems. The effect of improving the performance and improving the color development performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The weight percentage composition of the main polyurethane resin and the auxiliary high black color developing resin is as follows:

[0050]Main body polyurethane resin 70%

[0051] Auxiliary high black color developing resin 30%

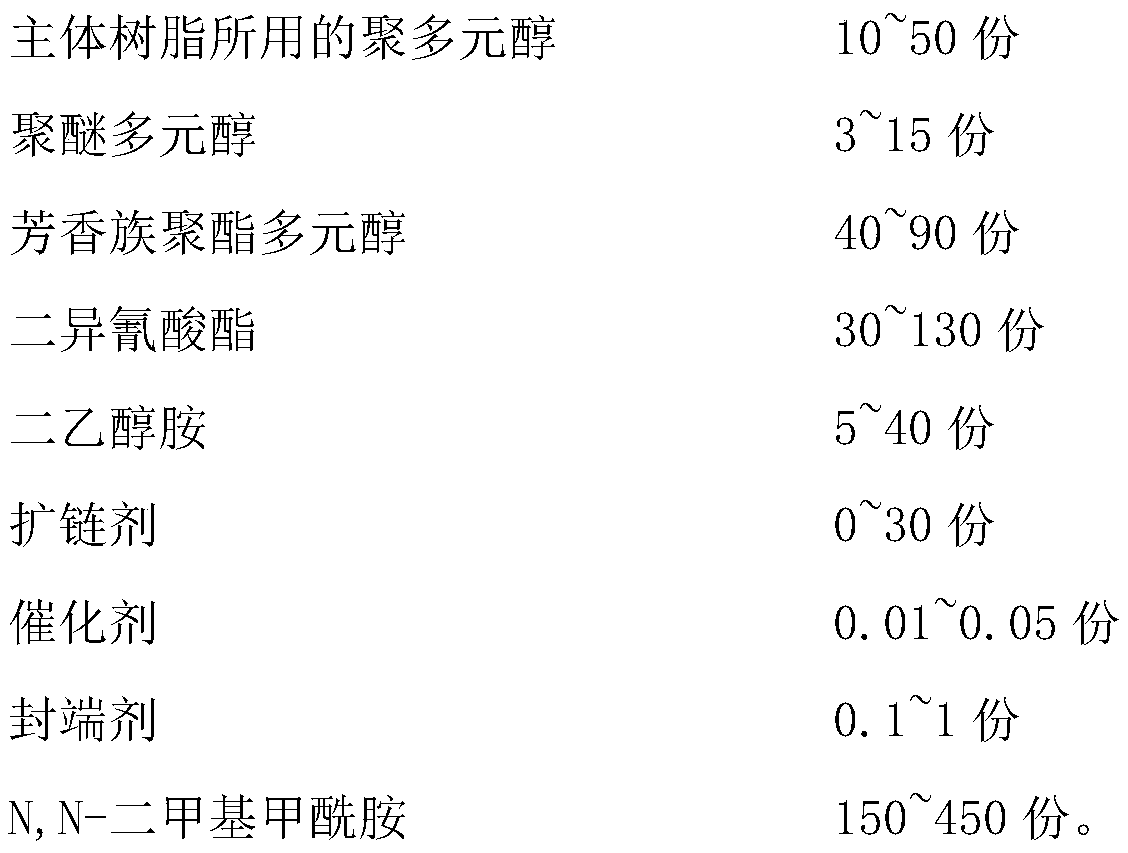

[0052] The main polyurethane resin is mainly prepared from the following raw materials in parts by weight:

[0053]

[0054] The preparation method of main body polyurethane resin, comprises the steps:

[0055] (1) Add polypolyol and chain extender to the reaction vessel, then add solvent accounting for 70% of the total amount, add catalyst, heat up to 50°C after mixing, stir for 20 minutes, and mix well;

[0056] (2) Add diisocyanate accounting for 95% of the total amount, heat up to 60°C, and react for 2 hours;

[0057] (3) Add the remaining solvent and diisocyanate until the viscosity of the reaction solution reaches 112Pa·s / 25°C, add an end-capping agent, and stir for 30 minutes to obtain the main polyurethane resin.

[0058] The a...

Embodiment 2

[0070] The weight percentage composition of the main polyurethane resin and the auxiliary high black color developing resin is as follows:

