Production process of lap welding flexible connecting piece of new energy battery and product thereof

A production process and lap welding technology, which is applied in the direction of welding/welding connection, connection, contact manufacturing, etc., can solve problems such as cracks at bends, difficult bending of battery connecting pieces, and shortened service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0028] Please refer to figure 1 , an embodiment of the present invention provides a production process of a new energy battery lap welding soft connection sheet, including the following steps:

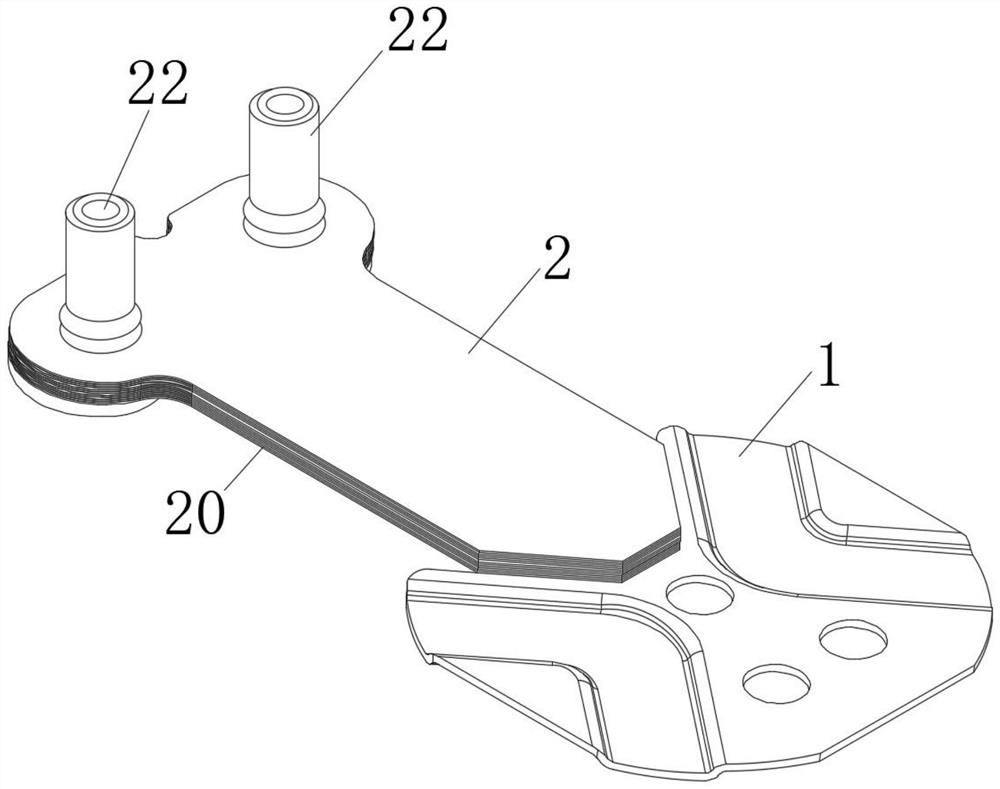

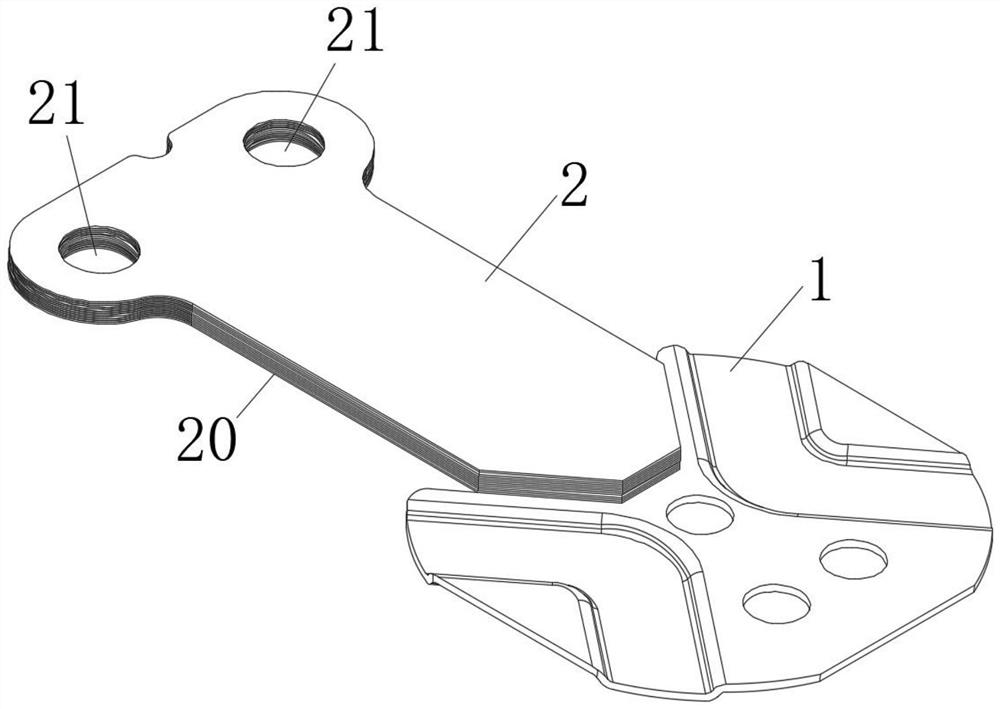

[0029] (1) Making a multi-layer soft adapter piece 2 and forming a hard collector plate 1;

[0030] (2) Lap the hard collector plate 1 with the multi-layer soft adapter piece 2 to form a semi-finished product;

[0031] (3) Stamping and forming the multi-layer soft adapter sheet 2 on the semi-finished product, flushing away the excess material, punching out the required shape, and punching out at least one welding hole 21, such as figure 2 shown;

[0032] (4) welding the upper pole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com