Method for determining the short-circuit capacity of collector lines and busbars in wind farms

A technology of busbar and short-circuit capacity, applied in the field of wind power, can solve the problems of difficulty in real-time monitoring, low accuracy, and low practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

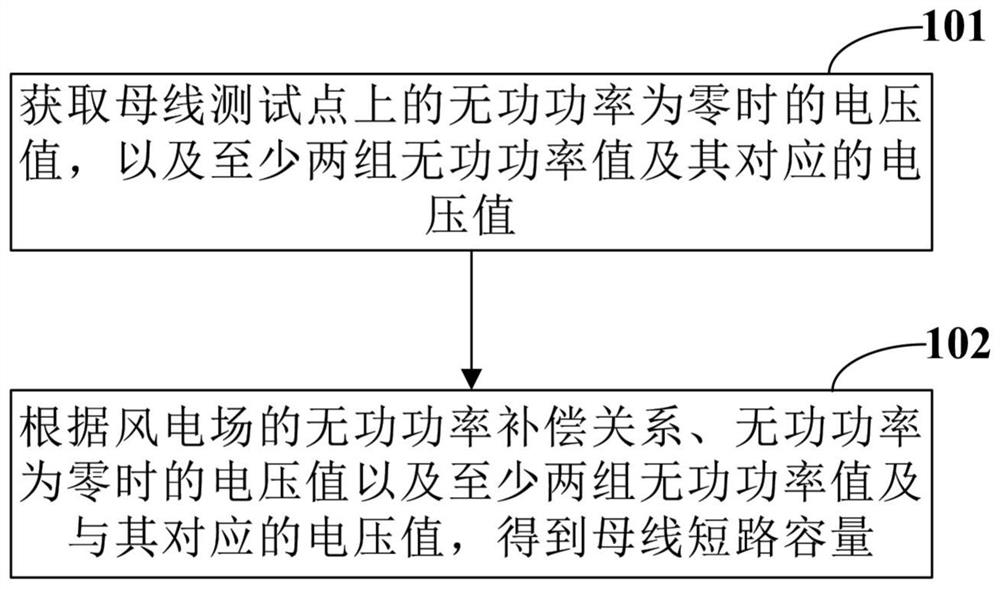

[0020] figure 1 It is a schematic flow chart of the method for testing the bus short-circuit capacity of Embodiment 1 of the present invention, which can be performed on the bus short-circuit capacity test device as described in Embodiment 2, such as figure 1 As shown, in the running state of the wind farm, the bus short-circuit capacity test method includes:

[0021] Step 101: Obtain the voltage value when the reactive power of the test point on the bus is zero, and at least two sets of reactive power values and corresponding voltage values.

