Textile cloth drying equipment

A technology for drying equipment and textile fabrics. It is applied in the direction of drying solid materials, drying chamber/container, and drying gas arrangement. It can solve the problems of low drying efficiency and large water vapor, and achieve the effect of speeding up drying and ensuring power transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

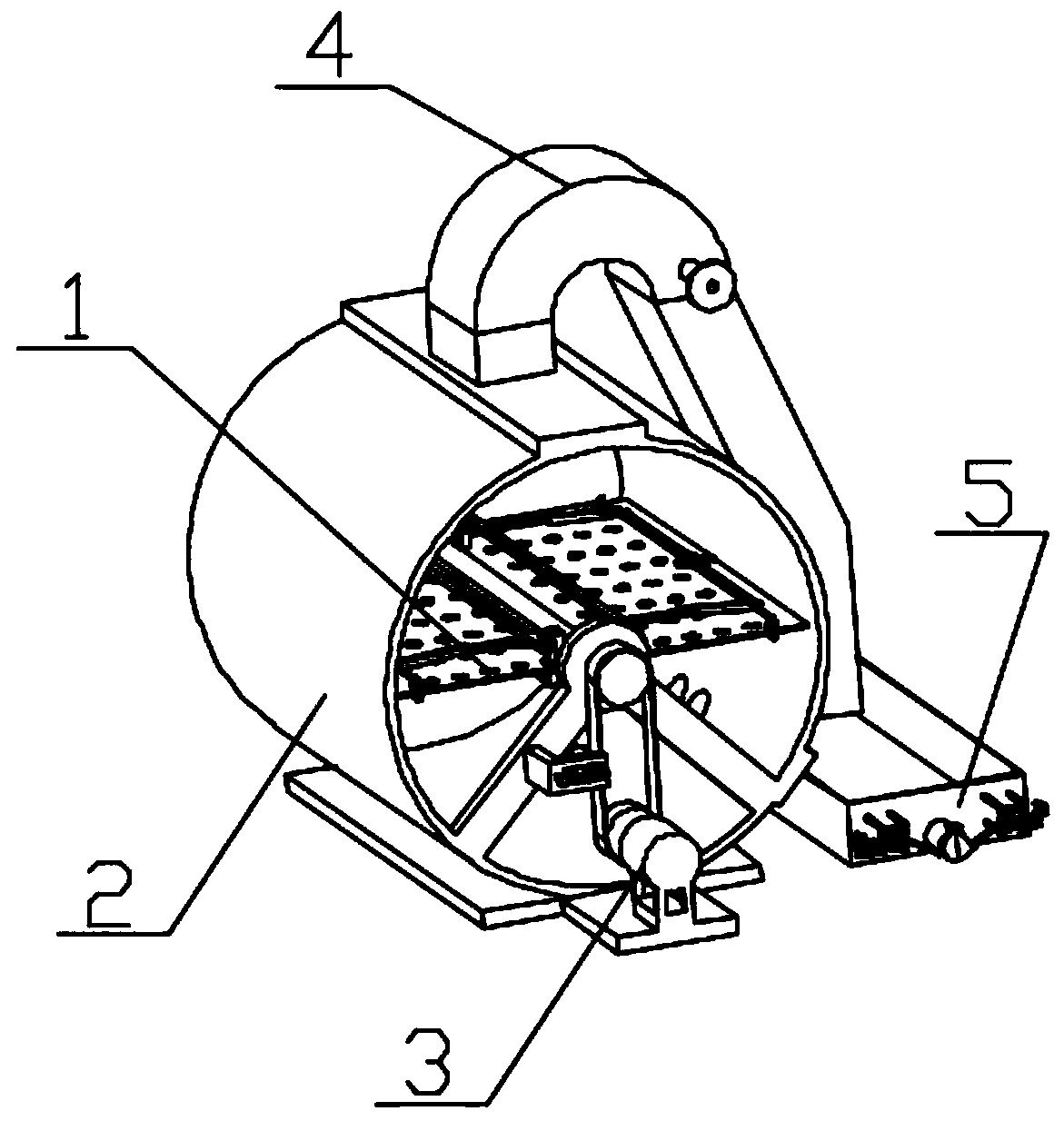

[0041] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 Describe this embodiment, the present invention relates to a kind of drying equipment, more specifically a kind of drying equipment for textile fabrics, including a cloth clamping frame mechanism 1, a body mechanism 2, a power tensioning mechanism 3, a liquid cooling tube mechanism 4, a set The liquid tank mechanism 5, the equipment can accelerate the drying of the cloth, the equipment can ensure the transmission of power, the equipment can guide and cool the water vapor into water for collection, and the equipment can automatically release the water.

[0042] The connection mode between the cloth clamping frame mechanism 1 and the fuselage mechanism 2 is...

