System for testing surrounding rock characteristics of impact hole

A technology of property testing and hole surrounding rock, applied in the direction of strength properties, the use of repetitive force/pulse force to test the strength of materials, measuring devices, etc., can solve problems such as no clear specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

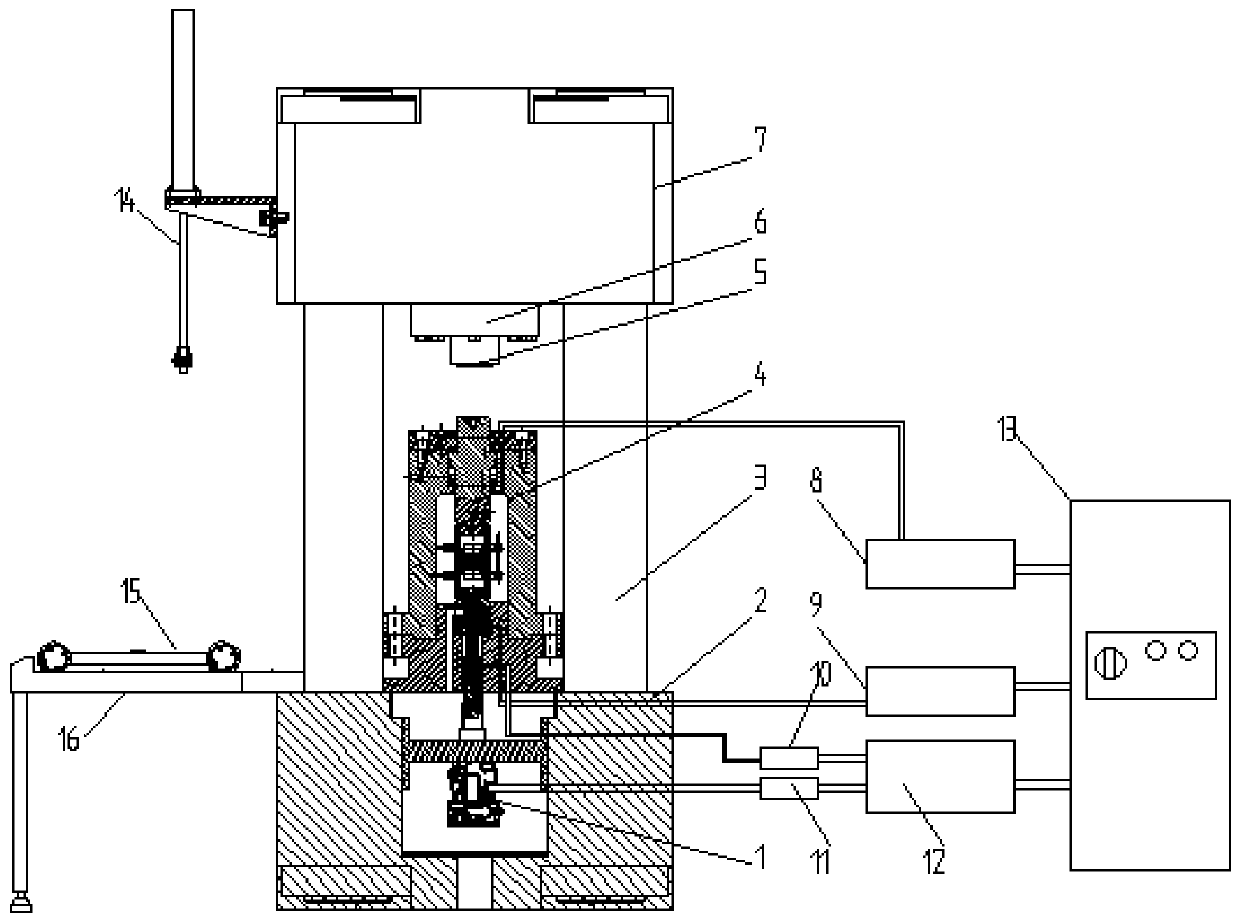

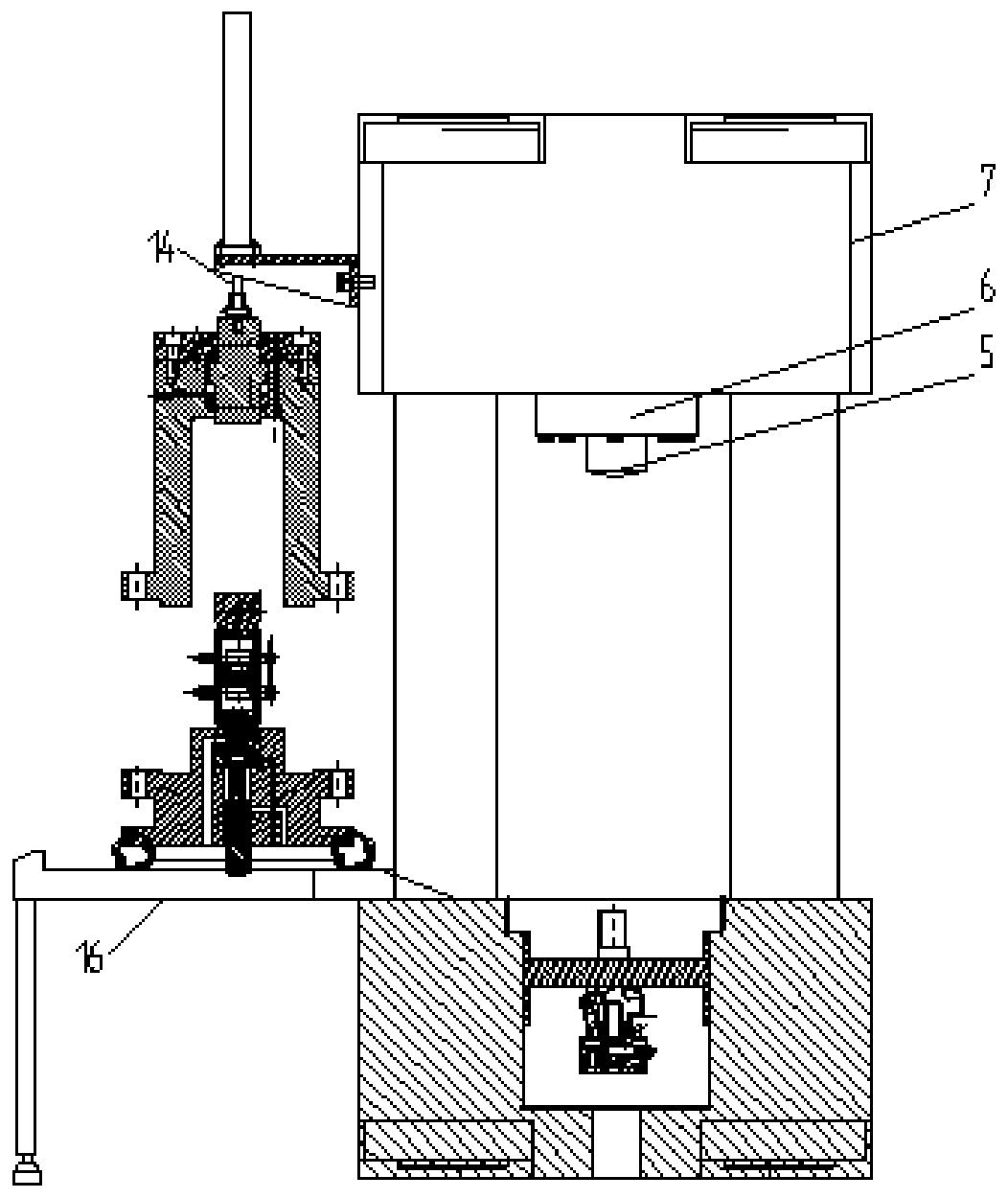

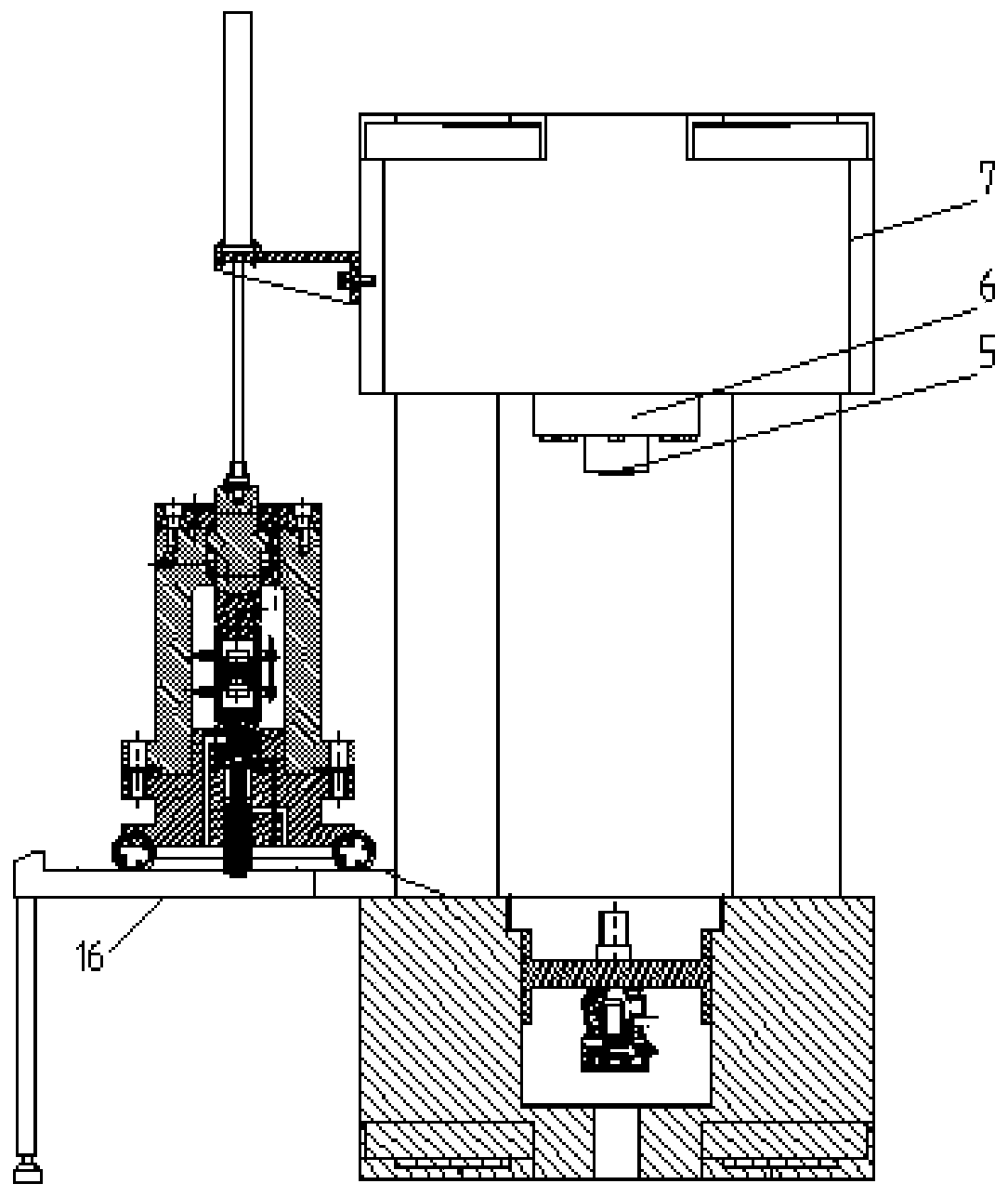

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as Figure 1 to Figure 7 , a system for testing the characteristics of surrounding rock in impact holes in the present invention, including a frame, a hydraulic motor 1, a pressure chamber assembly 4, a pressure rod 5, a supercharger 8, an air compressor 9, a servo valve 10, and an electro-hydraulic proportional valve 11. Oil source 12, upper pressure head 18, axial extensometer 21, impact drill bit 22, vibration cylinder 29, radial extensometer 31, rock sample 32 and sealing sleeve 33.

[0031] The pressure chamber assembly 4 is placed on the frame, and a test chamber 40 is provided on the pressure chamber assembly 4. The upper indenter 18 is plugged into the pressure chamber assembly 4, and one end of the upper indenter 18 extends to the pressure chamber assembly. into 4 test chambers 40. The hydraulic motor 1 is fixed on the frame, and the output shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com