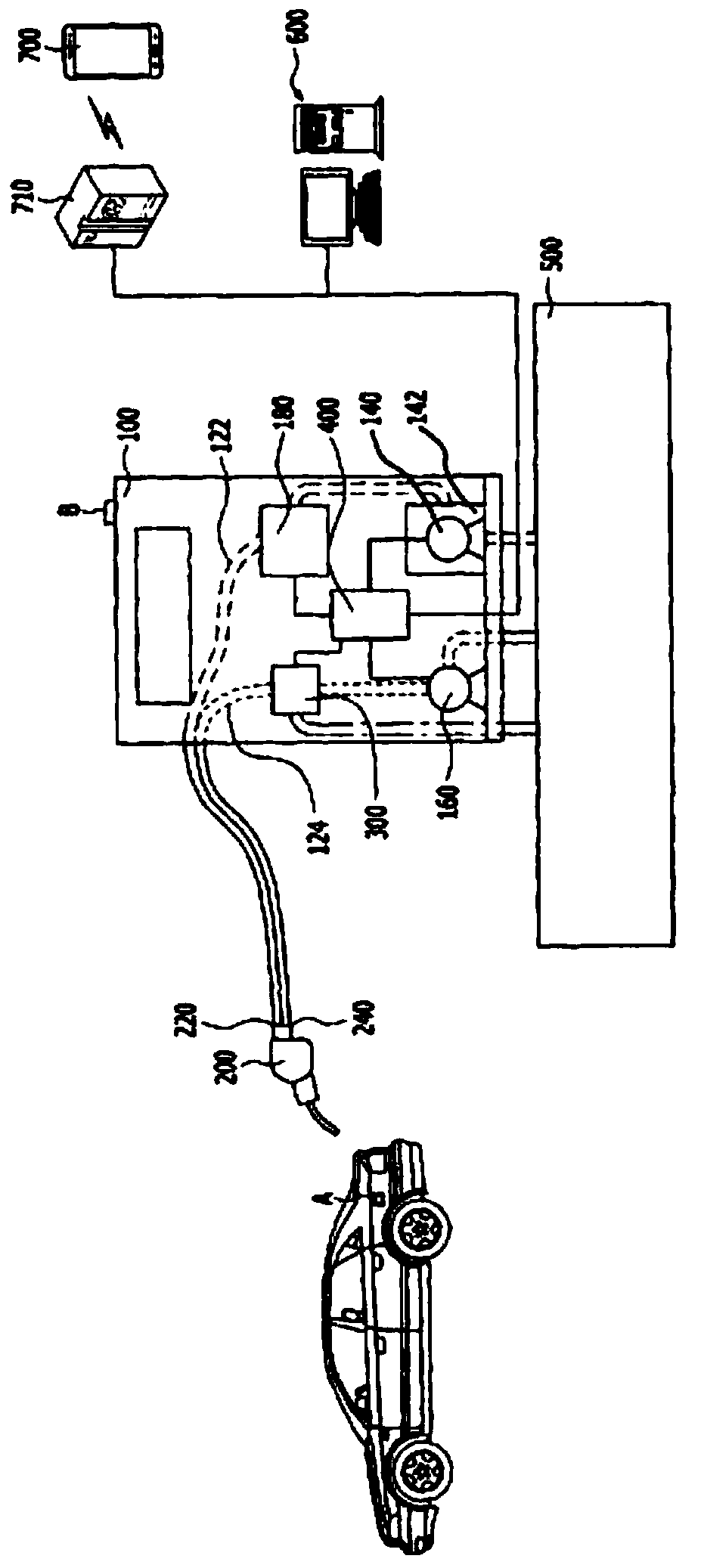

Oil mist collection monitoring system

A monitoring system and oil mist technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of not considering the amount of oil leakage and how to deal with oil mist, so as to protect health and environment and prevent fires , The effect of solving the oil leakage problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