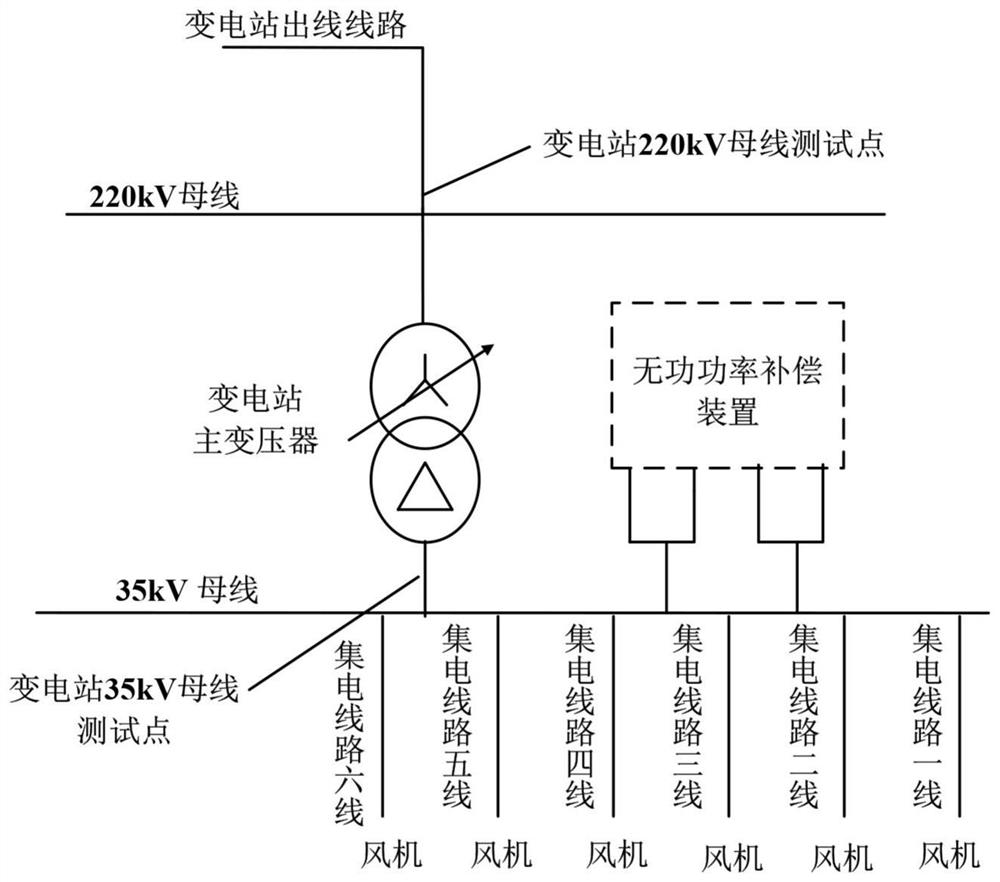

[0022] It should be noted that the busbar may specifically be a grid-connected busbar and / or a collector busbar.

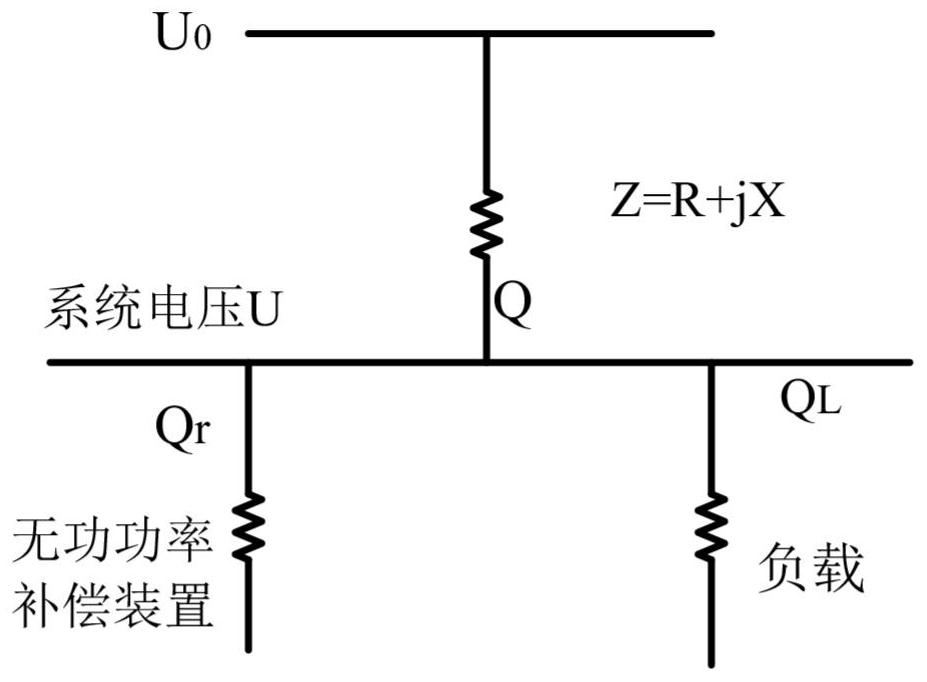

[0023] Here, the wind farm may include a reactive power compensation device. According to an exemplary embodiment of the present invention, step 101 may include: adjusting the output capacity of the reactive power compensation device to detect when the reactive power of the test point on the bus is zero , and at least t...

Embodiment 2

[0062] Figure 9 It is a schematic structural diagram of a busbar short-circuit capacity testing device according to Embodiment 2 of the present invention. It can be used to execute the steps of the busbar short-circuit capacity testing method in Embodiment 1 of the present invention.

[0063] refer to Figure 9, the bus short-circuit capacity test device includes a power and voltage acquisition module 901 and a short-circuit capacity calculation module 902 .

[0064] The power and voltage acquisition module 901 is used to acquire the voltage value when the reactive power of the test point on the bus is zero, and at least two groups of reactive power values and corresponding voltage values.

[0065] The short-circuit capacity calculation module 902 is used to obtain the bus short-circuit capacity according to the reactive power compensation relationship of the wind farm, the voltage value when the reactive power is zero, and at least two sets of reactive power values and...

Embodiment 3

[0077] The busbar short-circuit capacity test system includes an acquisition device and a processor. Wherein, the acquiring device is used to acquire the voltage value when the reactive power of the test point on the bus is zero, and at least two groups of reactive power values and corresponding voltage values. The processor is used to obtain the bus short-circuit capacity according to the reactive power compensation relationship of the wind farm, the voltage value when the reactive power is zero, and at least two sets of reactive power values and their corresponding voltage values.

[0078] It should be noted that the acquisition device may specifically be, but not limited to, a power quality tester, or other power and voltage detection equipment.

[0079] The busbar short-circuit capacity testing system of the present invention obtains the voltage value when the reactive power of the test point on the busbar is zero, and at least two sets of reactive power values and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com