A device for improving the uniformity of stator axial temperature distribution

A technology of temperature distribution and uniformity, applied in the direction of electromechanical devices, magnetic circuit shape/style/structure, casing/cover/support, etc., can solve the problem of uneven axial wind speed in the stator wind channel and the inability to effectively reduce the stator coil and the axial temperature difference of the iron core to achieve the effect of easy implementation, simple structure and uniform axial wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

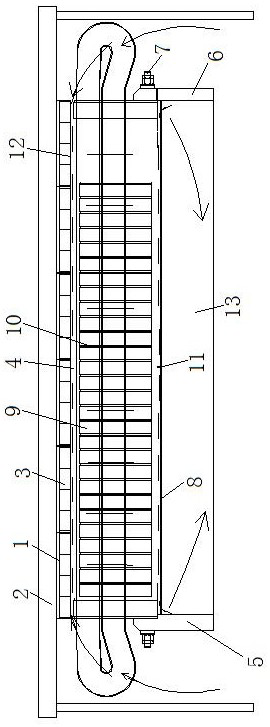

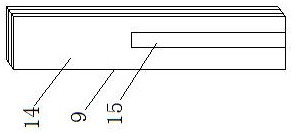

[0030] see figure 1 and figure 2 , a device for improving the uniformity of stator axial temperature distribution, comprising a rotor core 1 and a rotor frame 2, the rotor core 1 is installed on the rotor frame 2, and a plurality of rotor magnets 3 are fixed on the rotor core 1, A plurality of rotor magnetic steels 3 are arranged along the axial direction of the rotor core 1, and also include a stator core 4, a stator pressure plate 1, a stator pressure plate 2 6, a core-through screw 7 and an axial ring plate 8, and the stator core 4 includes multiple A core segment 9, a stator wind trench 10 is arranged between any two adjacent core segments 9, and the plurality of core segments 9 are connected by a core screw 7, and one end of the core screw 7 is fixedly connected with the stator pressure plate-5, The other end is fixedly connected to the stator pressure plate 2 6, an axial ring plate 8 is fixedly connected between the stator pressure plate 1 5 and the stator pressure pla...

Embodiment 2

[0033] see figure 1 and figure 2, a device for improving the uniformity of stator axial temperature distribution, comprising a rotor core 1 and a rotor frame 2, the rotor core 1 is installed on the rotor frame 2, and a plurality of rotor magnets 3 are fixed on the rotor core 1, A plurality of rotor magnetic steels 3 are arranged along the axial direction of the rotor core 1, and also include a stator core 4, a stator pressure plate 1, a stator pressure plate 2 6, a core-through screw 7 and an axial ring plate 8, and the stator core 4 includes multiple A core segment 9, a stator wind trench 10 is arranged between any two adjacent core segments 9, and the plurality of core segments 9 are connected by a core screw 7, and one end of the core screw 7 is fixedly connected with the stator pressure plate-5, The other end is fixedly connected to the stator pressure plate 2 6, an axial ring plate 8 is fixedly connected between the stator pressure plate 1 5 and the stator pressure plat...

Embodiment 3

[0041] see figure 1 and figure 2 , a device for improving the uniformity of stator axial temperature distribution, comprising a rotor core 1 and a rotor frame 2, the rotor core 1 is installed on the rotor frame 2, and a plurality of rotor magnets 3 are fixed on the rotor core 1, A plurality of rotor magnetic steels 3 are arranged along the axial direction of the rotor core 1, and also include a stator core 4, a stator pressure plate 1, a stator pressure plate 2 6, a core-through screw 7 and an axial ring plate 8, and the stator core 4 includes multiple A core segment 9, a stator wind trench 10 is arranged between any two adjacent core segments 9, and the plurality of core segments 9 are connected by a core screw 7, and one end of the core screw 7 is fixedly connected with the stator pressure plate-5, The other end is fixedly connected to the stator pressure plate 2 6, an axial ring plate 8 is fixedly connected between the stator pressure plate 1 5 and the stator pressure pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com