An advanced material control system for industrial inkjet printers

A control system, inkjet printer technology, applied in thin material handling, transportation and packaging, function indication, etc., can solve the problems of ineffective alarm circuit, damage to the receiving/discharging motor, false alarm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

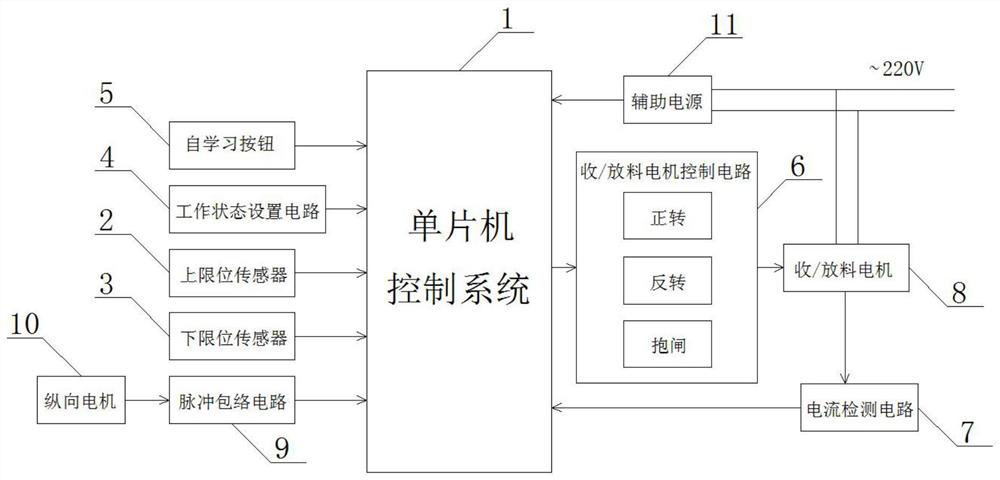

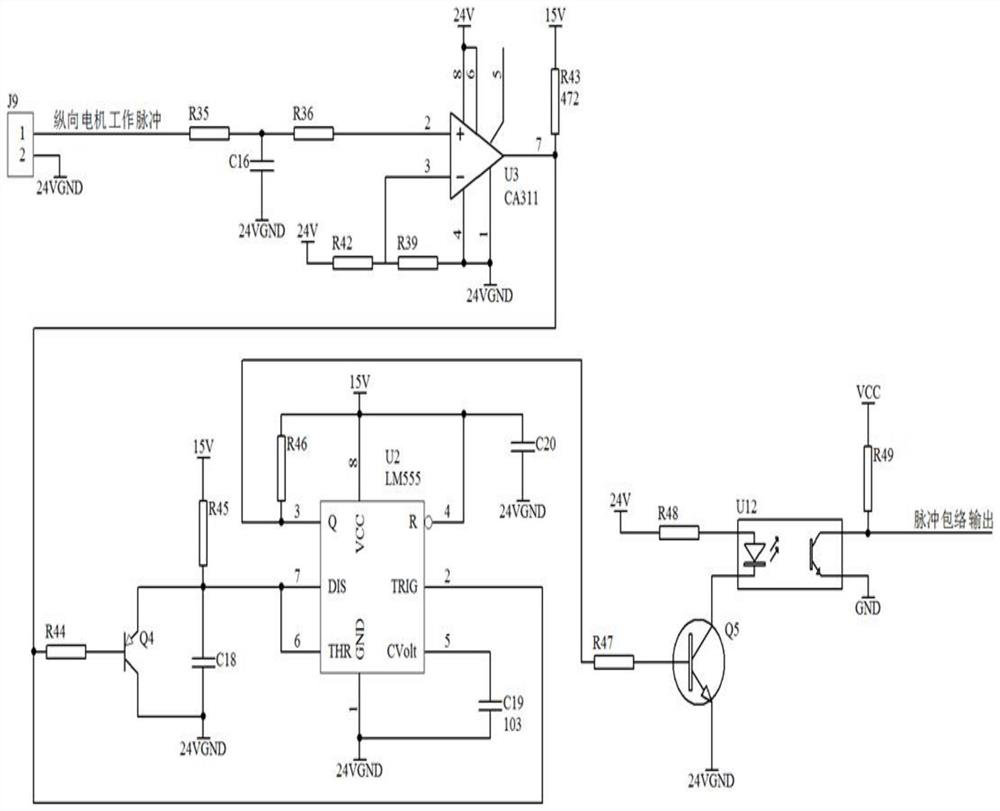

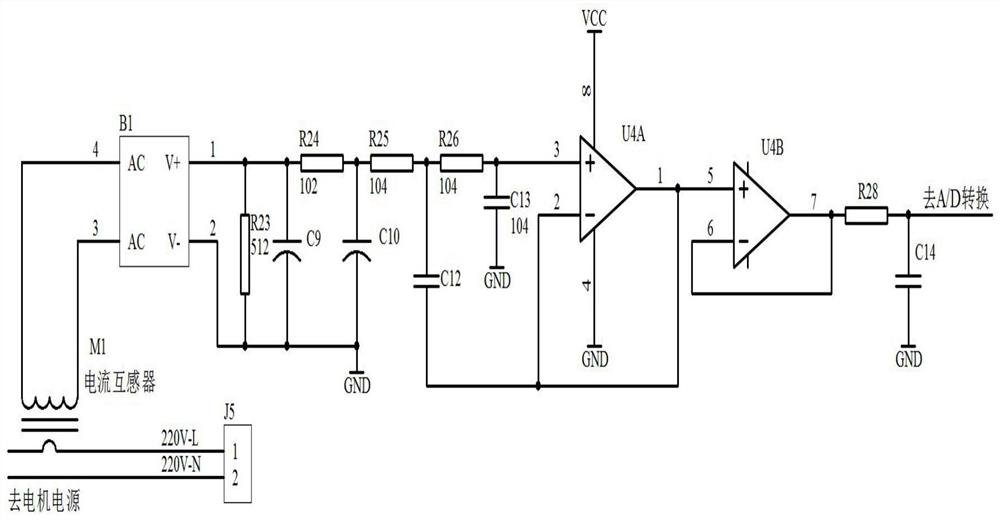

[0023] see Figure 1 to Figure 4 , the present invention provides a technical solution: an advanced industrial inkjet machine retractable material control system, including a single-chip microcomputer control system 1, an upper limit sensor 2, a lower limit sensor 3, a working state setting circuit 4, a self-learning button 5, a retractable / Discharging motor control circuit 6, current detection circuit 7, receiving / discharging motor 8, pulse envelope circuit 9, longitudinal motor 10 and auxiliary power supply 11, described single-chip microcomputer control system 1 is connected with longitudinal motor 10 by pulse envelope circuit 9 Electrically connected, the single-chip control system 1 is electrically connected with the receiving / discharging mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com