Server board burning prevention system and working method

A working method and anti-burning board technology, applied in instruments, electrical digital data processing, computing, etc., can solve the problem that the overcurrent protection point is too large, the internal overcurrent protection function of the PSU power supply cannot effectively protect, and the server system cannot be restored issues such as sexual destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

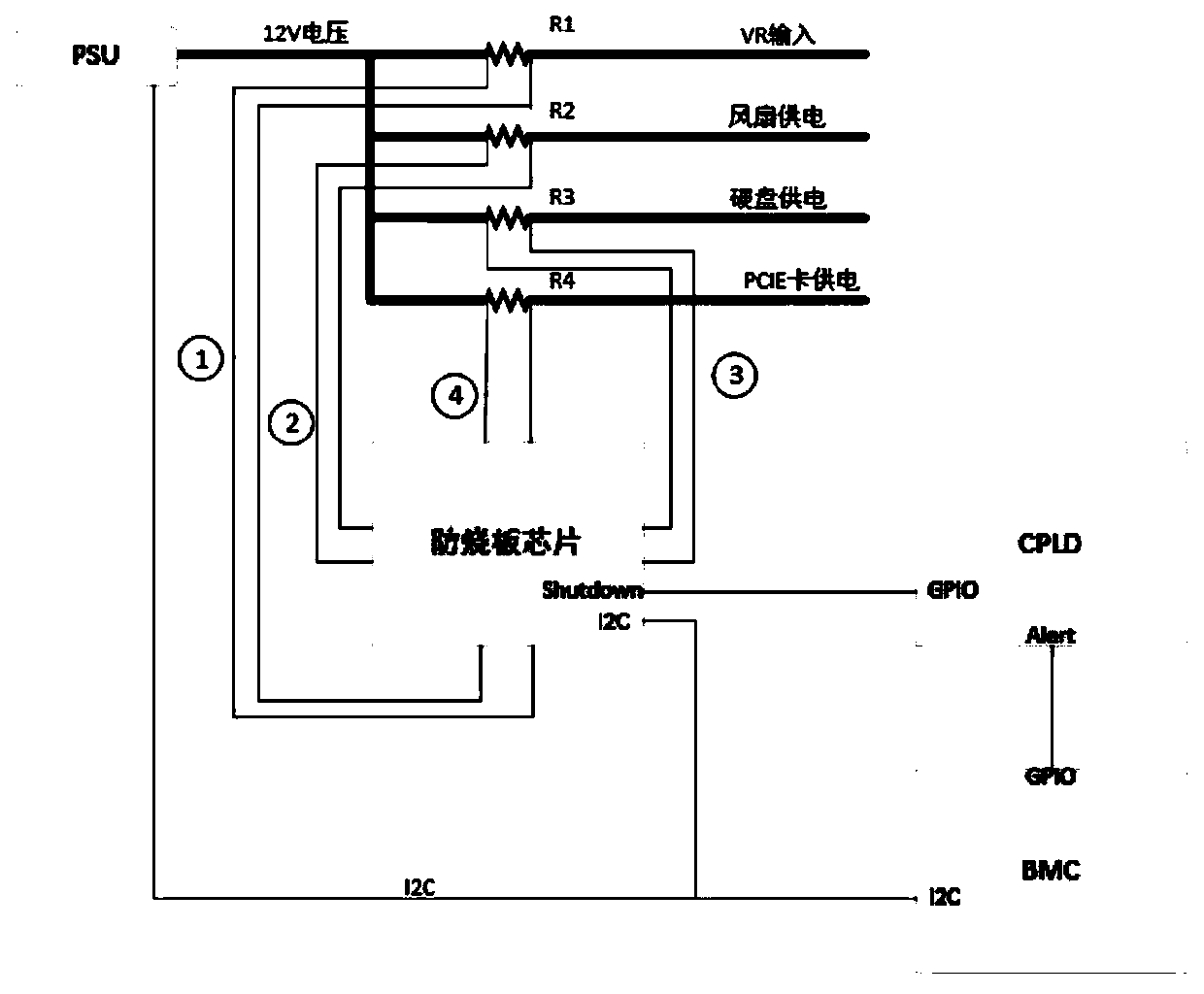

[0029] Embodiment 1 of the present invention provides a server anti-burn board system and working method,

[0030] The system includes power module, anti-burn board chip, BMC and CPLD;

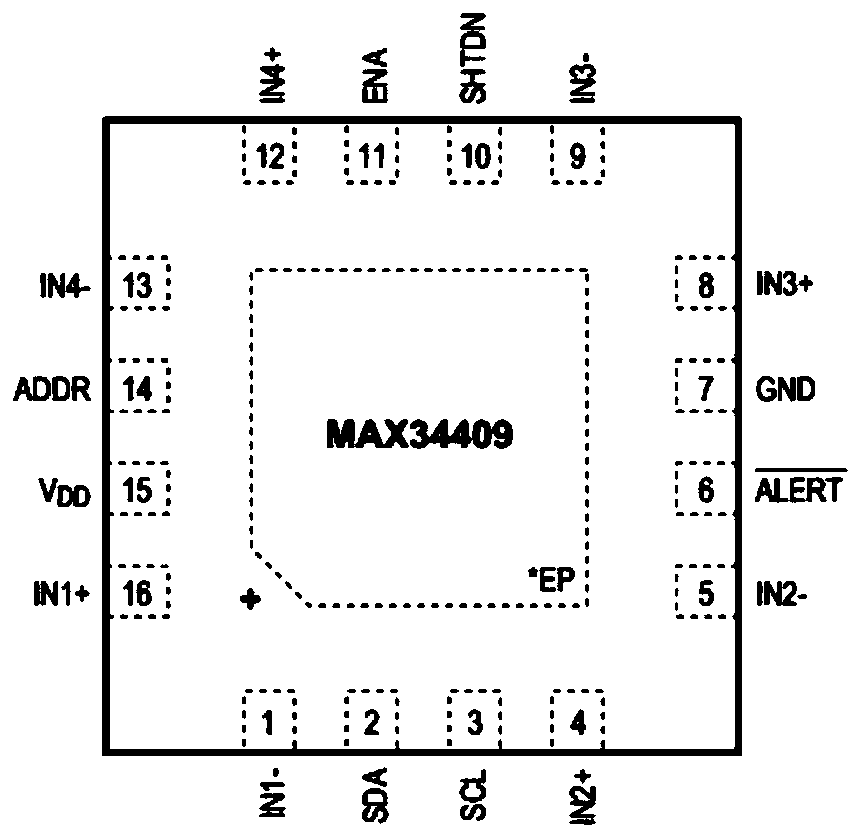

[0031] The power supply module supplies the output 12V power supply to different parts of the server through several parallel resistors; the anti-burn board chip is connected to the output and output terminals of the resistors through differential lines to monitor the working current of the power supply line;

[0032] The anti-burn board chip is connected to CPLD through GPIO signal; CPLD is connected to BMC via GPIO signal. BMC is also connected to the anti-burn board chip and power module through I2C signal; when any power supply line has overcurrent, the anti-burn board chip outputs shutdown signal to CPLD; After receiving the shutdown signal, the CPLD sends an interrupt signal to the BMC; after receiving the interrupt signal, the BMC determines the address where the overcurrent occurs, and saves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com