specific Embodiment approach 2

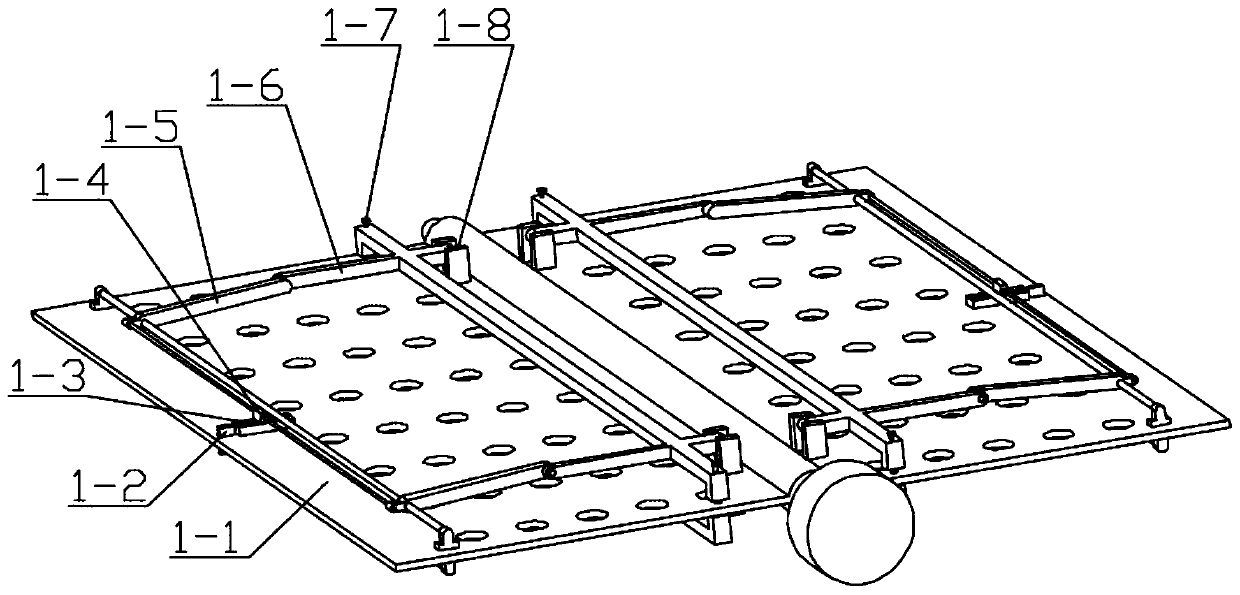

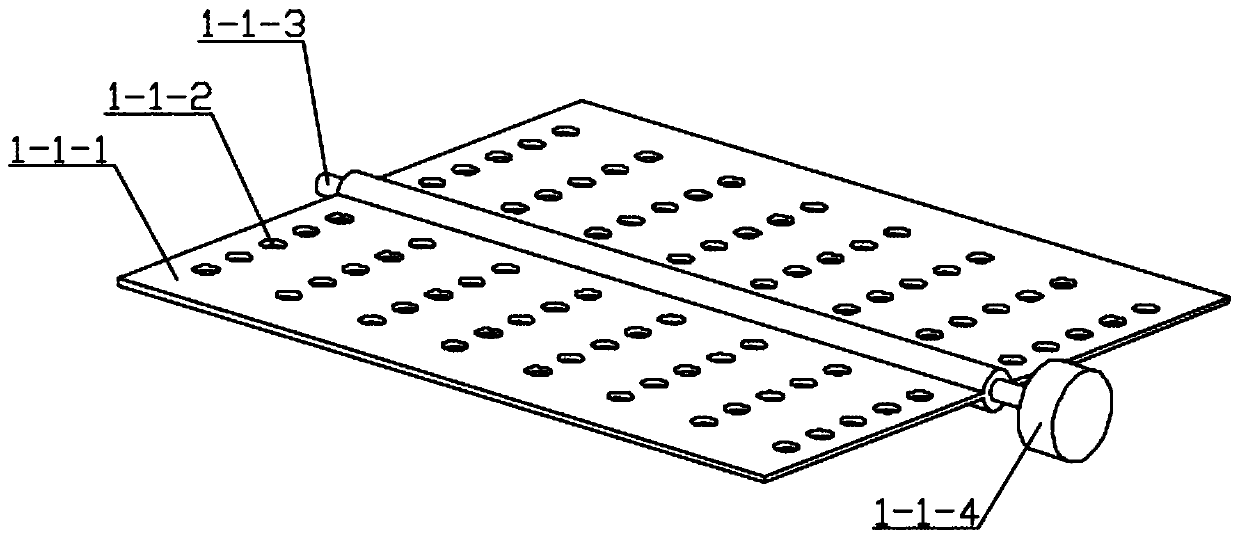

[0044] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 Describe this embodiment, this embodiment will further explain the first embodiment, the cloth clamping frame mechanism 1 includes a frame body mechanism 1-1, a waterproof cover mechanism 1-2, a cloth clamping driving mechanism 1-3, and a cloth clamping linkage mechanism 1-4, edge pressing seat mechanism 1-5, intermediate pressing mechanism 1-6, spring pressing seat mechanism 1-7, hinged seat 1-8, frame body mechanism 1-1 is connected with waterproof cover mechanism 1-2, waterproof The connection mode between the cover mechanism 1-2 and the cloth clamping driving mechanism 1-3 is bearing connection, the cloth clamping driving mechanism 1-3 cooperates with...

specific Embodiment approach 3

[0046] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23Describe this embodiment, this embodiment will further explain the first embodiment, the fuselage mechanism 2 includes a negative pressure fan mechanism 2-1, a cylindrical fuselage 2-2, a connecting seat 2-3, and a bearing seat A2-4 , permeable hole 2-5, negative pressure fan mechanism 2-1 is connected with cylindrical body 2-2, connecting seat 2-3 is connected with cylindrical body 2-2, bearing seat A2-4 is connected with connecting seat 2-3 Connected, the permeable hole 2-5 is opened on the cylinder body 2-2; the negative pressure fan mechanism 2-1 includes a fan motor 2-1-1, a fan coupling 2-1-2, a ring plate 2-1- 3. Negative pressure blade 2-1-4, fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com