High-efficiency slot milling, wire picking and packaging device for intelligent card

A technology of packaging device and thread take-up device, which is applied in the direction of recording carriers used in machines, instruments, computer parts, etc., can solve the problems of unable to meet the production line efficiency, reduce production efficiency, and small thread take-up angle, so as to save production time, The effect of improving efficiency and increasing the speed of thread take-up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

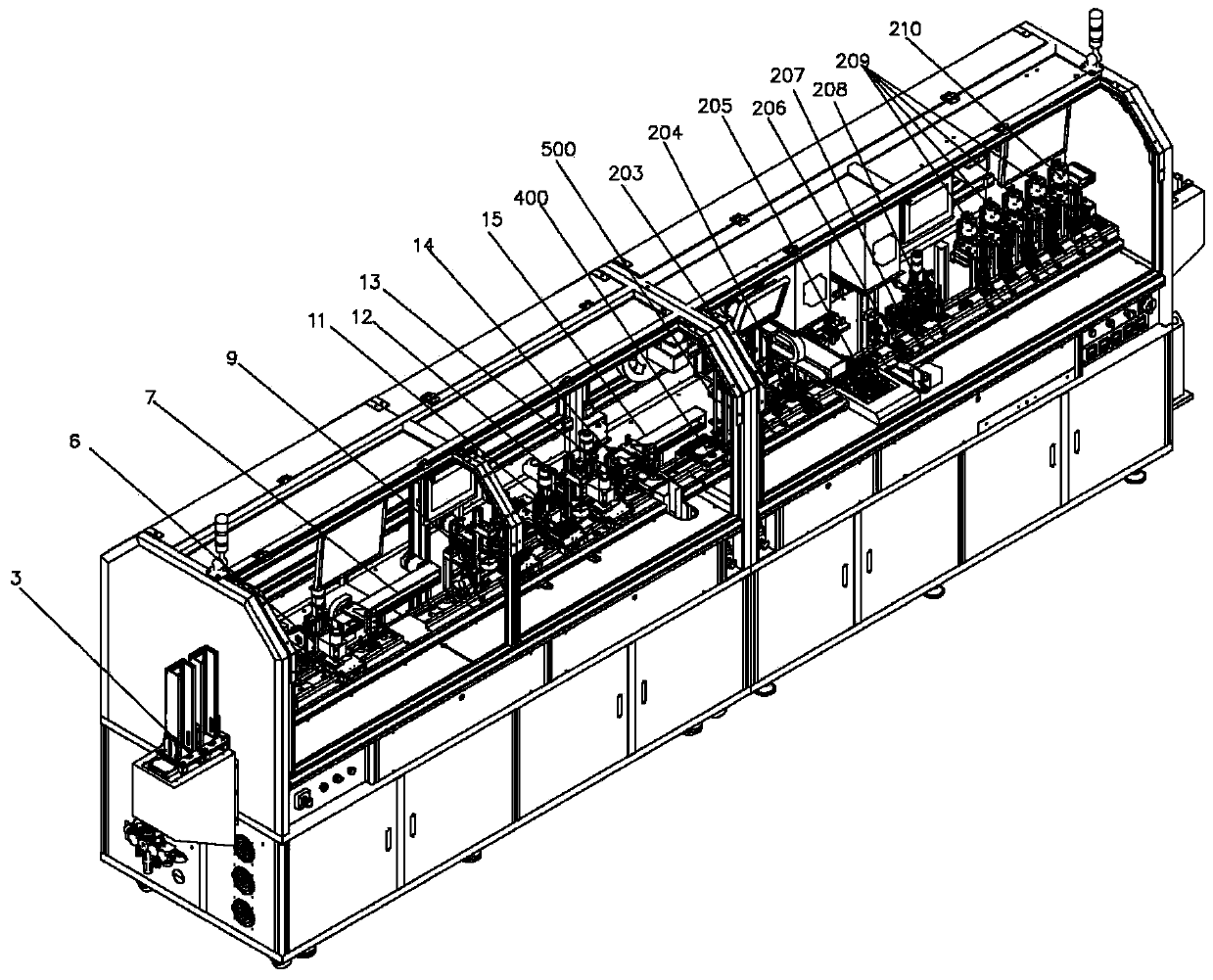

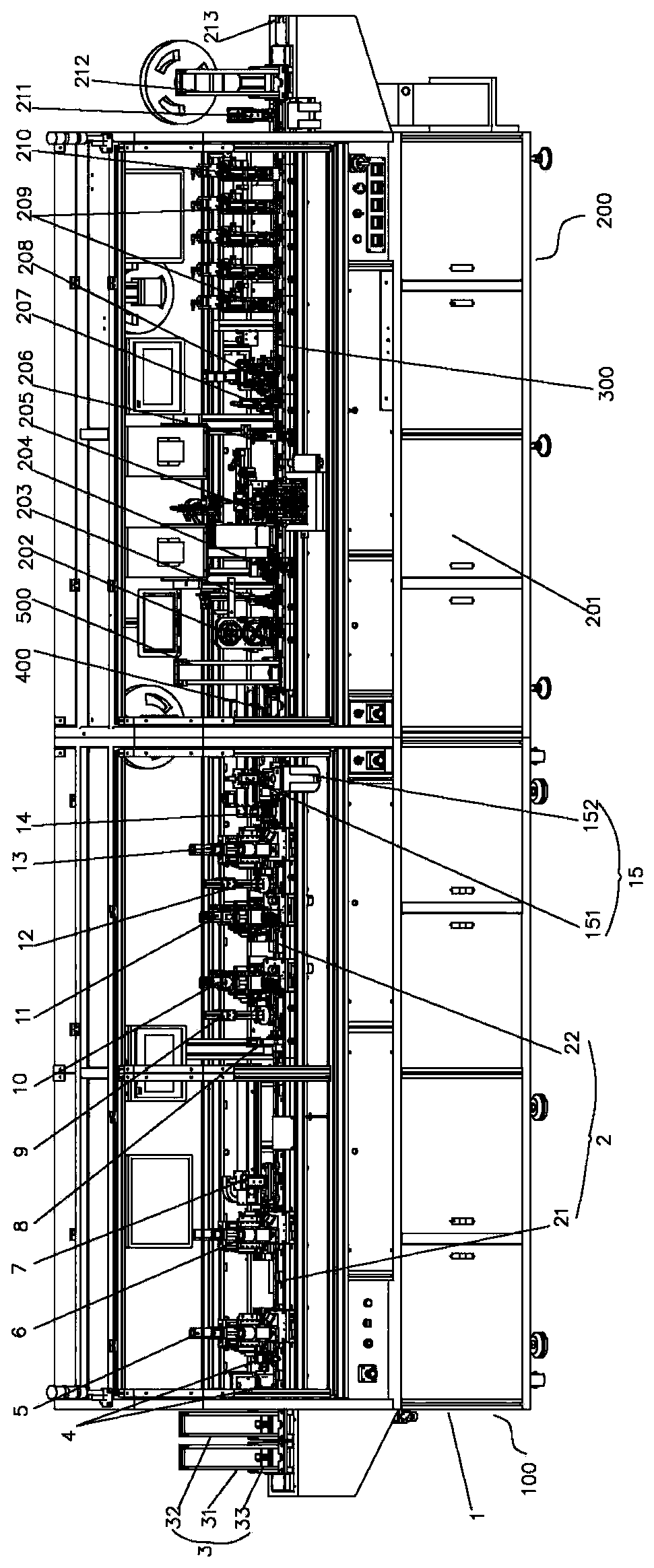

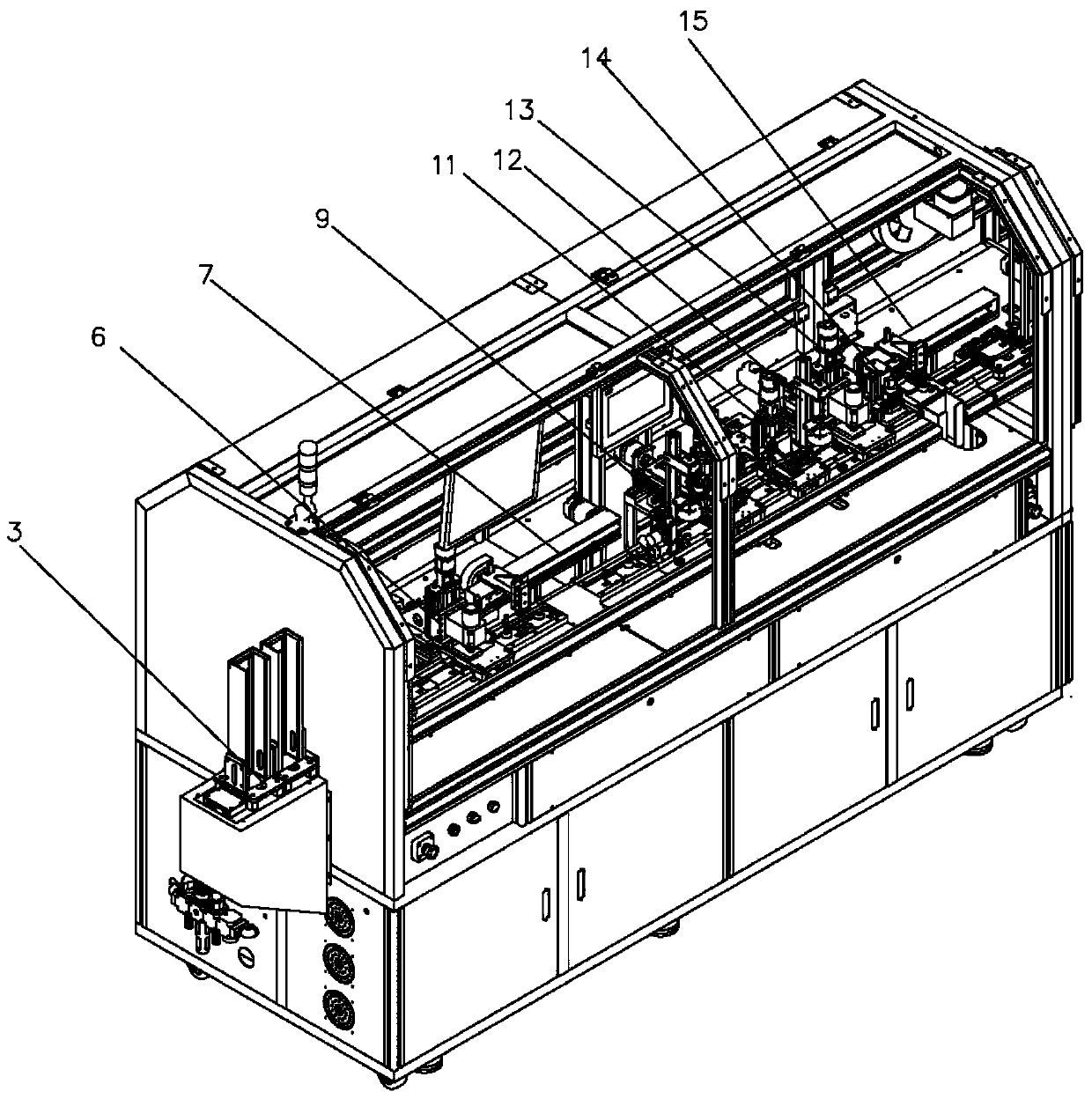

[0055] Such as Figure 1 to Figure 7 As shown, a smart card high-efficiency milling groove take-up packaging device includes a smart card high-efficiency milling groove take-up device 100 and a smart card high-efficiency packaging device 200. The device 200 is provided with a rear card conveying line 300, and the junction of the front card conveying line 2 and the rear card conveying line 300 is provided with a qualified product card buffer stacker 400 and a manual card stacker 500, and a qualified product card buffer stacker 400 and manual The card stacking racks 500 are used alternately. The front card conveying line 2 includes a front conveying line 21 for simultaneously conveying two cards and a rear conveying line 22 for conveying single cards one by one. The rear card conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com