[0071] Main body polyurethane resin 90%

[0072] Auxiliary high black color developing resin 10%

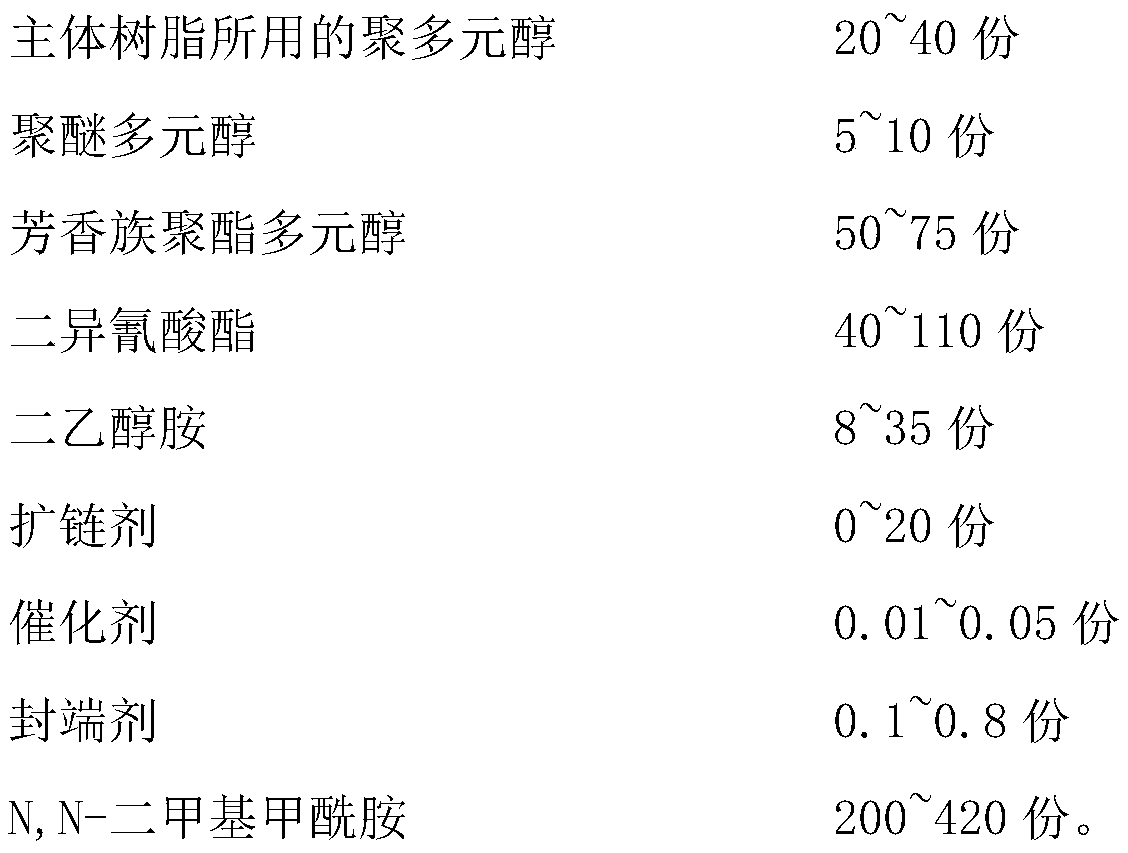

[0073] The main polyurethane resin is mainly prepared from the following raw materials in parts by weight:

[0074]

[0075] The preparation method of main body polyurethane resin, comprises the steps:

[0076] (1) Add polypolyol and chain extender to the reaction vessel, then add solvent accounting for 70% of the total amount, add catalyst, heat up to 50°C after mixing, stir for 30min, and mix well;

[0077] (2) Add diisocyanate accounting for 95% of the total amount, heat up to 60°C, and react for 2 hours;

[0078] (3) Add the remaining solvent and diisocyanate until the viscosity of the reaction solution reaches 106 Pa·s / 25°C, add an end-capping agent, and stir for 30 minutes to obtain the main polyurethane resin.

[0079] The auxi...

Embodiment 3

[0090] The weight percentage composition of the main polyurethane resin and the auxiliary high black color developing resin is as follows:

[0091] Main body polyurethane resin 80%

[0092] Auxiliary high black color developing resin 20%

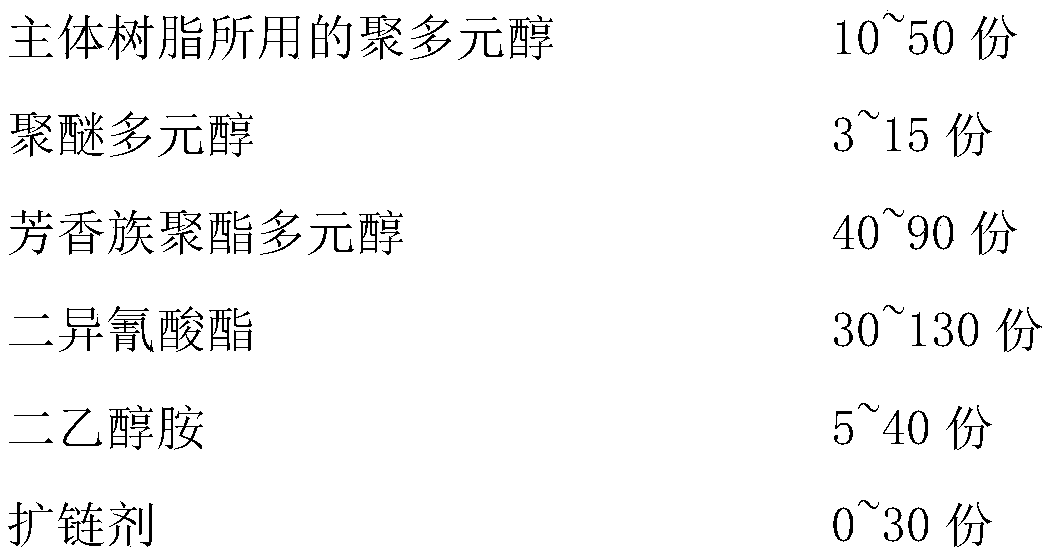

[0093] The main polyurethane resin is mainly prepared from the following raw materials in parts by weight:

[0094]

[0095] The preparation method of main body polyurethane resin, comprises the steps:

[0096] (1) Add polypolyol and chain extender to the reaction vessel, then add solvent accounting for 70% of the total amount, add catalyst, heat up to 50°C after mixing, stir for 20 minutes, and mix well;

[0097] (2) Add diisocyanate accounting for 95% of the total amount, heat up to 70°C, and react for 2 hours;

[0098] (3) Add the remaining solvent and diisocyanate until the viscosity of the reaction solution reaches 109Pa·s / 25°C, add an end-capping agent, and stir for 30 minutes to obtain the main polyurethane resin.

[0099] The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap