Active oil-gas separator

A kind of oil and gas separator, active technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems affecting the normal operation of internal combustion engines, oil loss of internal combustion engine lubricating oil, insufficient internal combustion engine lubricating oil, etc., and achieve good market application prospects , reduce loss, and reduce the overall flow resistance of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

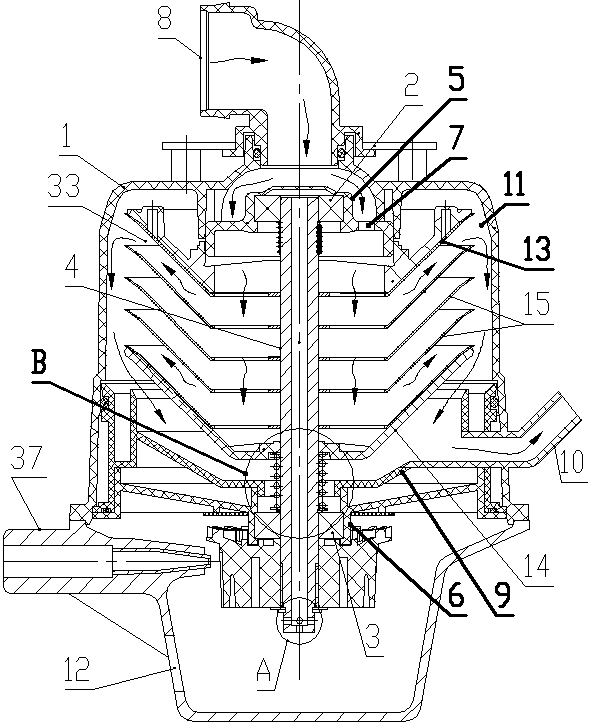

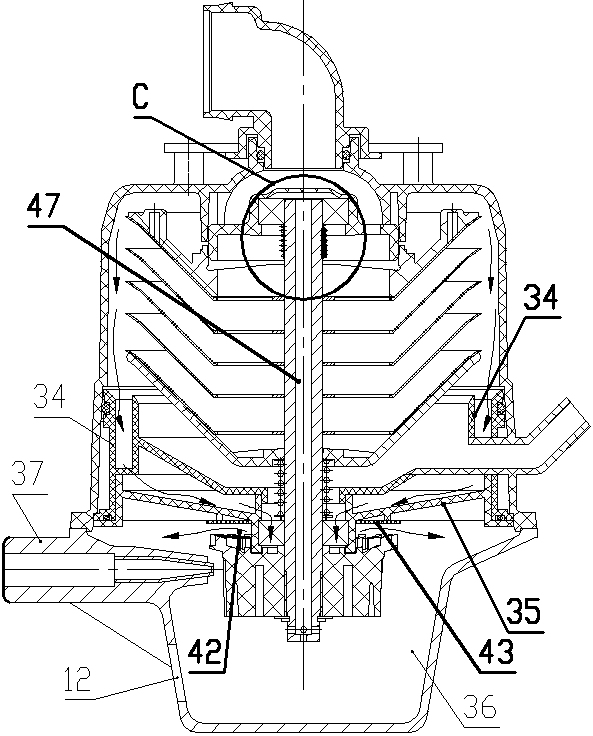

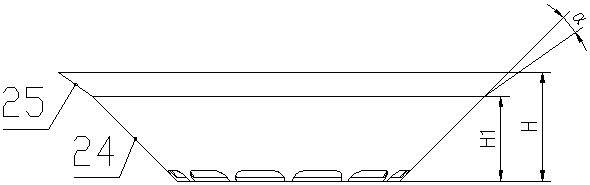

[0055] Such as Figure 1 to Figure 10 As shown, the active oil-gas separator of the present invention includes a housing 1, a central shaft 4 is installed in the housing 1 through an upper bearing 2 and a lower bearing 3, and an oil-gas separation is provided between the middle and upper parts of the central shaft 4 and the housing 1. mechanism, a driving mechanism for driving the rotation of the central shaft 4 is provided between the bottom of the central shaft 4 and the housing 1; the upper bearing 2 is installed on the housing 1 through the upper bearing seat 5, and the lower bearing 3 is installed on the On the shell 1; the upper bearing seat 5 is provided with an installation cavity for accommodating the upper bearing 2, and the upper bearing seat 5 outside the installation cavity is provided with an opening 7 for oil and gas to pass through in the up and down direction;

[0056] The top of the housing 1 is provided with an air inlet 8, and the air inlet 8 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com