Needling machine transmission mechanism vibration signal feature extraction method

A vibration signal, transmission mechanism technology, applied in the testing of machine/structural components, testing of mechanical components, measuring devices, etc., can solve modal confusion, discontinuous points of hard threshold function discontinuity, constant deviation of soft threshold function, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

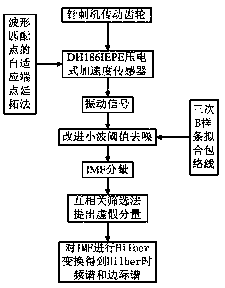

Method used

Image

Examples

Embodiment Construction

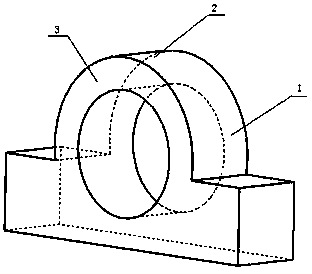

[0056] attached figure 2 Middle: 1. Horizontal measuring point 2. Vertical measuring point 3. Axial measuring point.

[0057] 1. Signal acquisition

[0058] The acceleration sensor is used to collect the vibration signal of the transmission mechanism of the acupuncture machine. The sensor used in this application is a DH186IEPE piezoelectric acceleration sensor with a sensitivity of 0~10mV / ms -2 , range is 500m / s 2 , frequency range 0.5~5kHz. The acquisition box is DH-5923 dynamic signal test analyzer from Donghua Testing Company. Acceleration sensors are arranged in three directions, namely horizontal direction, vertical direction and axial direction. The axial direction is to detect the centering degree of the transmission mechanism of the acupuncture machine, and the signals in the horizontal and vertical directions reflect the fault characteristics of the transmission mechanism of the acupuncture machine.

[0059] 3. Endpoint processing of the signal using the autoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com