A durability test system for concrete repair agent

A technology of durability test and repair agent, applied in the direction of instruments, material electrochemical variables, measuring devices, etc., can solve the problem of not being able to meet the durability test at the same time, and achieve the effect of improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

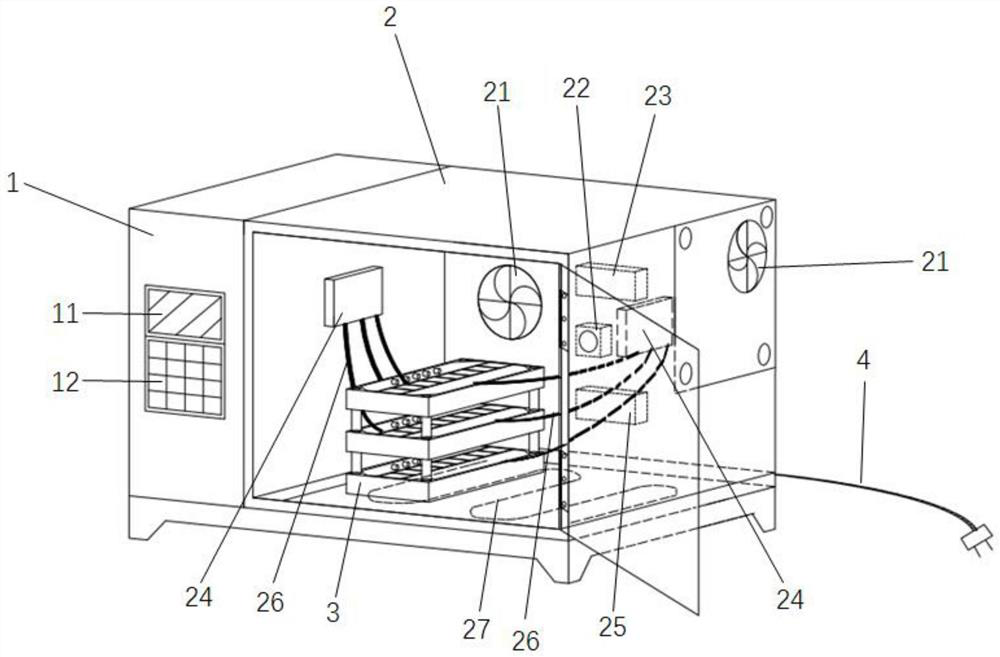

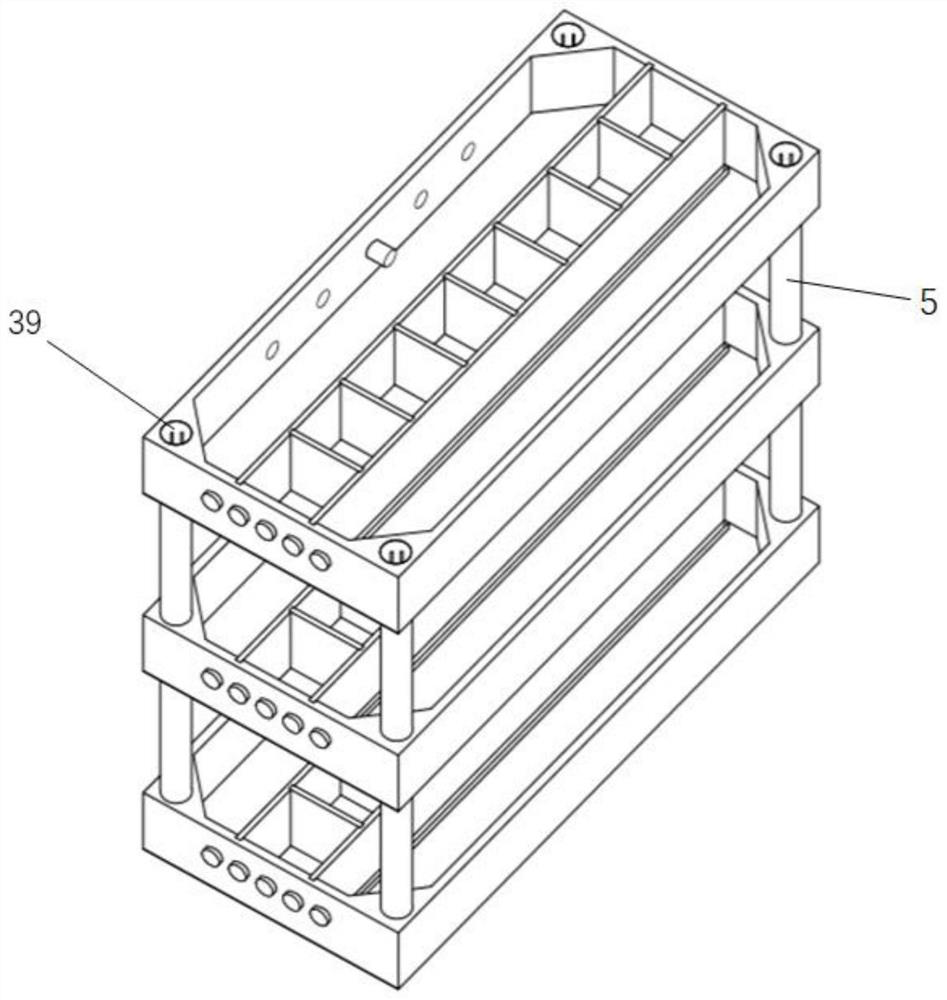

[0051] Such as Figure 1~4 A concrete repair agent durability test system shown includes a box body 2, three test boxes 3 placed in the box body 2 and stacked along the height direction, and a central control system 1 installed on the left side of the box body 2. The inner wall of the body 2 is fixedly installed with a liquid storage tank 24 for placing a corrosive solution. The liquid storage tank 24 communicates with the test box 3 through an infusion pipeline 26, and the central control system 1 controls the injection of the corrosive solution in the test box 3 into the test box. 3. The solution storage area realizes the automation of corrosive solution injection. The corrosive solution is sodium sulfate, magnesium sulfate, sodium chloride, etc. A heating pipe 27, a condenser 23, a humidifier 25, a ventilation fan 21, an ultraviolet lamp 22, a sensor and an internal integrated circuit connected with the central control system 1 are also installed in the casing 2. The centr...

Embodiment 2

[0058] Such as Figure 1~3 and Figure 5 The difference between embodiment 2 and embodiment 1 of the shown durability test system for concrete repair agent is that only the second inserting plate 362 and the second inserting plate 362 are inserted between the first partition 331 and the second partition 332 The four inserting plates 364 and the sixth inserting plate 366 form four chambers, which are chamber one, chamber two, chamber three, and chamber four from left to right. Fill chambers one and three with ordinary concrete, and after curing, Remove the second board 362 and the sixth board 366, fill the second and fourth chambers with concrete restoration agents such as magnesium phosphate cement mortar, epoxy resin modified mortar, etc., and form two 40*40*160 for curing Specimens for flexural tests.

[0059] After the molded test piece is cured to the expected strength, the first partition 331 and the second partition 332 are removed, the test box 3 is placed in the box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com