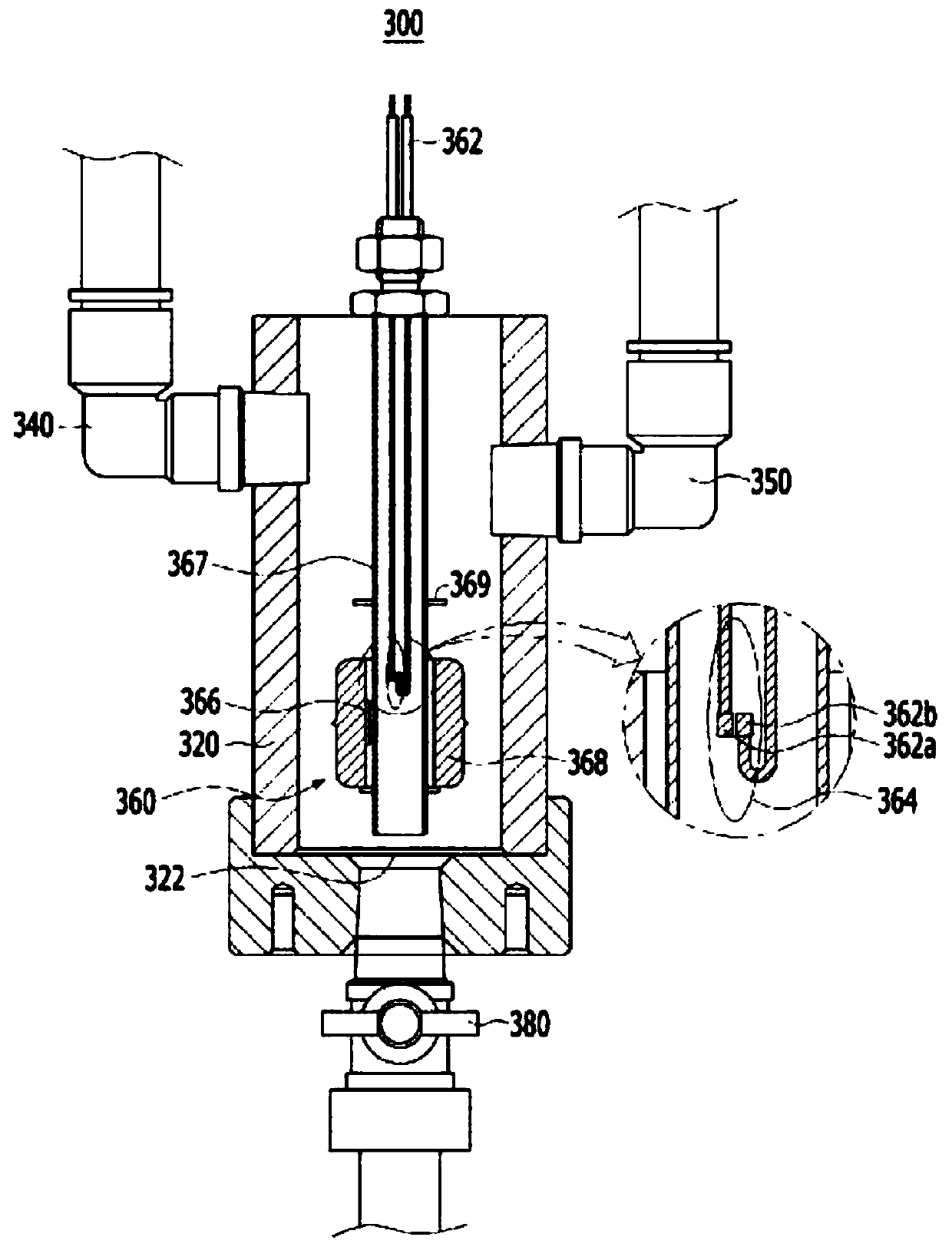

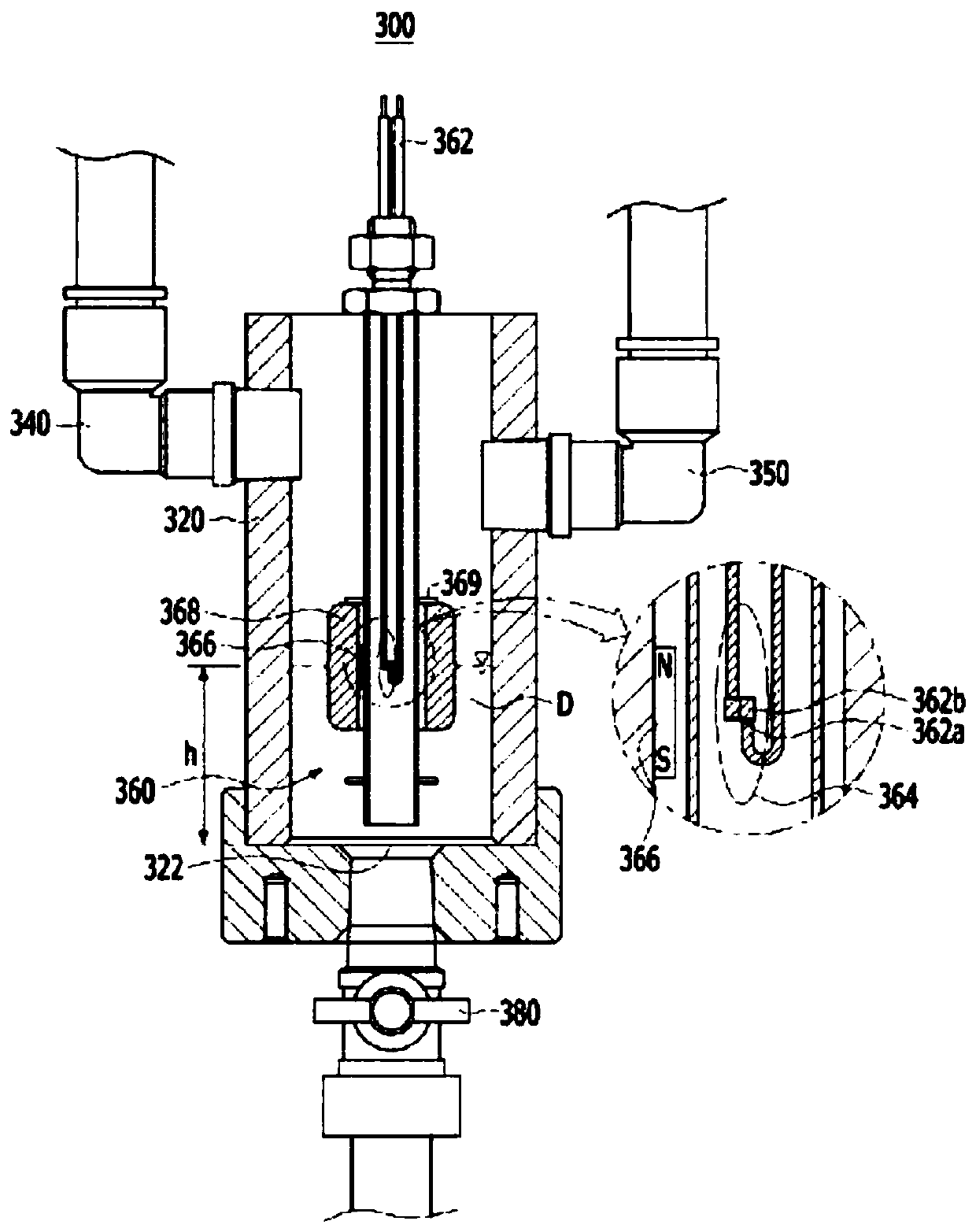

Embodiment Construction

[0037] The present invention can be implemented in other various ways without departing from its technical idea or main features. Therefore, various aspects of the embodiments of the present invention are merely examples and should not be construed in a limited manner.

[0038] The terms of first, second, etc. are used only for the purpose of distinguishing one constituent element from other constituent elements. For example, without departing from the scope of rights of the present invention, a first constituent element may be named a second constituent element, and similarly, a second constituent element may also be named a first constituent element.

[0039] When certain elements are referred to as being "connected to" or "connected to" other elements, it may be directly connected or connected to the other elements, however, other elements may also be present in between.

[0040] In the present application, the singular form used includes the plural form as long as there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com